Cooling device

a cooling device and cooling technology, applied in indirect heat exchangers, lighting and heating apparatus, heat exchange apparatus, etc., can solve the problem of further affecting the function of the cooling device in the transportation of working fluid, which is required for the cooling device to be deactivated, and achieves spectacular improvement of capillary attraction, the effect of improving the performance of the cooling device and maximizing the capillary attraction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

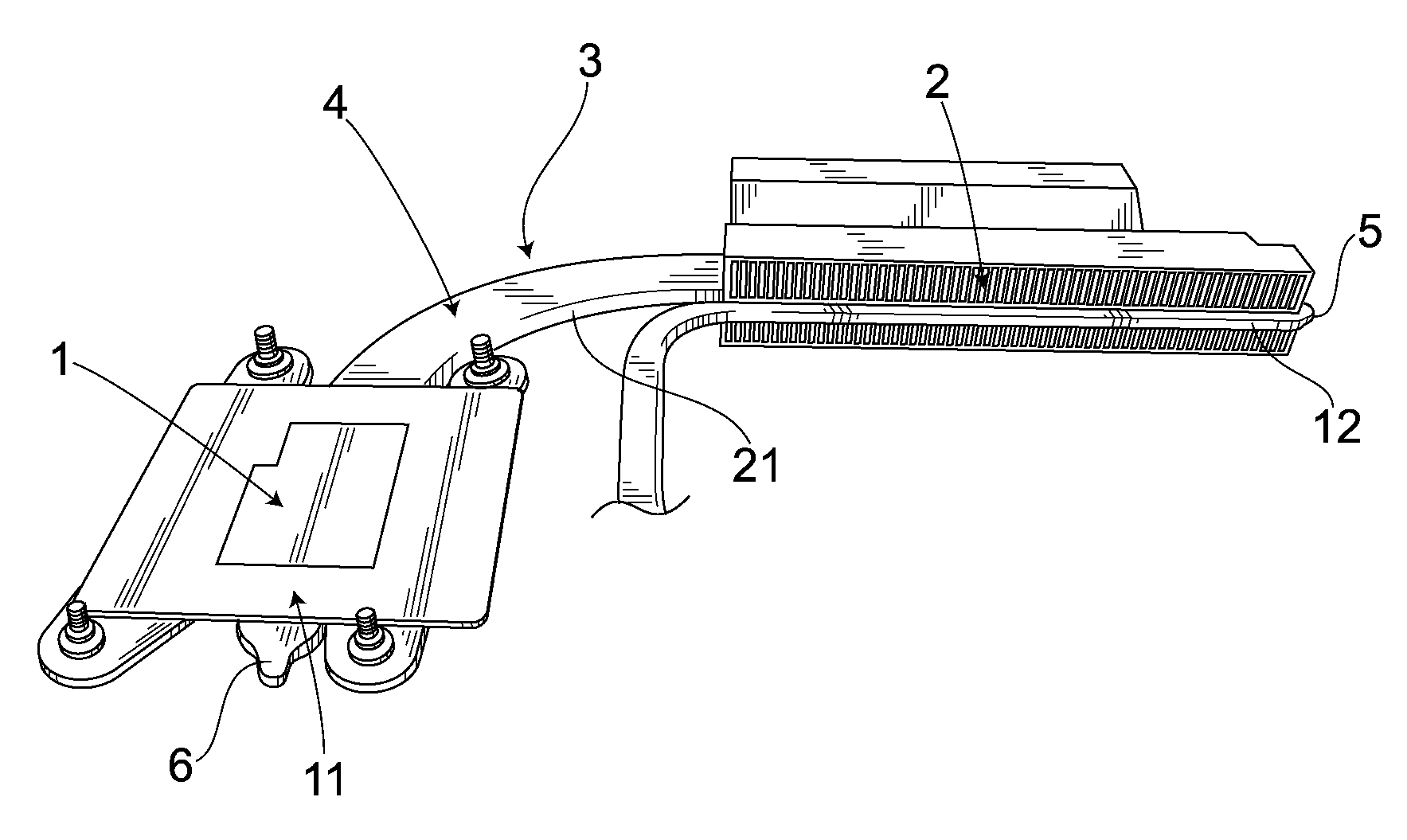

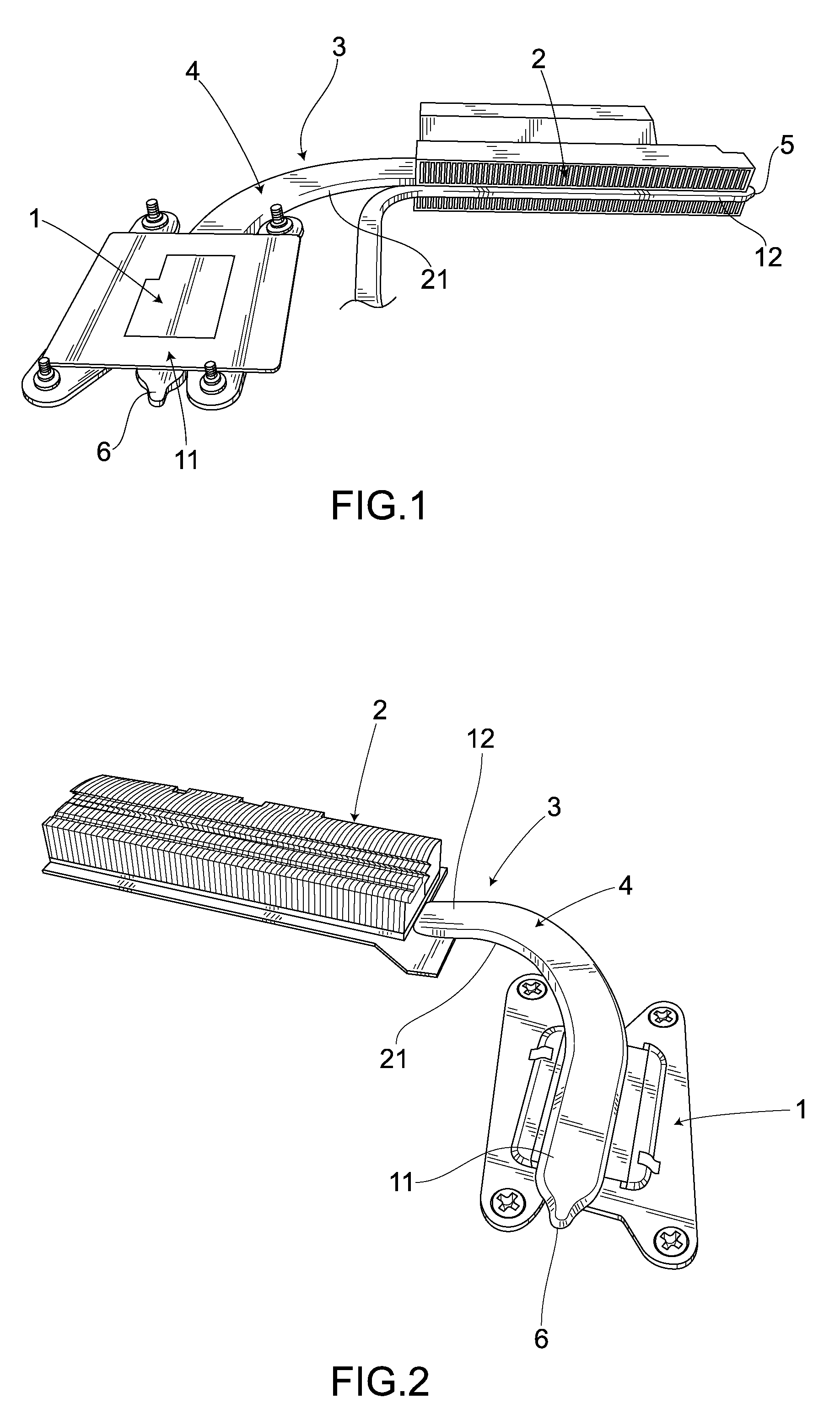

first embodiment

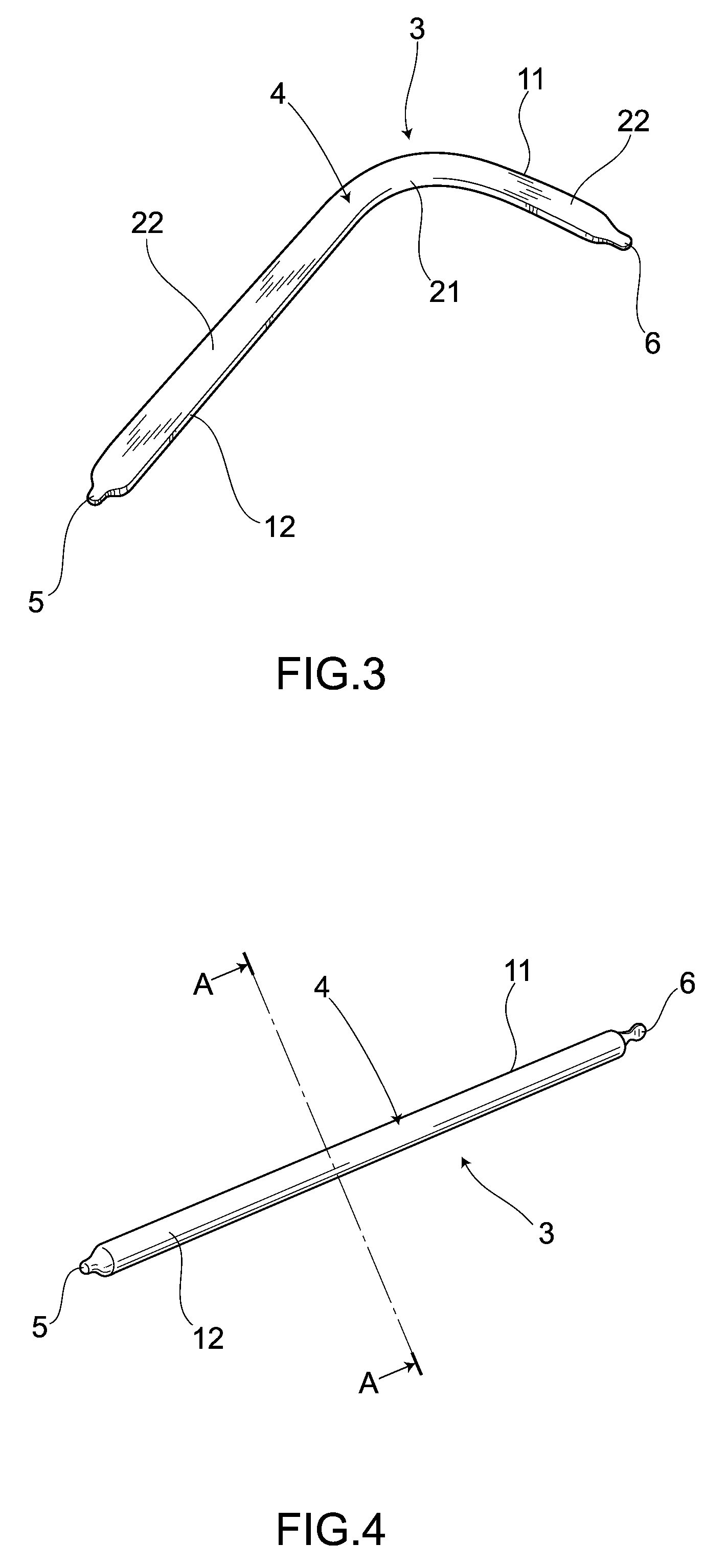

[0063]FIG. 5 to FIG. 10 show heat sink unit according to the present invention. Specifically, FIG. 5 shows a cross-sectional view orthogonal to the longitudinal direction of the heat pipe 3 shown in FIG. 4. In FIG. 5, the inner wall of the container 4, shown here, is formed into a smooth curved surface 16 without irregularities and the copper fiber assembly 8 acting as a fiber assembly with a wicked structure is hermetically housed inside the heat pipe 3 so as to be attached closely to the curved surface 16. The copper fiber assembly 8 is uniformly mounted