Hybrid free-air gas turbine engine

a gas turbine engine and free-air technology, applied in the direction of machines/engines, waterborne vessels, climate sustainability, etc., can solve the problems of high acquisition and operating costs of aviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

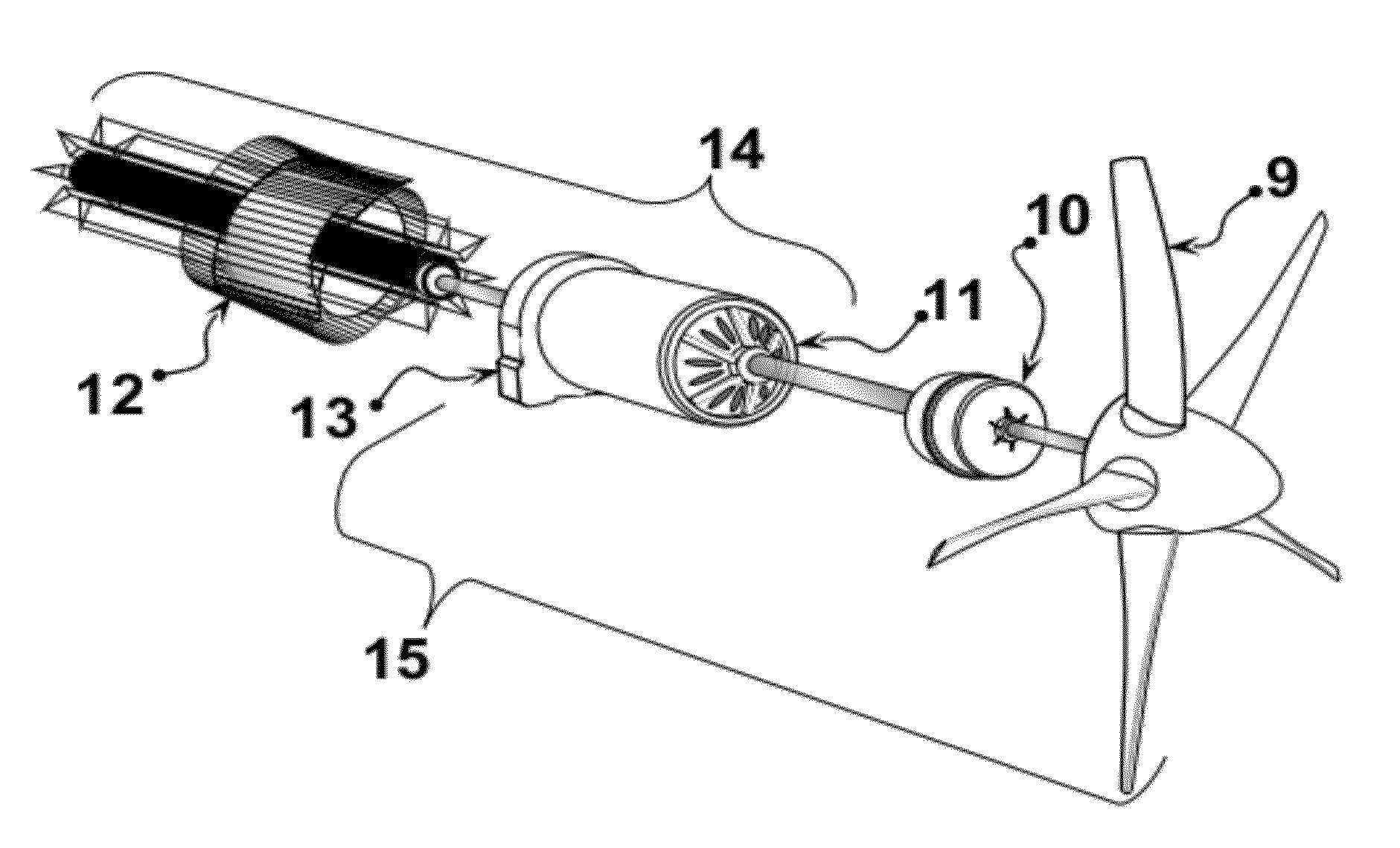

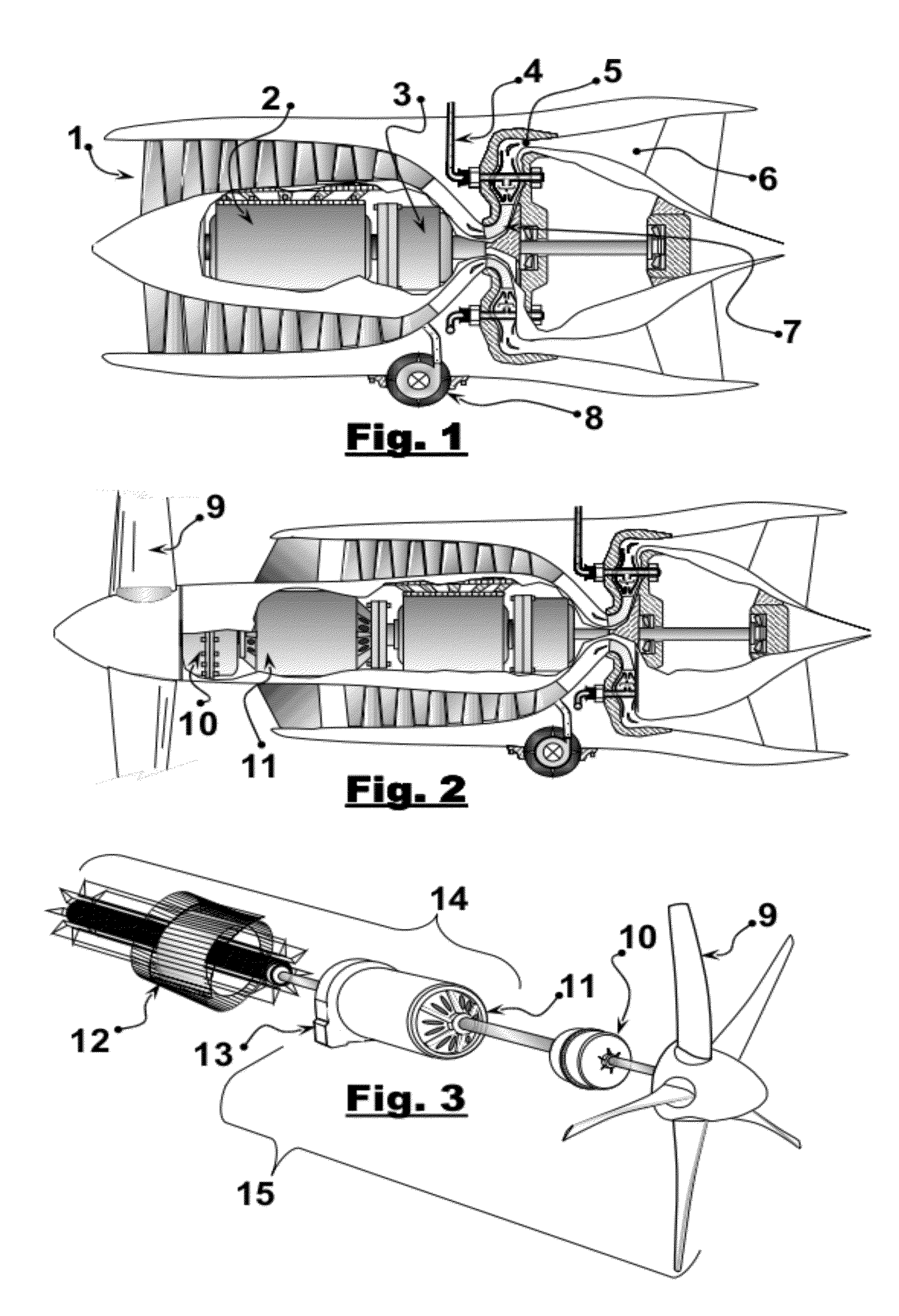

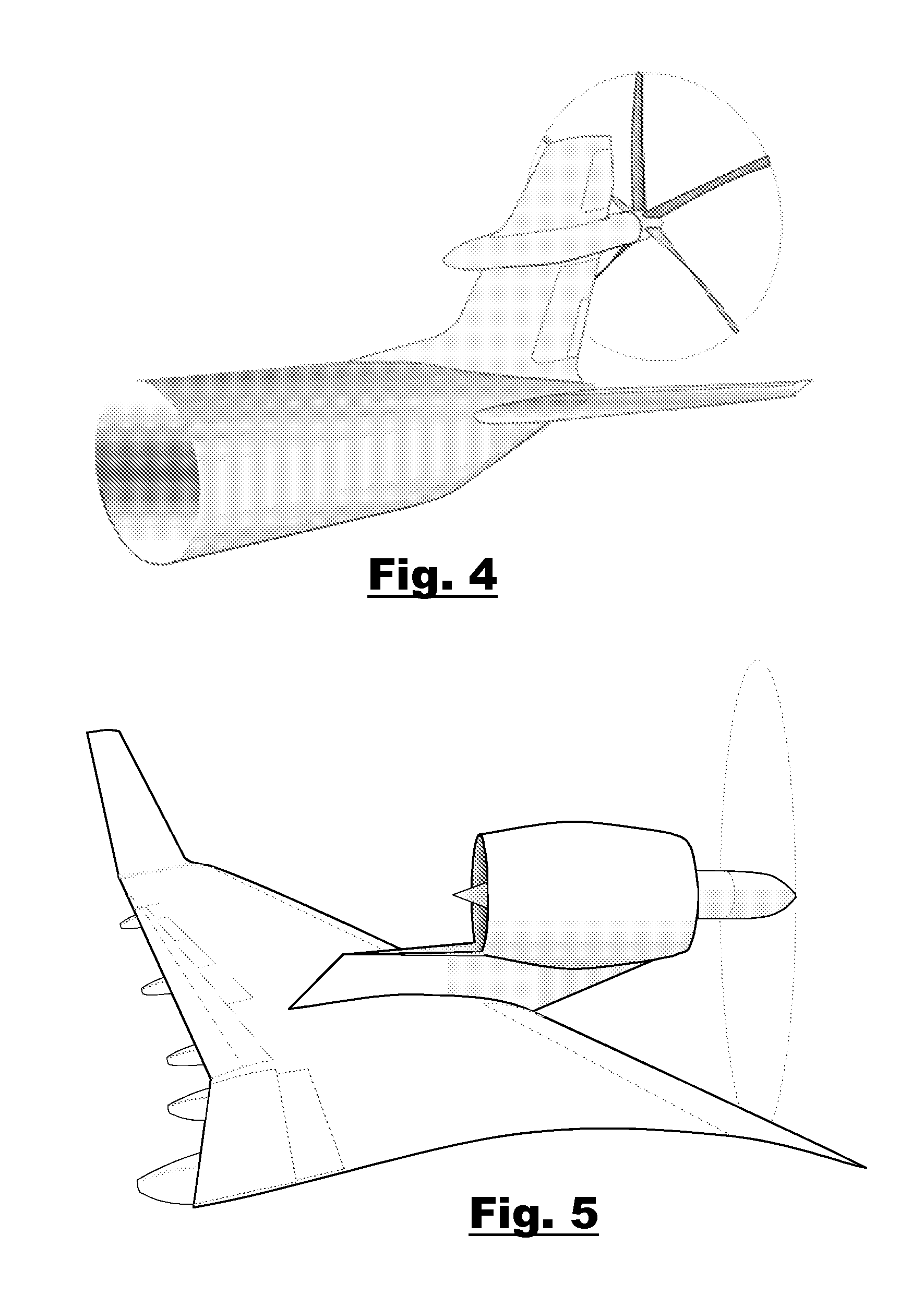

[0039]The invention may be visualized as being composed of three major component modules, where a conventional turbocompressor section using axial and / or centrifugal stages is still present as typical to conventional gas turbine engines.

[0040]In contradiction to conventional design, however, this invention has a compressor section that is not powered by a hot section (gas generator) power turbine mechanically linked to it by a rotating shaft, but is instead powered by one or more high-output electric motors; followed by fuel burners and then an exhaust nozzle. This portion of the engine is referred to as the ‘thrust module’. No advance over prior art is intended in the combustion or the exhaust nozzle, though it will be explained later that combustion section components must be engineered, using established technology, for its stationary parts to accommodate much hotter ignited gas flows.

[0041]The turbocompressor configuration described above needs a source of electrical energy to p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com