Nanofiber spectral analysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

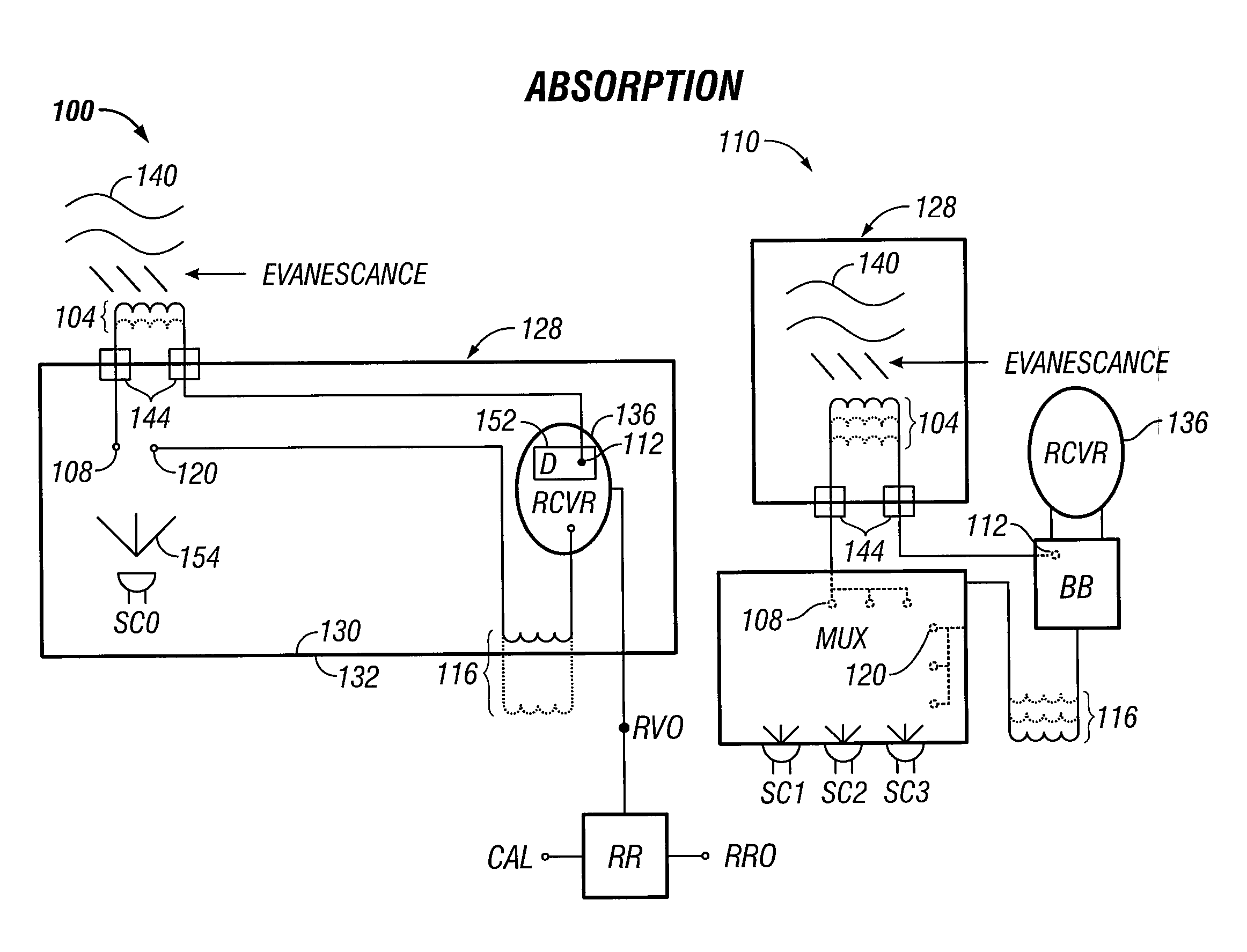

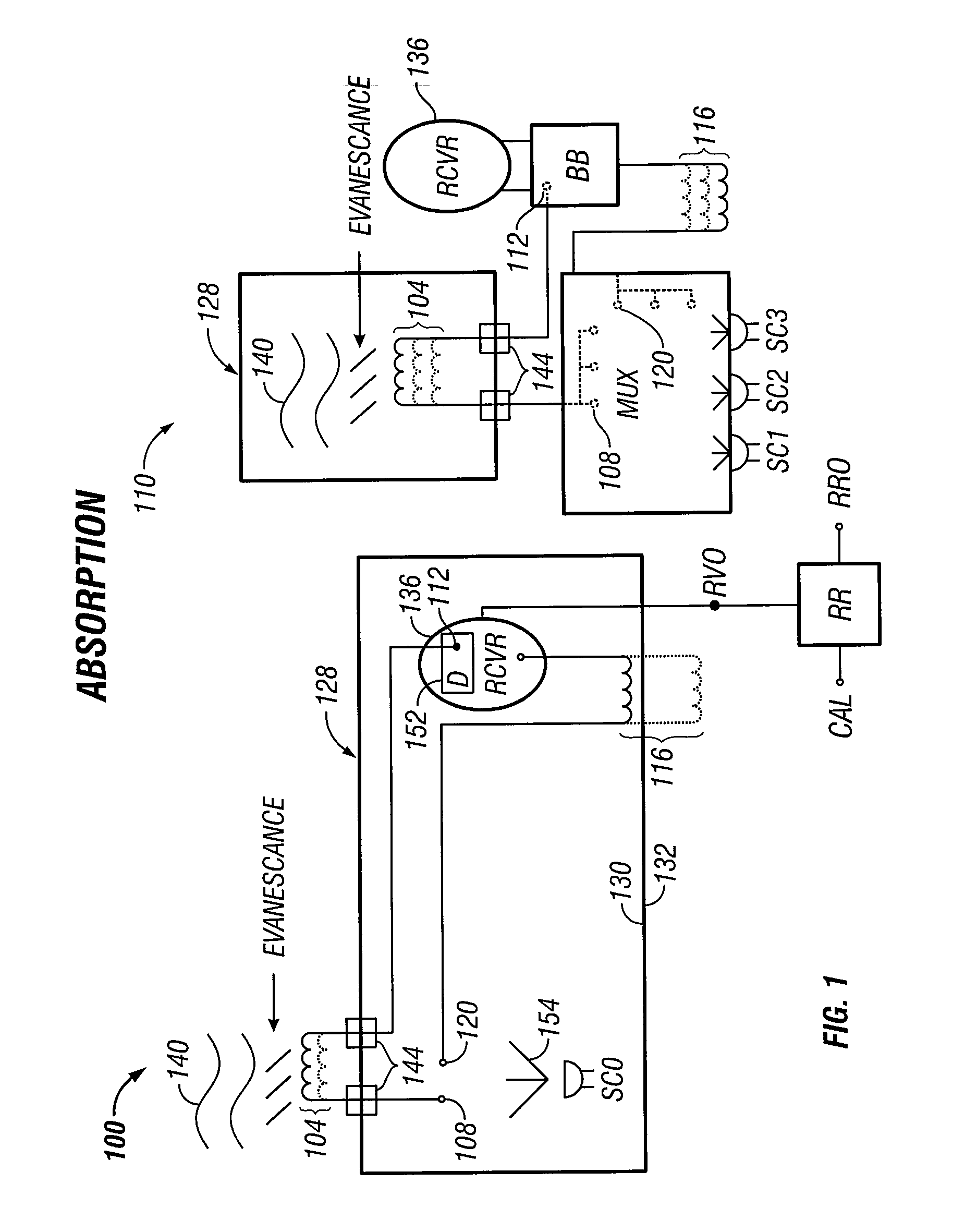

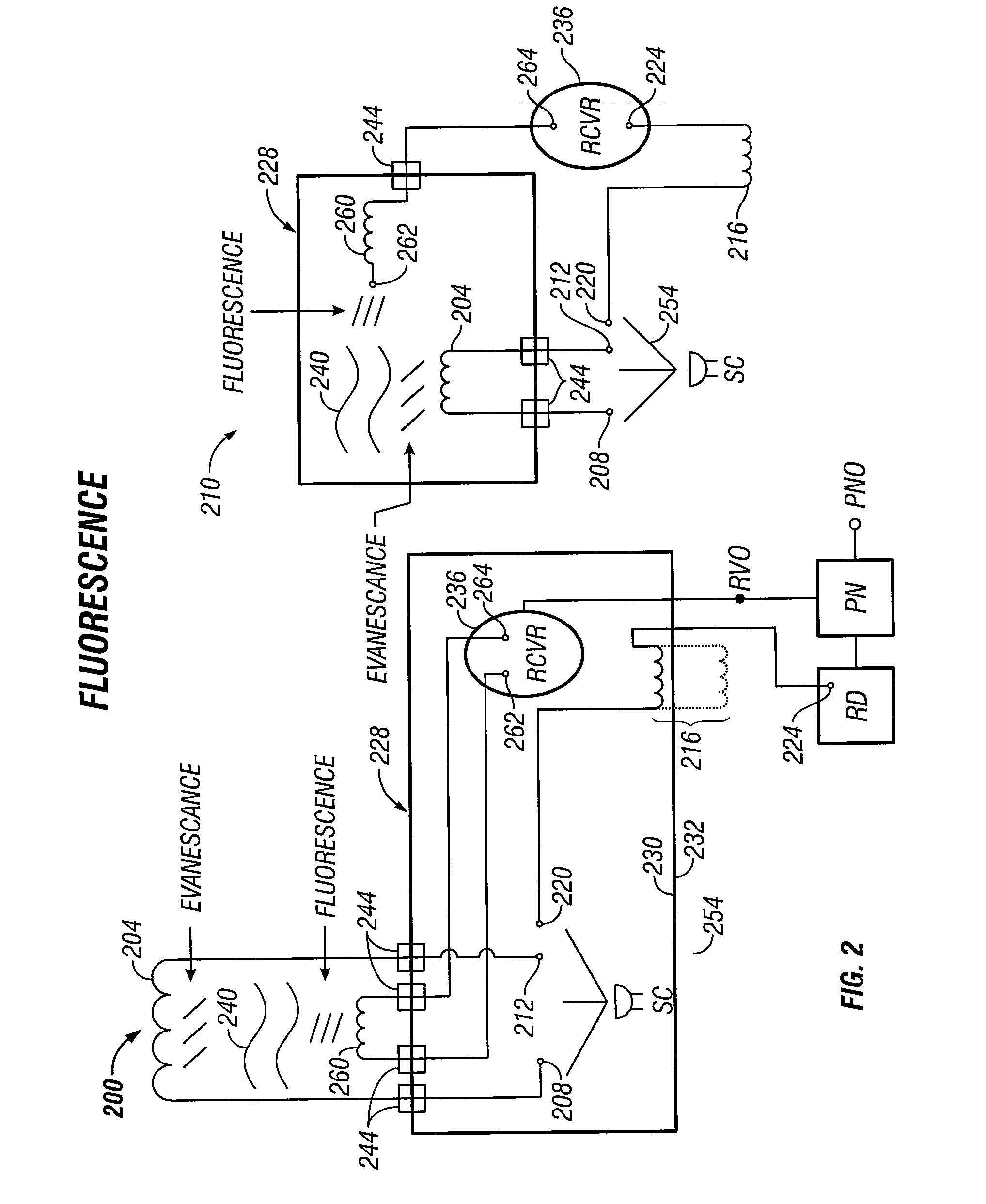

[0011]In most embodiments, nanofibers can be used as part of a spectrographic analysis apparatus to overcome some of the difficulties noted above. This can be useful in downhole environments, where high temperature and pressure can be present. Many other analysis environments can also benefit.

[0012]Evanescent electromagnetic fields are an extension of electromagnetic radiation outside of the medium which carries the electromagnetic radiation. For example, evanescent field production can occur via total internal reflection. This form of evanescent field spectroscopy has been commercialized in the form of attenuated total internal reflection spectroscopy.

[0013]Evanescent fields can also be produced when the reflection of electromagnetic energy occurs at the boundary of materials with different indices of refraction, such as when the index of refraction of the medium that carries the energy is greater than the index of refraction of a material behind the reflective surface. Generally, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com