without a break in mid-course from one end of the heat pipe 3 to the other end thereof. Then, inside the heat pipe 3, there are provided a first flow path 17 formed inside the copper fiber assembly 8 to transfer purified water (not shown), acting as a working fluid condensed in the heat dissipating section 12, toward the heat receiving section 11, and a second flow path 18 formed in a region surrounded by the copper fiber assembl...

second embodiment

[0096]In this embodiment, the inner structure of the heat pipe 3 is different from that in the Specifically, as shown in FIG. 14, as a substitute for the tube 10 produced by weaving the copper fibers 28, a sheet 30 is employed onto which the copper fibers 28 are sintered. The copper fibers 28 employed here are mounted on the inside of the container 4 of the heat pipe 3 so as to be attached closely to the insides of the grooves 19.

[0097]In FIG. 15 and FIG. 16, both show a structure of a single sheet 30 housed inside the heat pipe 3. The sheet 30 is produced by processing a plurality of copper fibers 28 unidirectionally-aligned in layers into a sheet using a sintering process. In order to enhance the capillary attraction of the copper fibers 28, the sheet 30 is arranged so that the copper fibers 28 are unidirectionally arranged along the longitudinal direction of the heat pipe 3.

[0098]In order to manufacture the heat pipe 3 as shown in FIG. 14, firstly, the sheet 30 is rolled up into...

third embodiment

[0131]In addition, the present invention is not limited to the above embodiments and various modifications are possible without departing from the gist of the present invention. The cooling device shown in each embodiment, e.g., can be incorporated in other various devices requiring a cooling operation than a personal computer. Further, a working fluid different from the purified water can be housed and sealed inside the heat pipe 3. Furthermore, in common with each embodiment, considering, as a condition for the heat pipe 3, the large thermal conductivity for thermal transportation, the corrosion resistance to sealed water, hydrophilicity, the adequacy for a sintering process, and the formation of the pipe and the fiber using the same material, copper is the best for the materials of the heat pipe 3, the copper fiber assembly 8, the tube 10, the sheet 30, the unwoven fabric 42, and the sintered sheet 43. Other metals than copper such as aluminum, SUS (stainless steel) or the like, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com