Transparentization agent composition containing sorbitol compound and method for producing polypropylene resin composition using this sorbitol compound

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

synthesis example

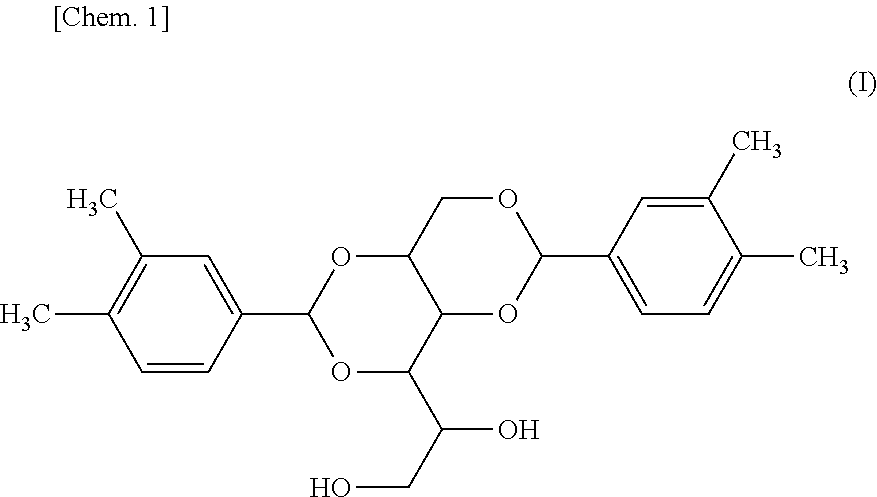

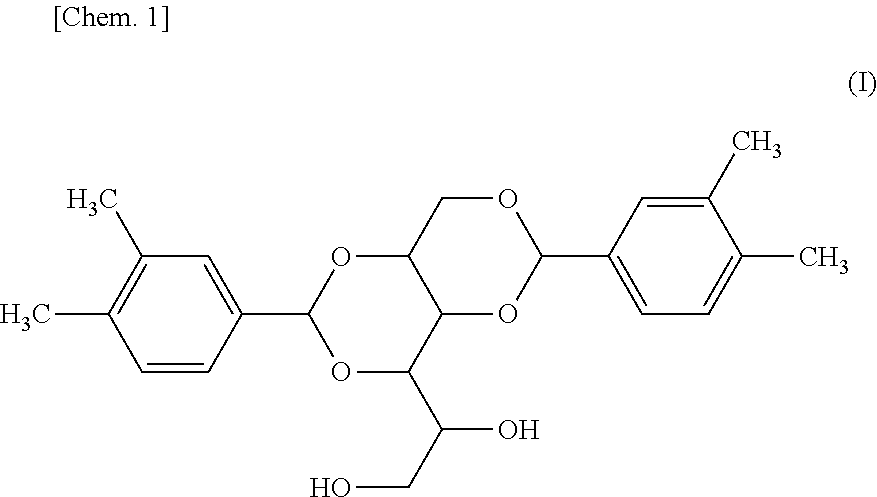

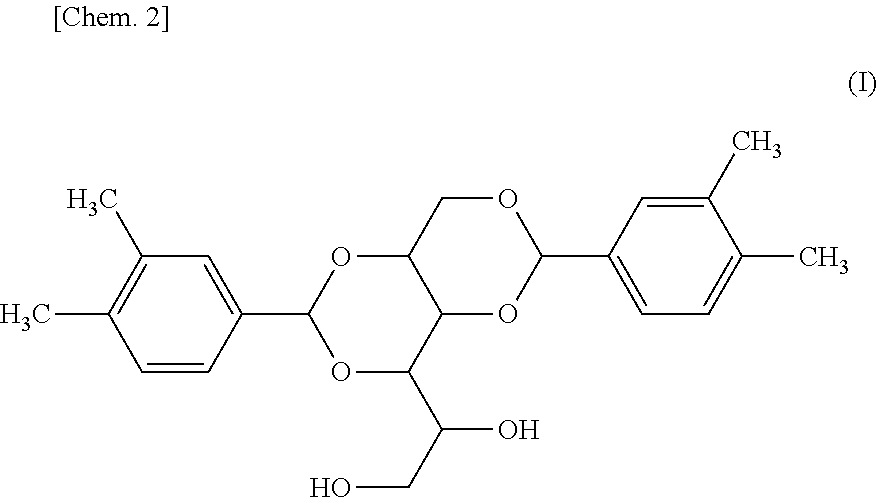

Synthesis of the Dibenzylidene Sorbitol Compound Represented by the General Formula (I)

[0049]To a four-necked reaction flask are added 44 g (0.42 mol) of 3,4-dimethylbenzaldehyde, 38 g (0.21 mol) of sorbitol, 5 g of 50% sulfuric acid as a catalyst, 700 ml of cyclohexane as a solvent and 70 ml of methanol, and stirring is conducted at the reflux temperature of methanol. Methanol of a similar amount to the amount of the volatilized methanol is added dropwise as needed, and a massive substance is obtained by a reaction for 5 hours.

[0050]The obtained massive substance is washed with isopropyl alcohol / water=1 / 1 (volume ratio), and the filtered substance is dried at 90° C. under a reduced pressure.

[0051]The obtained mass was pulverized by a pulverizer to give each dibenzylidene sorbitol powder (it is abbreviated as Sorbitol in Table 1 and Table 2) having d97 described in Table 1 and Table 2. The d97 of the dibenzylidene sorbitol powder was measured by laser light scattering. Furthermore, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Percent by mass | aaaaa | aaaaa |

| Percent by mass | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com