Method and Fuel Composition for Catalytic Heater

a technology of catalytic heaters and fuel compositions, which is applied in the direction of burners, combustion regulation, combustion types, etc., can solve the problems of inefficient combustion of carbon monoxide byproducts, indirect methods, slow and inefficient heating of catalysts,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

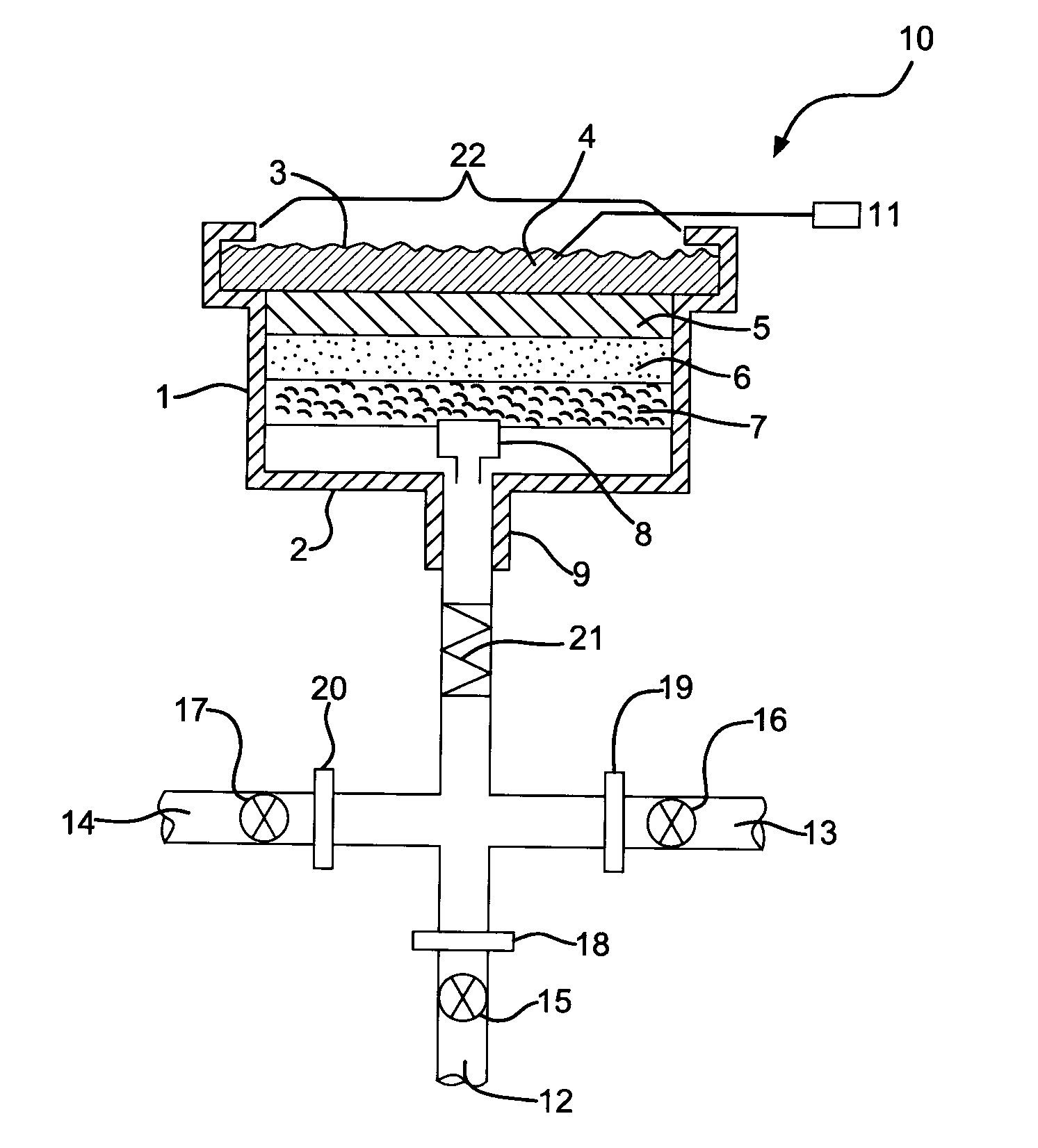

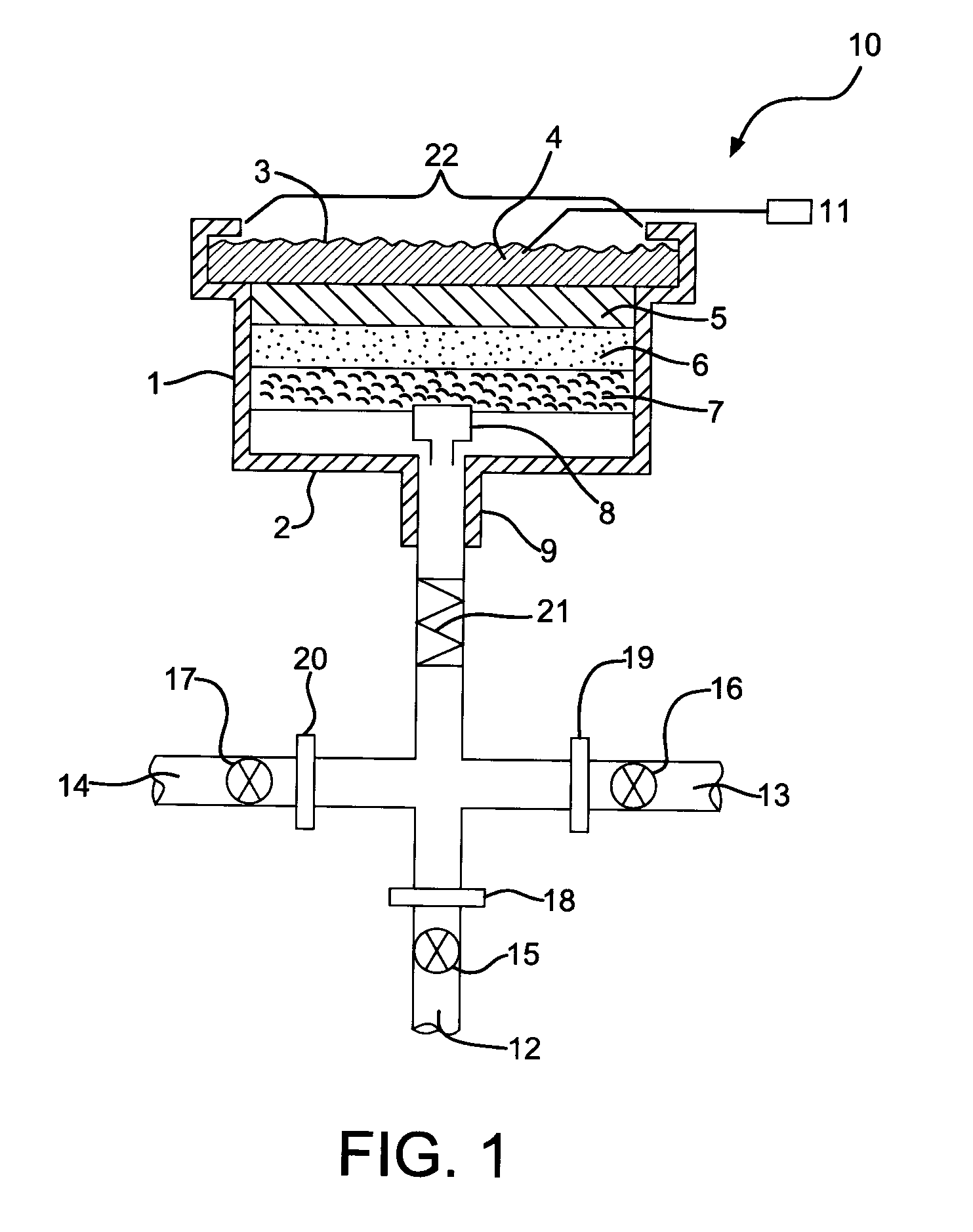

Image

Examples

examples

[0027]The following examples illustrate the ability to use the method and preheat compositions described herein to preheat a typical catalytic heater. A series of tests were conducted whereby the catalytic heater was preheated using different preheat compositions described in Table 1. The tests were conducted using a catalytic heater from Vulcan Catalytic Systems to illustrate the reduced methane slip and the homogeneous surface temperature benefits of the preheat composition and method described herein. The catalytic heater was mounted in a vertical orientation at the center of a ventilated enclosure with a known constant ventilation rate for the purpose of the tests. The vertical mount facilitated capturing images of the heater surface. The catalytic heater inlet was connected to a flow skid that is capable of metering a supply of hydrogen at a certain flow rate or a fuel composition containing one or more of the following components: hydrogen, nitrogen and natural gas at a specif...

examples 1 through 5

[0034]In Example 1, the catalytic heater preheats gas composed of 62% hydrogen and 38% natural gas is supplied to the catalytic heater for two minutes. The hydrogen gas supply is shut off and the natural gas flow is increased to maintain a constant flow of gas through the heater.

[0035]In Example 2, the catalytic heater preheat gas composed of 100% hydrogen is supplied to the catalytic heater for two minutes. The hydrogen gas supply is shut off and the natural gas supply is turned on at a flow rate that maintains a constant flow of gas through the heater.

[0036]In Example 3, the catalytic heater preheat gas composed of 100% hydrogen is supplied to the catalytic heater for three minutes. The hydrogen gas supply is shut off and the natural gas supply is turned on at a flow rate that maintains a constant flow of gas through the heater.

[0037]In Example 4, the catalytic heater preheat gas composed of 100% hydrogen is supplied to the catalytic heater for four minutes. The hydrogen gas suppl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com