Balancing of Wind Turbine Parts

a technology of wind turbines and parts, applied in the direction of engine fuction, color television, television systems, etc., can solve the problems of deteriorating the structure or individual components, significant vibration in the tower, unsafe operation of the turbin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

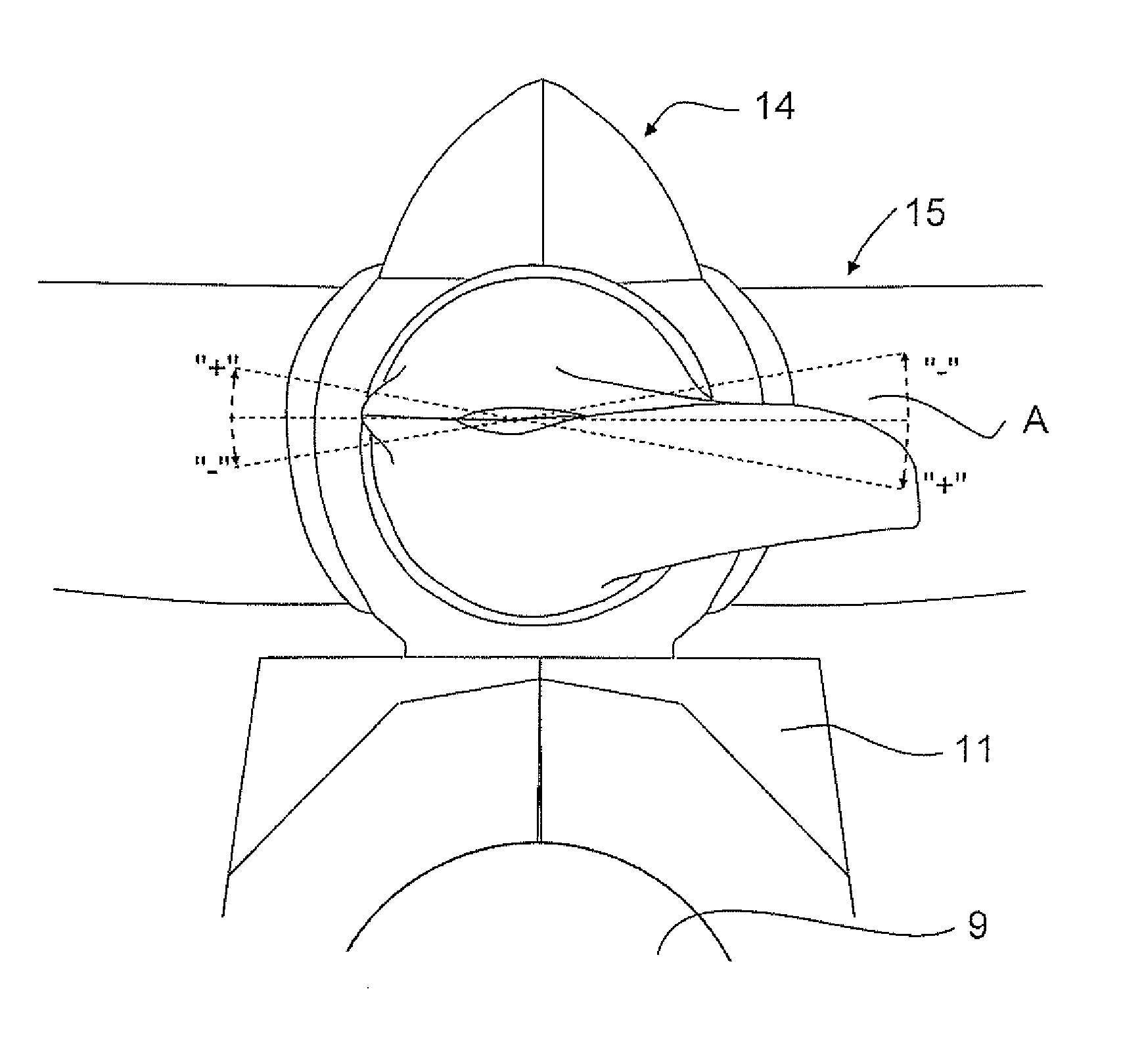

[0082]In FIGS. 7A and 7B is shown a conventional wind turbine. This includes a nacelle 11 mounted on a tower 9 underneath the nacelle. A main shaft 13 connects the drive train to the hub and rotor assembly of the hub body 14 carrying the blades 15 which are typically three blades arranged at 120 degrees. The blades 15 are mounted at fixed angularly spaced positions around the axis. The turbine includes a wind detection and control system 8 which analyses the wind speed and direction repeatedly so as to repeatedly adjust the angle of the nacelle 11 around a vertical axis 9A of the tower, that is the angle of the rotor axis 13 relative to the wind direction, and to adjust the angle A (FIG. 1) of attack of the blades 15 around the longitudinal axis of the blade relative to the wind speed.

[0083]Turning now to FIG. 9, a conventional wind turbine shown including a nacelle 11 mounted on a cylindrical tower underneath the nacelle. A main shaft 13 connects the drive train to the hub and roto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com