Roofing product

a technology for roofs and products, applied in the field of roofs, can solve the problems of reducing affecting the installation of semi-rigid to rigid shingles with a starter course, and requiring special tools, so as to reduce the size of hidden gaps, and improve the distribution of impact force loads

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

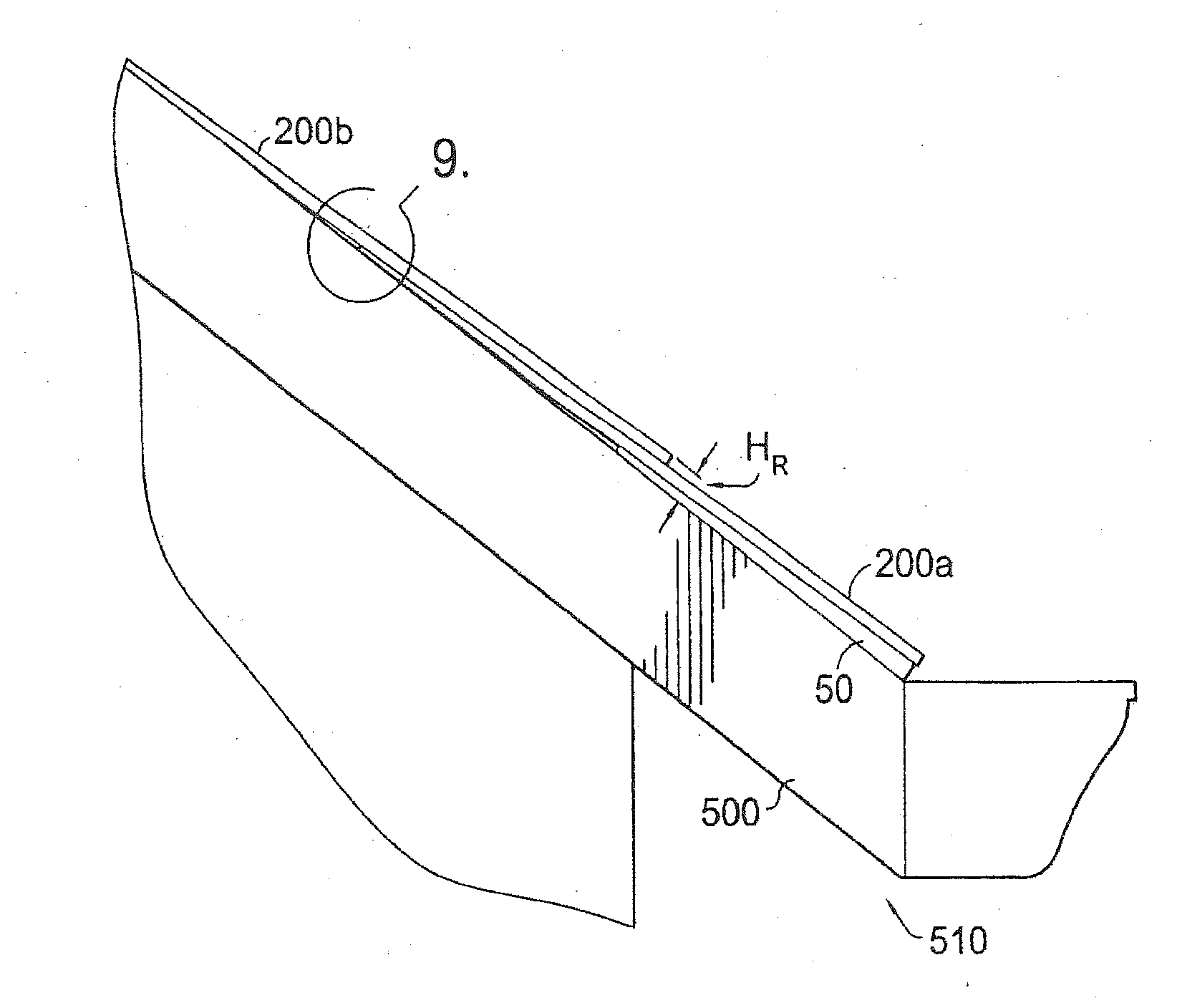

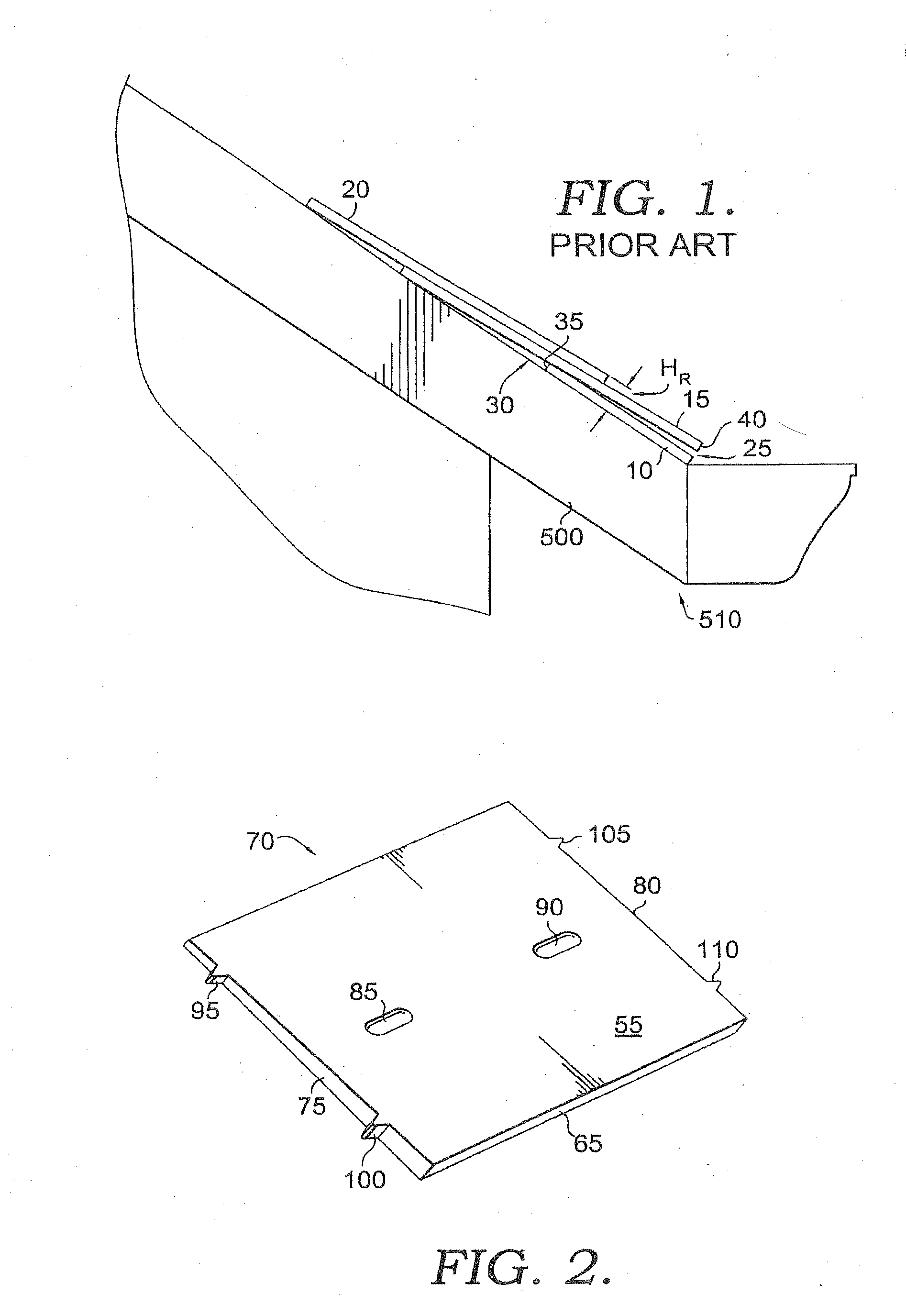

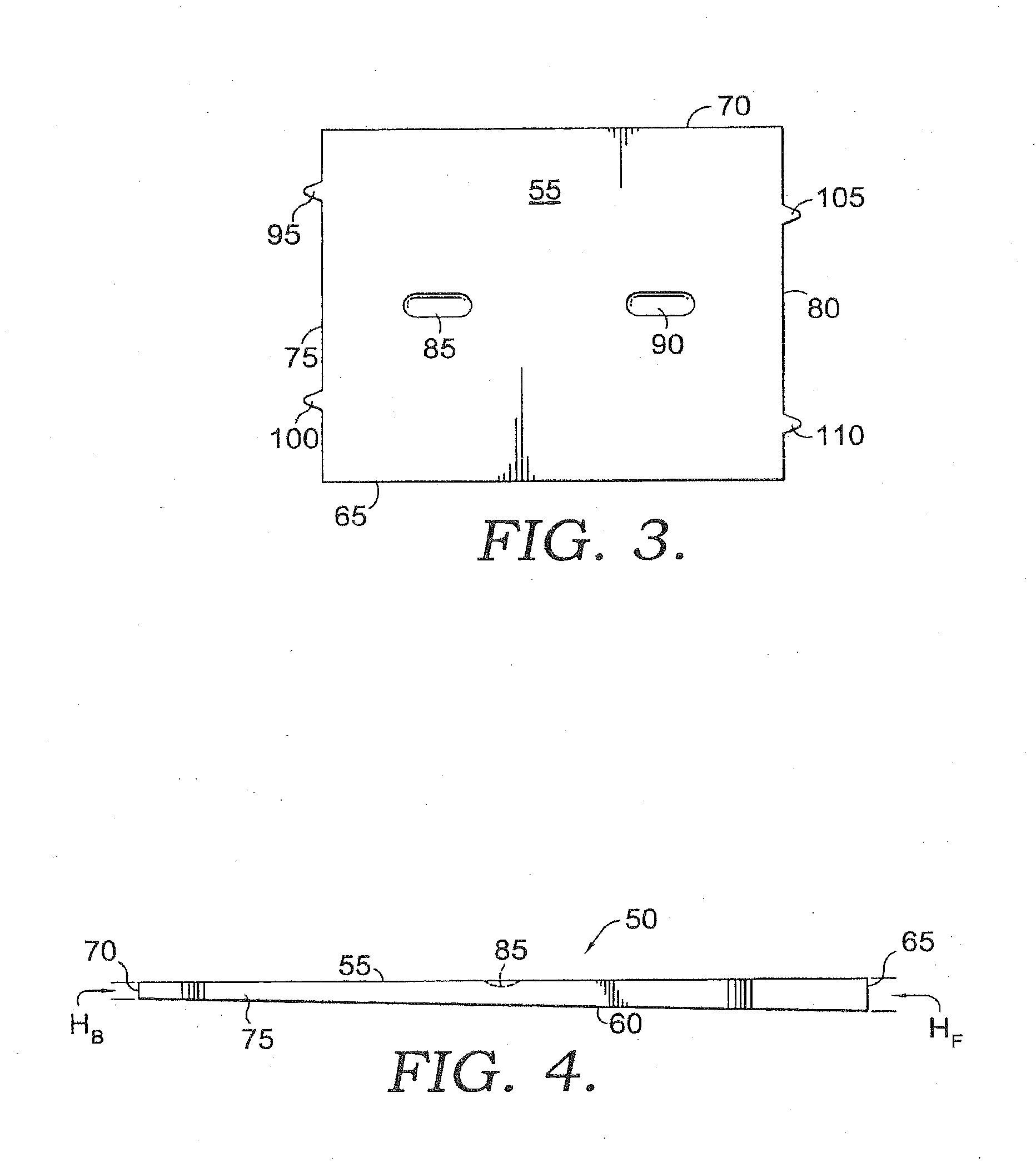

[0026]The present invention provides a starter block and a shingle each designed with a tapered thickness for improving the performance of a roofing system. The starter block is configured for use in the starter course of a roofing project to facilitate the subsequent positioning of shingles on the roof. More specifically, the tapered thickness of the starter block and selective tapering of the shingle thickness allow for shingle installation without substantially bending, stressing or breaking the shingles, while also providing a durable design capable of withstanding strong impact loads from above. The starter block and shingle design preferably incorporate the use of composite materials to enable mass-production and the realization of efficiencies in forming roofing products with a more complex geometry (i.e., with a taper).

[0027]As seen in FIGS. 2, 3 and 4, one embodiment of the starter block of the present invention is generally denominated by the numeral 50. Starter block 50 i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com