Method and system for recycling and treating dyeing wastewater

a technology for applied in water/sewage multi-stage treatment, filtration separation, separation process, etc., can solve the problems of high cost, large amount of sludge, and inability to dehydrate sludge by distillation, etc., and achieve the effect of efficient recycling and treating dyeing wastewater and low cos

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

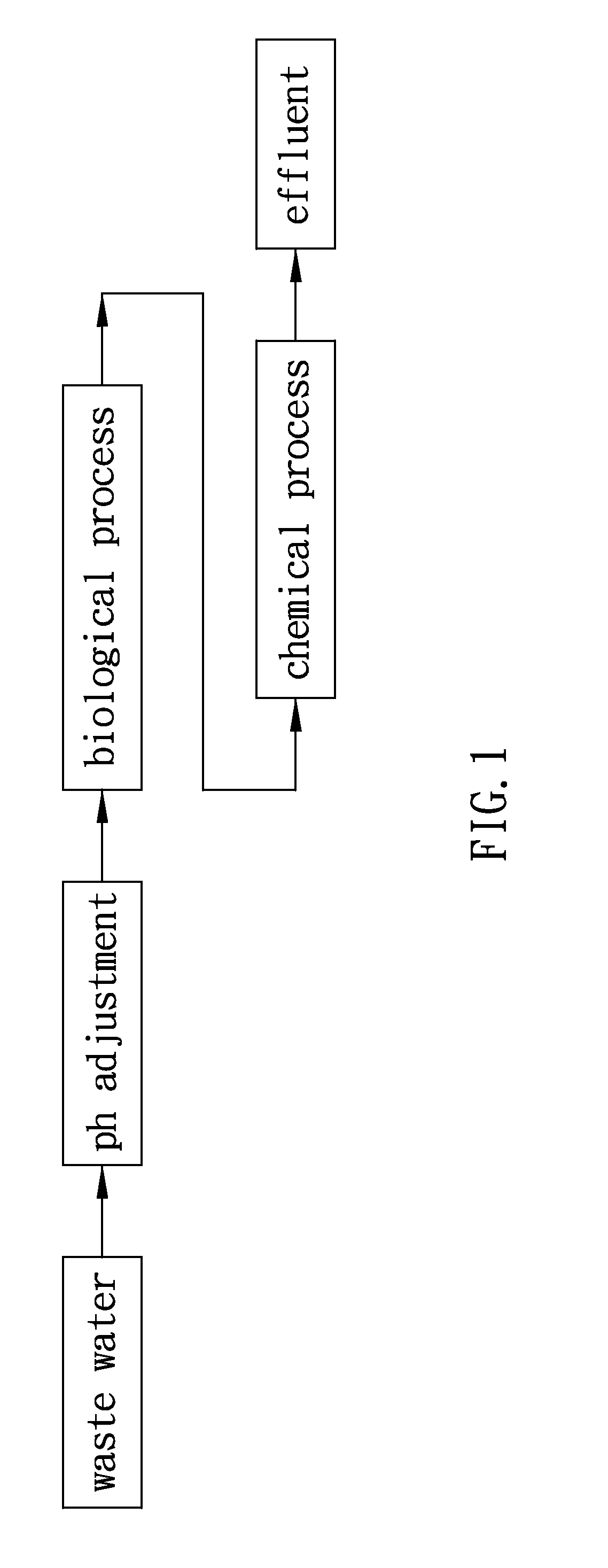

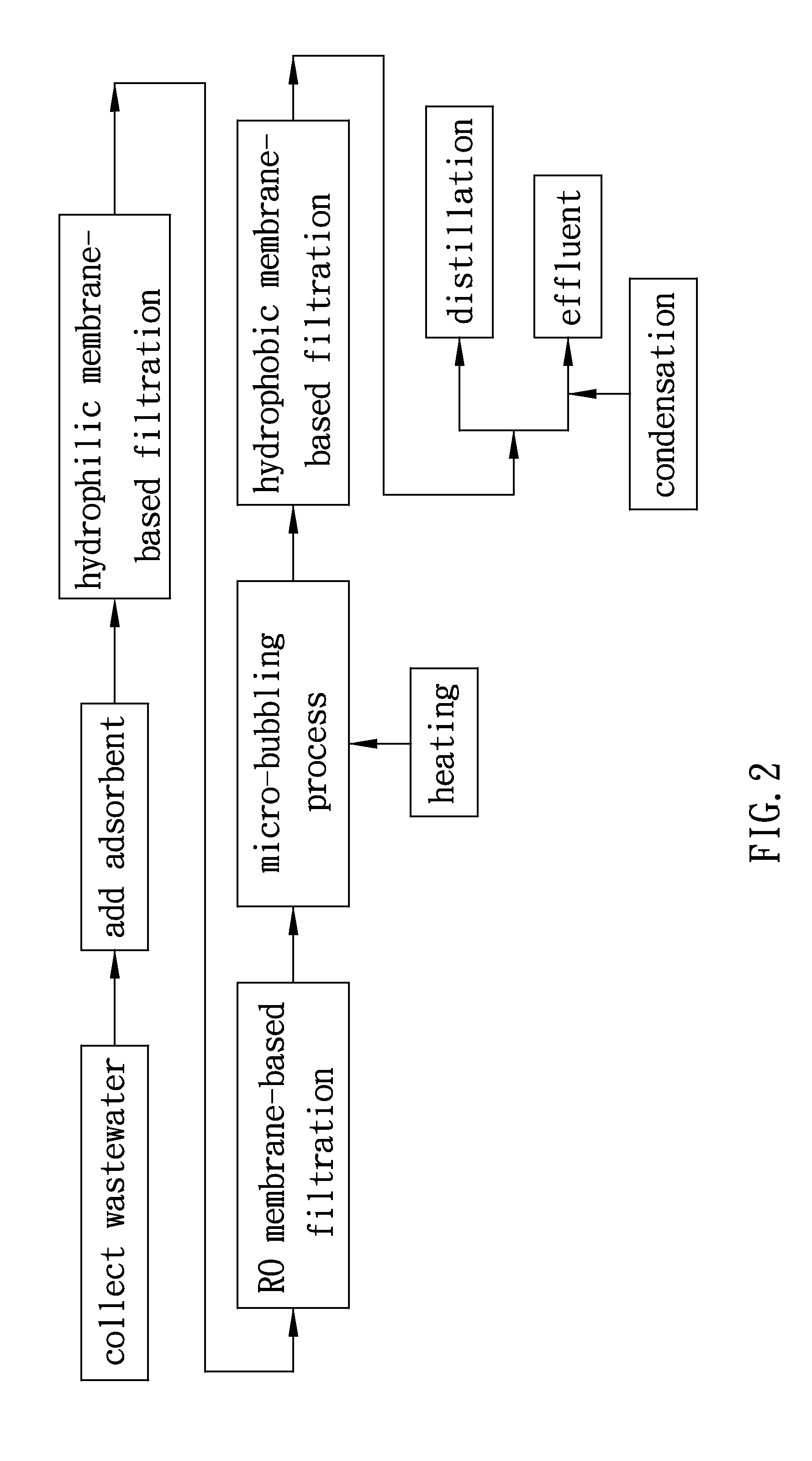

[0025]Please refer to FIG. 2 and FIG. 3 for a method and system for recycling and treating dyeing wastewater according to a first embodiment of the present invention. As shown in FIG. 2, the method comprises the following steps:

[0026]Step (A): Dyeing wastewater is collected and guided into a pre-treatment tank 10 for subsequent treatment.

