Remote confined-space machining, and positioning and securing arrangement

a technology for confined space machining and positioning, which is applied in the direction of manufacturing tools, mechanical equipment, rod connections, etc., can solve the problems of confined space, the problem of traversing the machining tool relative to the workpiece, and the mounting of the workpiece, etc., and achieves the effect of compact tool arrangemen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

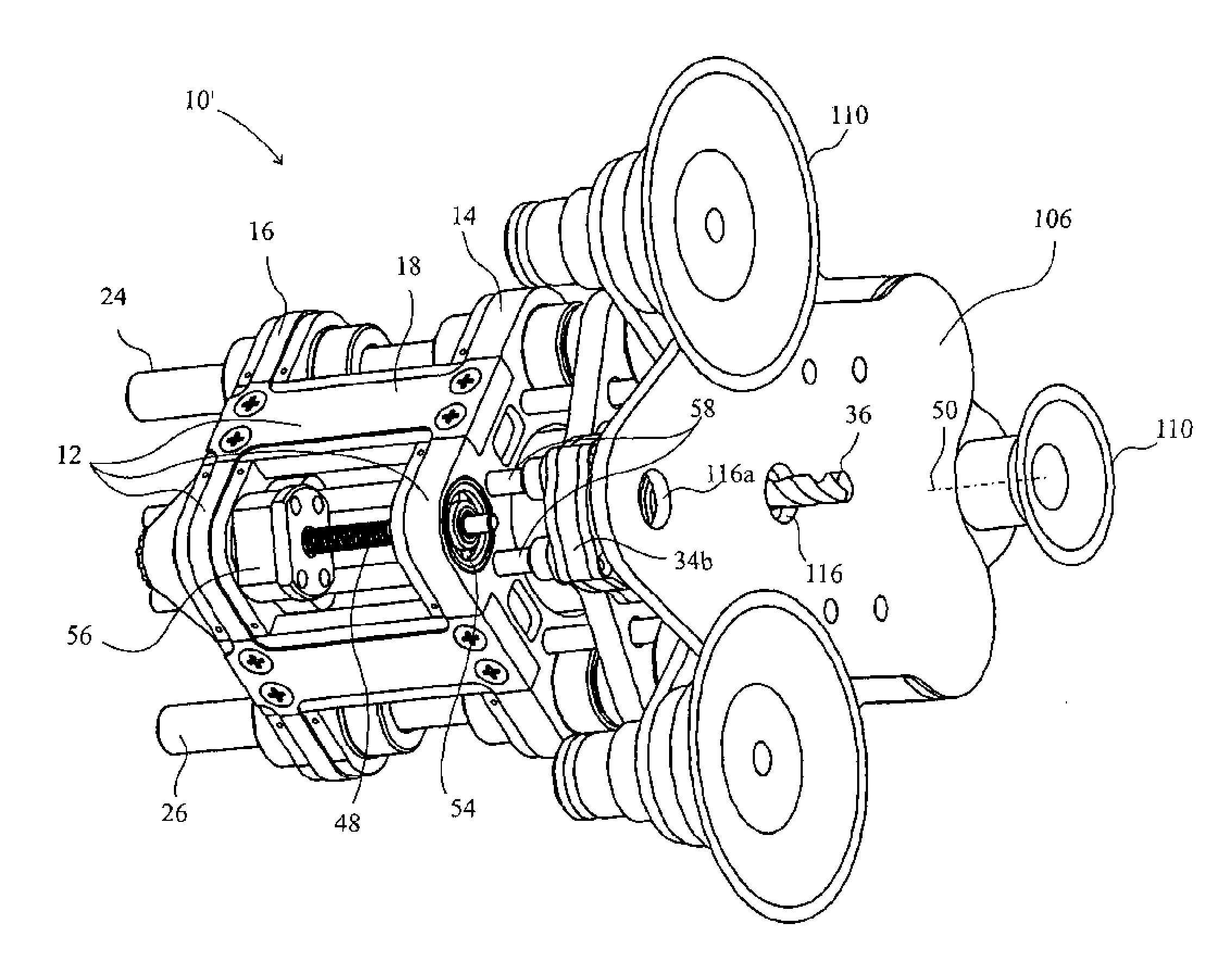

