Chip type laminated capacitor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

experimental example

[0107]The laminated ceramic capacitor according to Examples of the present invention and Comparative Examples was manufactured.

[0108]The plurality of ceramic green sheets manufactured to have a thickness of 3.9 μm by applying and drying the slurries formed including the powder such as barium titanate (BaTiO3), and the like, to the carrier film was prepared.

[0109]Next, the inner electrode was formed by applying the conductive paste for the nickel inner electrode to the ceramic green sheet using the screen for forming the patterns of which the margins are asymmetric on the ceramic green sheet.

[0110]The ceramic green sheets were laminated in 370 layers and the laminate was subjected to the isostatic pressing under the pressure condition of 1000 kgf / cm at 85° C. The pressed ceramic laminate was cut in an individual chip form and the cut chip was subjected to a debinder while being maintained at 230° C. for 60 hours under the atmosphere.

[0111]Thereafter, the ceramic laminate was fired in...

modified example

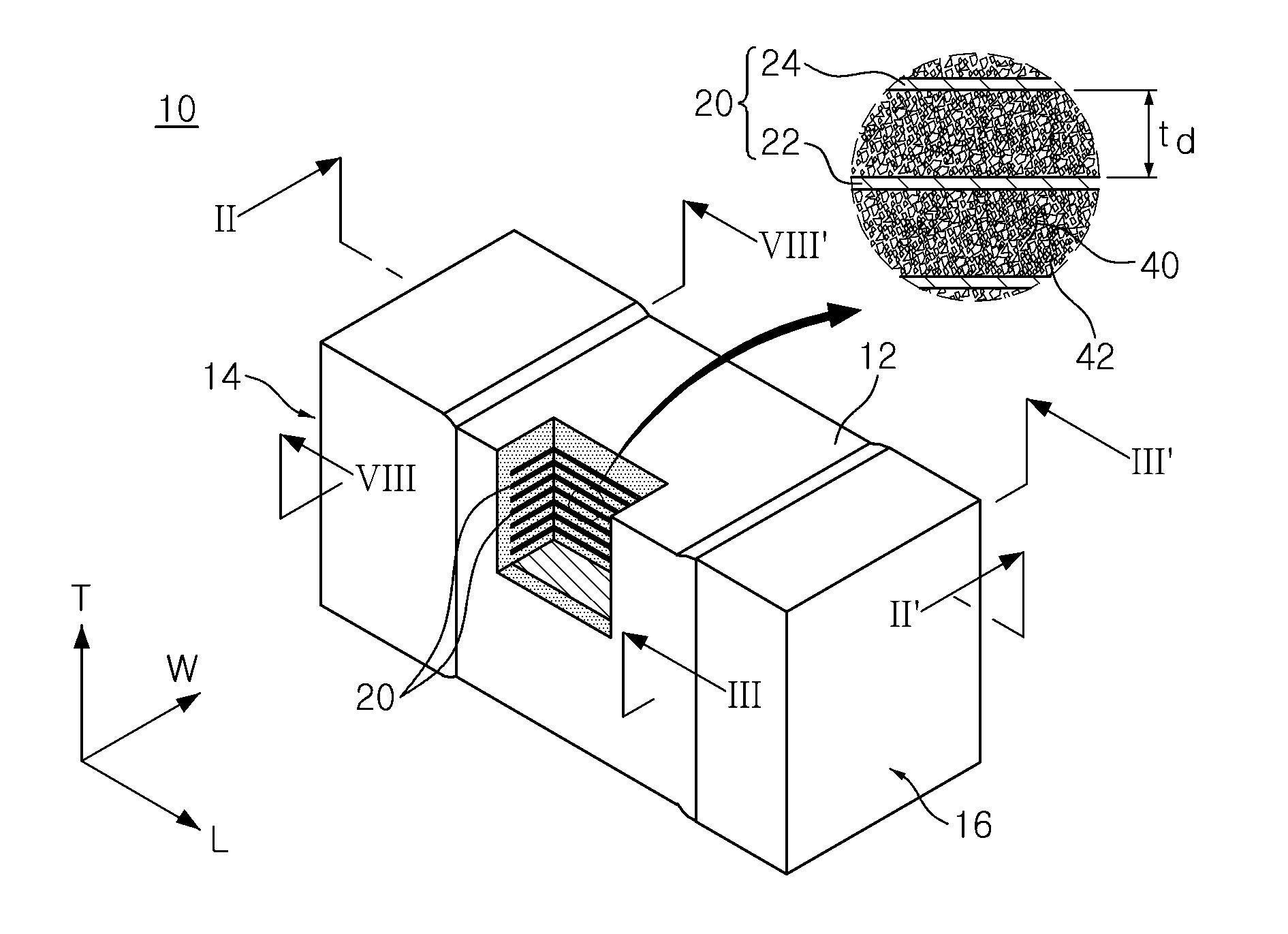

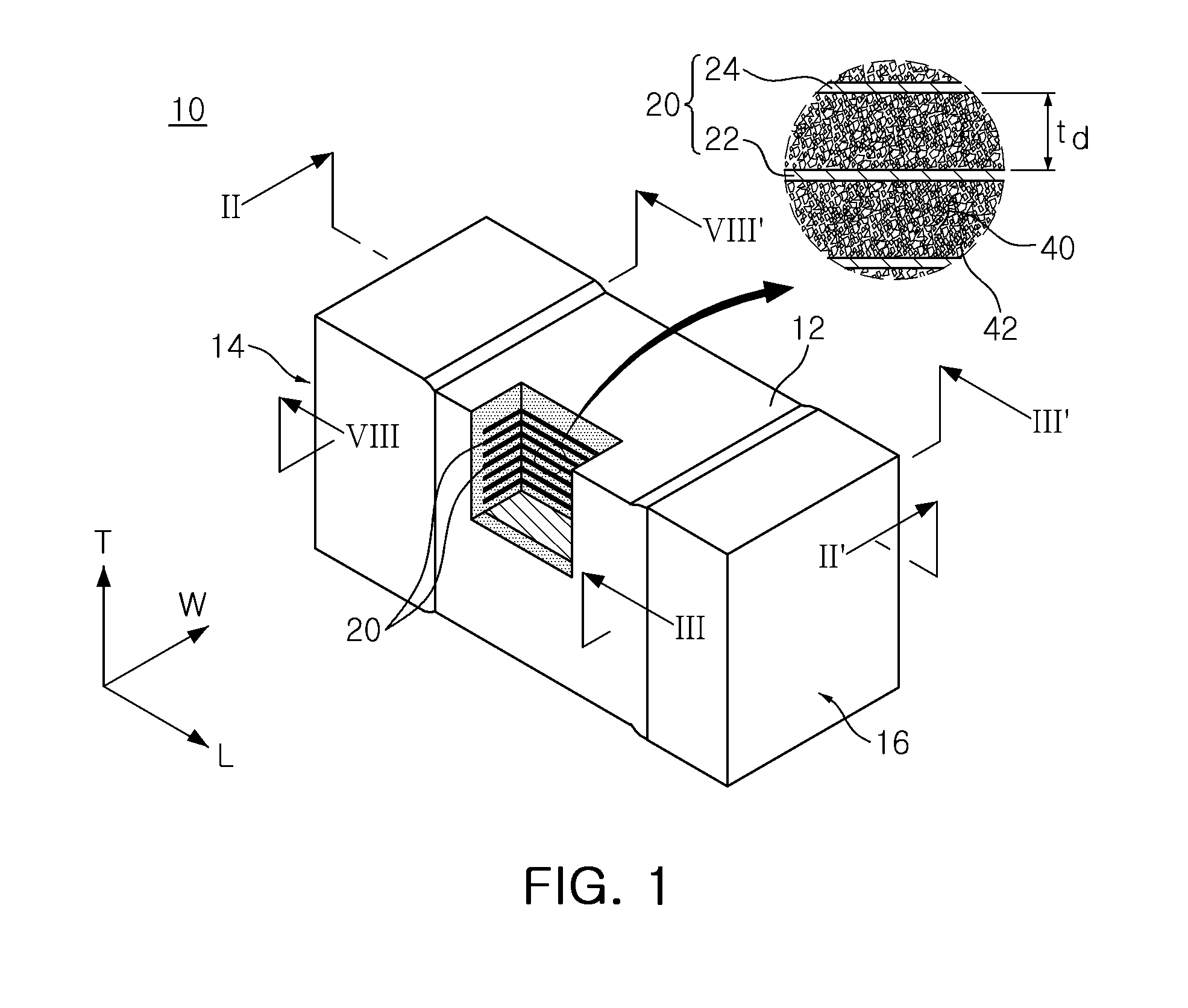

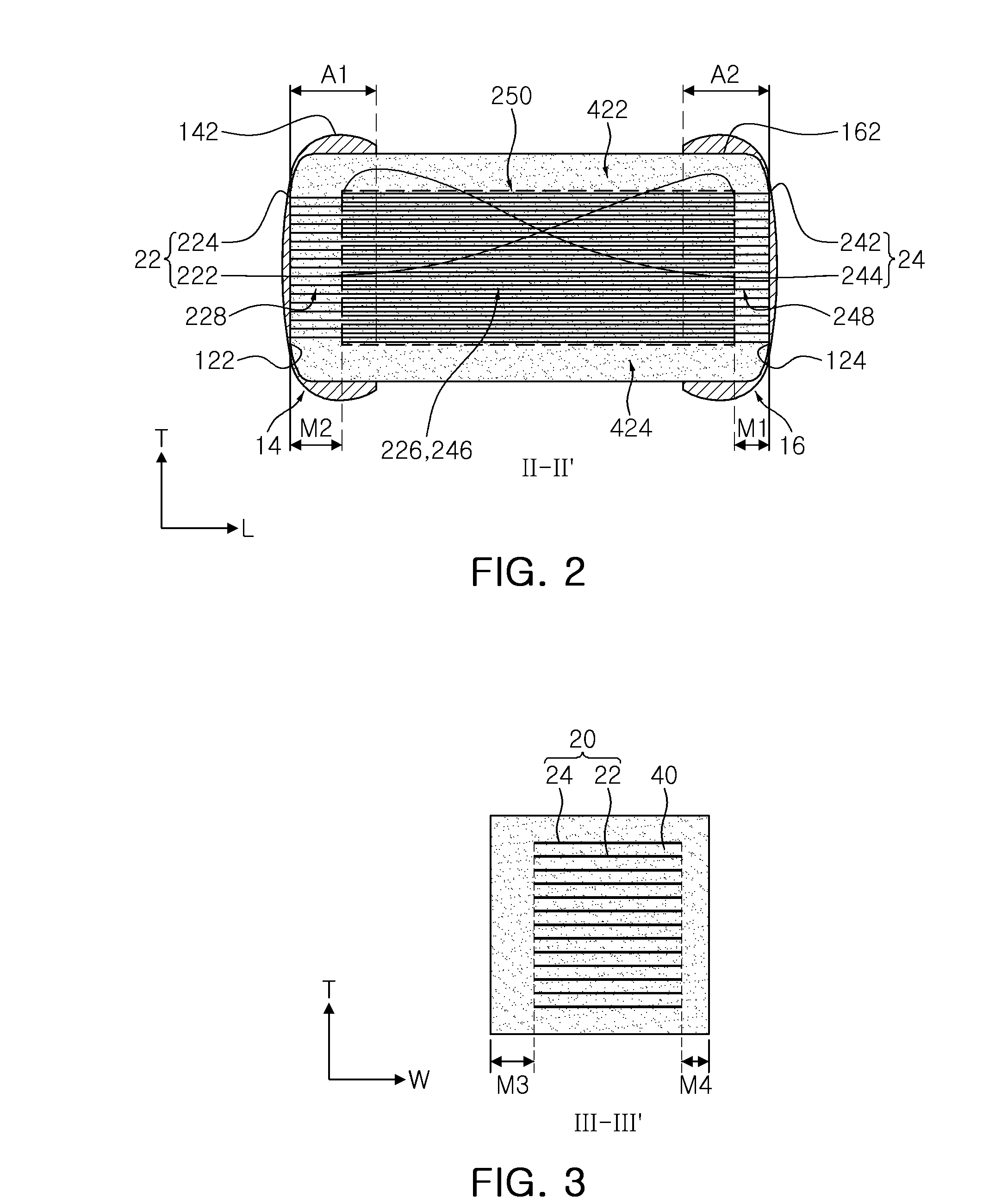

[0128]FIG. 5 is a plan view schematically showing a first embodiment of a shape in which inner electrodes formed on a dielectric layer are laminated and FIG. 8 is a cross-sectional view taken in direction W-T of a shape in which inner electrodes of FIG. 5 are led and is a cross-sectional view taken along line VIII-VIII′ of FIG. 1, where outer electrodes are removed.

[0129]FIG. 6 is a plan view schematically showing a second embodiment of a shape in which inner electrodes formed on a dielectric layer are laminated and FIG. 9 is a cross-sectional view taken in direction W-T of a shape in which the inner electrodes of FIG. 6 are led and is a cross-sectional view taken along line VIII-VIII′ of FIG. 1, where outer electrodes are removed.

[0130]In addition, FIG. 7 is a plan view schematically showing a third embodiment of a shape in which inner electrodes formed on a dielectric layer are laminated and FIG. 10 is a cross-sectional view taken in direction W-T of a shape in which the inner ele...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com