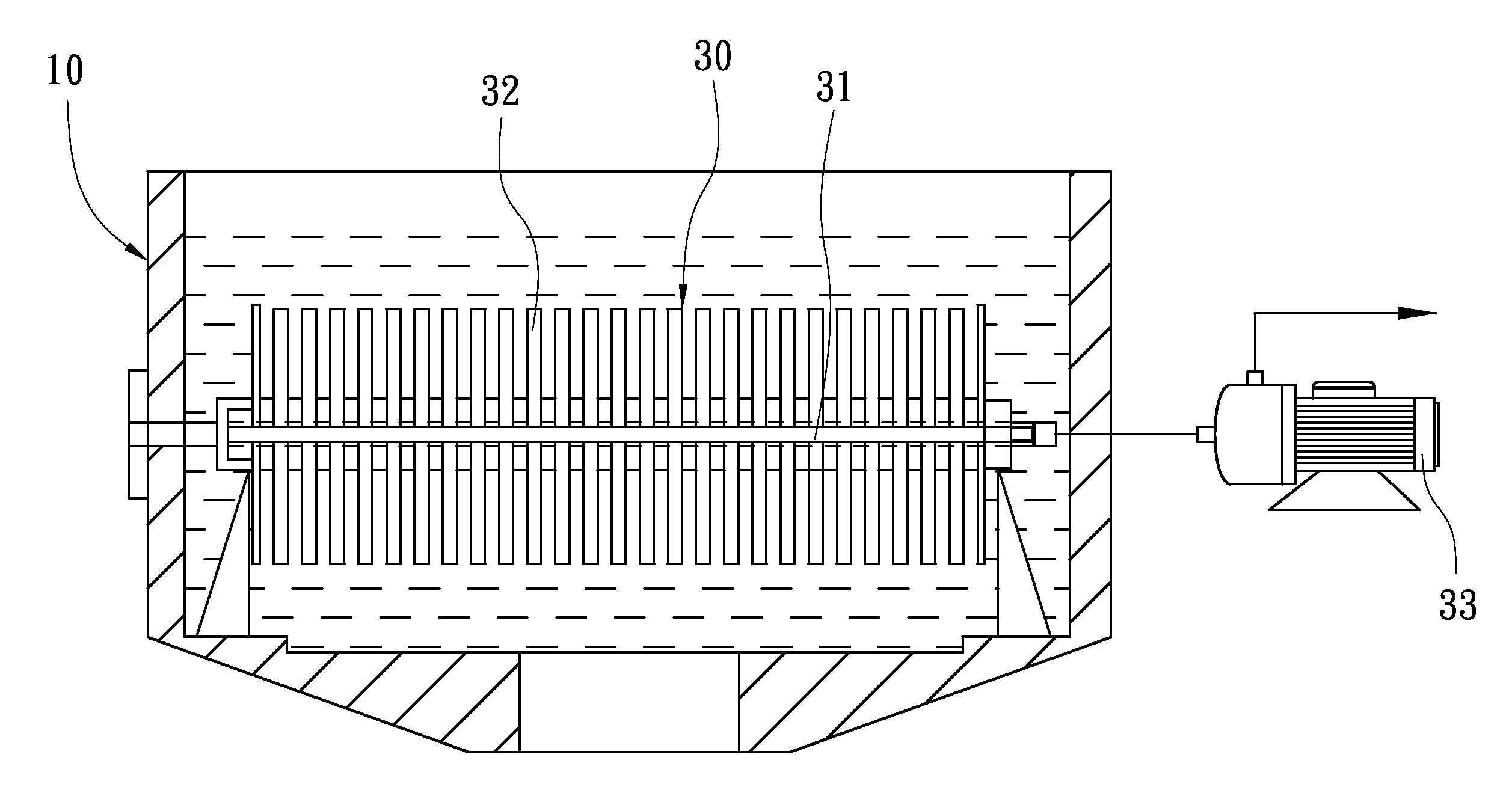

[0027]Step (B): An appropriate amount of adsorbent 20 is added into the pre-treatment tank 10, wherein the adsorbent 20 is one of diatomite, activated carbon, and zeolite powder. The adsorbent 20 is quickly mixed with the dyeing wastewater so as for the adsorbent 20 to adsorb the dyes and suspended particles in the dyeing wastewater and thereby assist in decolorization and filtration of the dyeing wastewater. The pre-treatment tank 10 is provided therein with a first filtration device 30. Referring to FIG. 4, the first filtration device 30 is transversely disposed and submerged in the pre-treatment tank 10. The first filtration device 30 comprises a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com