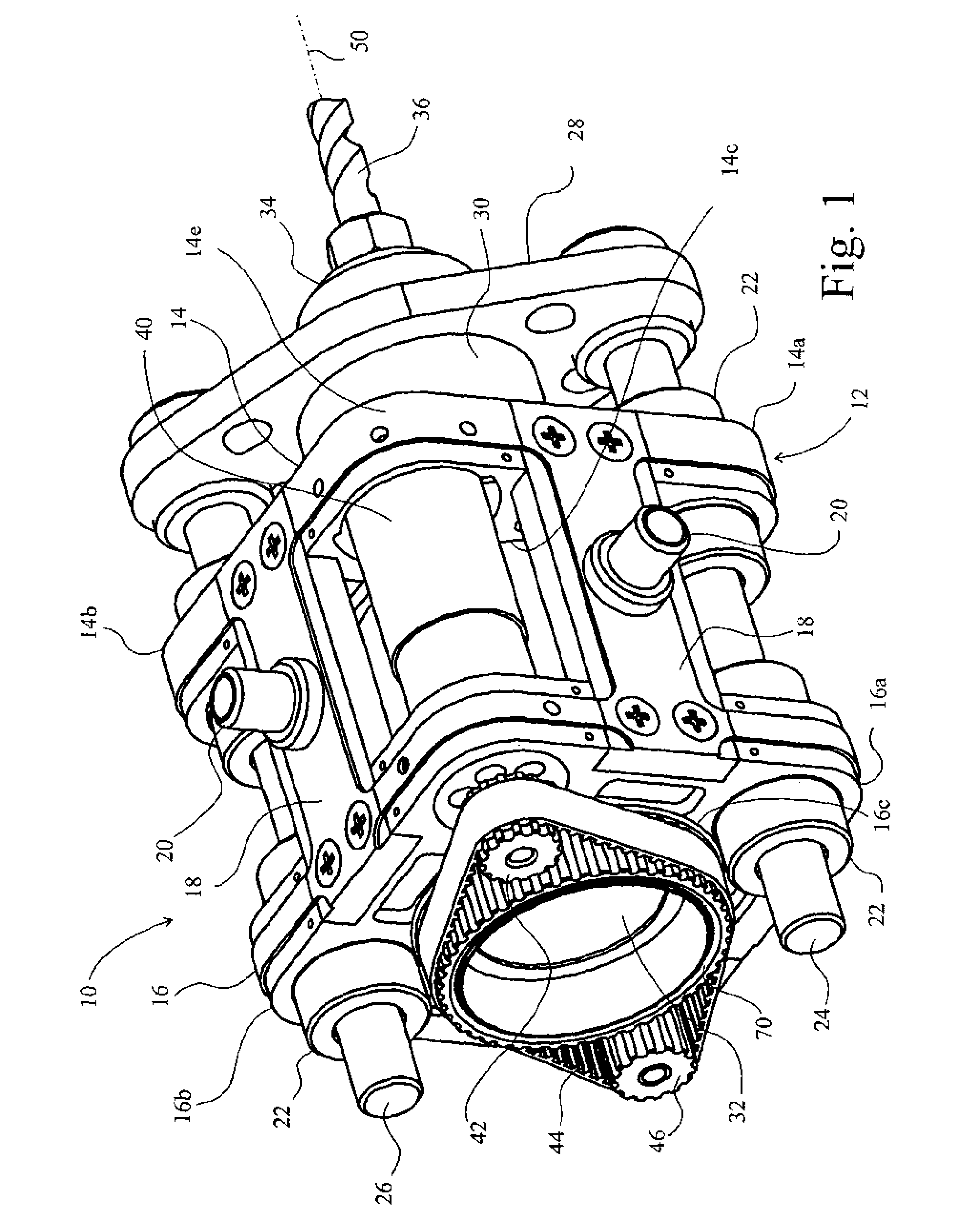

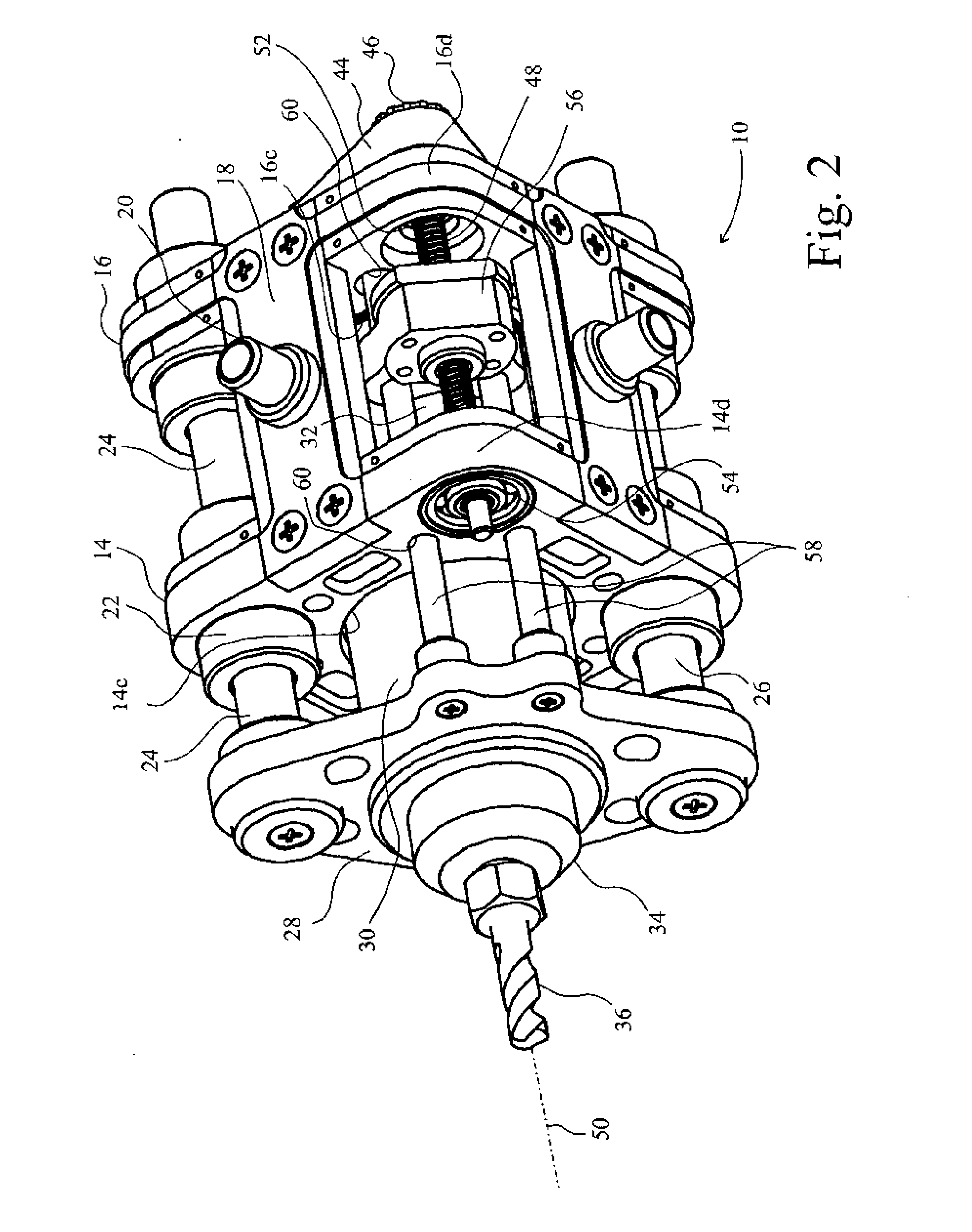

[0088]A drilling tool 10 comprises a frame 12 that has a fore plate 14 and an aft plate 16 connected together by limbs 18. The plates 14, 16 are rounded squares, so that there are four limbs 18. At least one of the limbs incorporates a mounting flange 20 for connection to a robot arm (not shown).

[0089]Opposing corners 14a,b of the fore plate 14 and 16a,b of the aft plate 16 incorporate sleeve bearings 22 through which a pair of pillars 24,26 slide. The pillars 24, 26 are fixed on a yoke 28 on which is also mounted a tool motor 30. The tool motor 30 has a body 32 that is substantially cylindrical and drives an armature (not shown) about a longitudinal axis 50 of the tool 10. A chuck 34 receives a drill bit 36 to be driven by the motor 30 for drilling holes in a workpiece (not shown).

[0090]In drilling holes, it is of course necessary to advance the drill bit 36 in the direction of the hole it is drilling, which is in the direction of axis 50 in FIG. 1. It is of course feasible that a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com