Combustion apparatus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019]Hereinafter, embodiments of the present invention will be described with reference to the drawing figures.

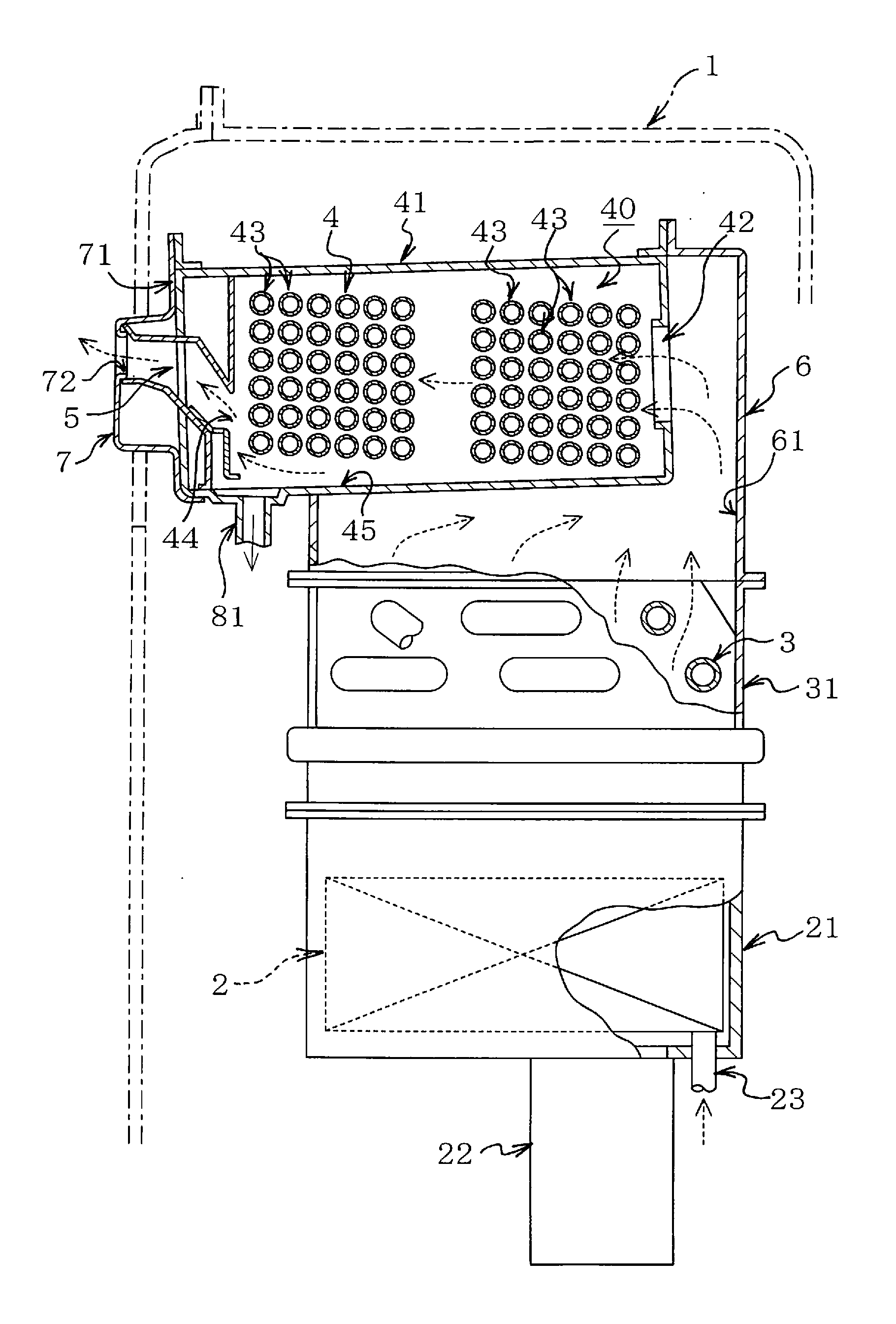

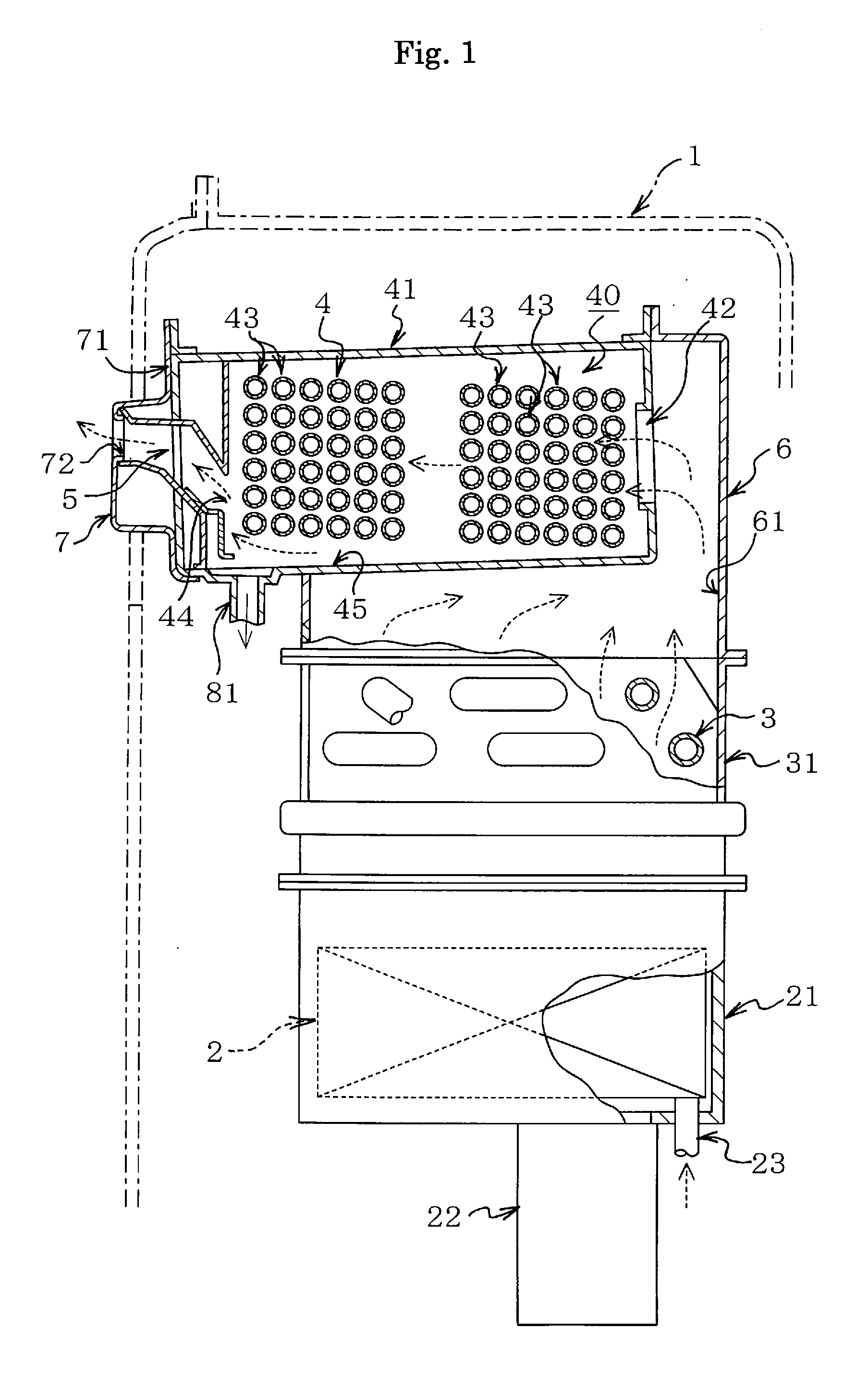

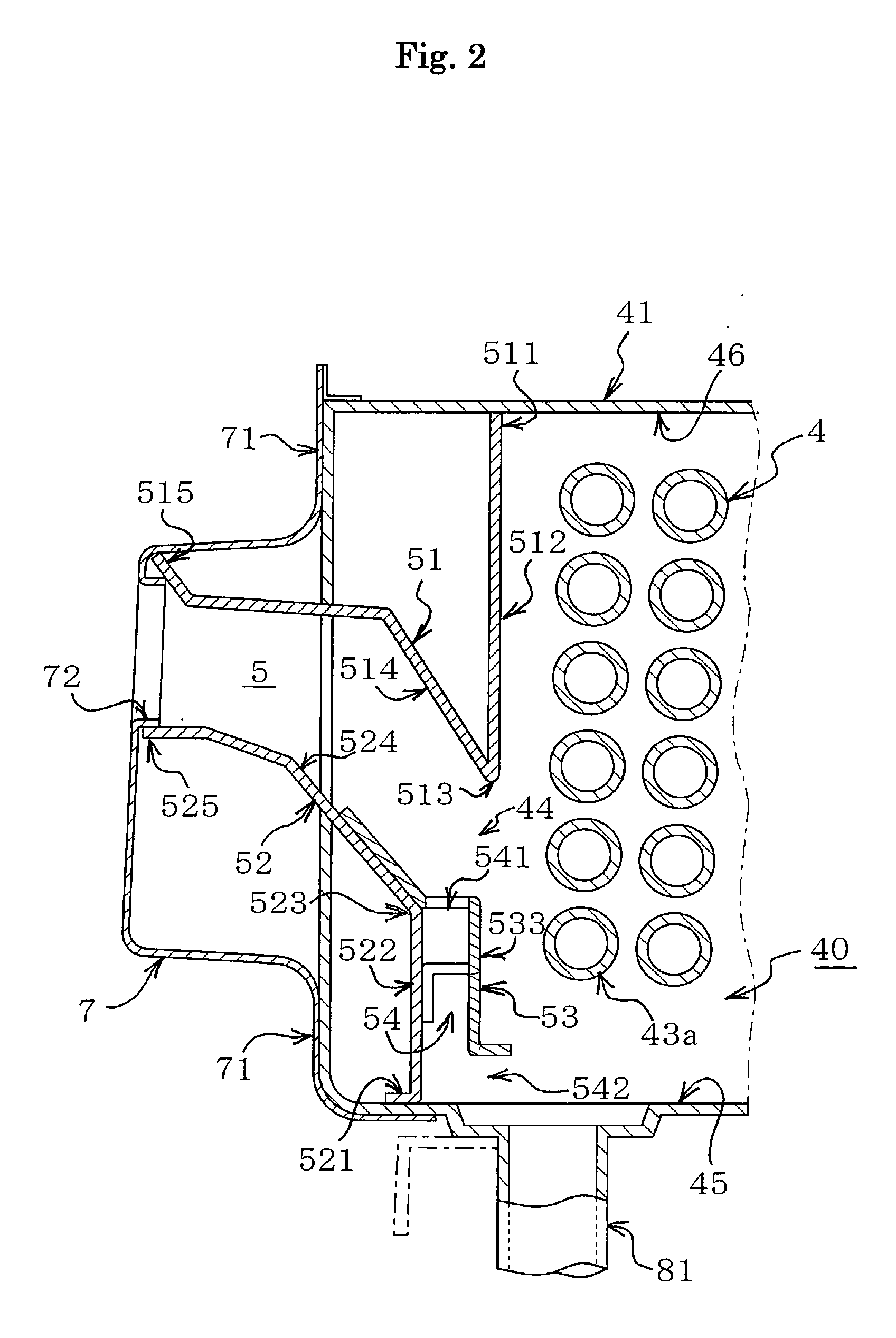

[0020]Referring first to FIG. 1, there is shown a part of a hot water supply heater serving as a combustion apparatus in accordance with an embodiment of the present invention. The hot water supply heater of FIG. 1 is configured as a so-called condensing-type (a latent heat recovery-type) hot water supply heater. More specifically, the combustion apparatus includes, in its housing 1, a combustion burner 2, a primary heat exchanger 3 for effecting heat-exchange heating by the heat of combustion (the sensible heat) of the combustion burner 2, a secondary heat exchanger (a latent heat exchanger) 4 for guiding the combustion exhaust past the primary heat exchanger 3 configured for the recovery of latent heat from the combustion exhaust and an exhaust channel 5 into and from which the combustion exhaust having passed through the secondary heat exchanger 4 is flowed and then dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com