Combustion system

a combustion system and combustion technology, applied in the field of combustion systems, can solve the problems of high carbon content of coal fuel, achieve the effects of reducing the flow rate of exhaust gas, and reducing the capacity of the smoke removal devi

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

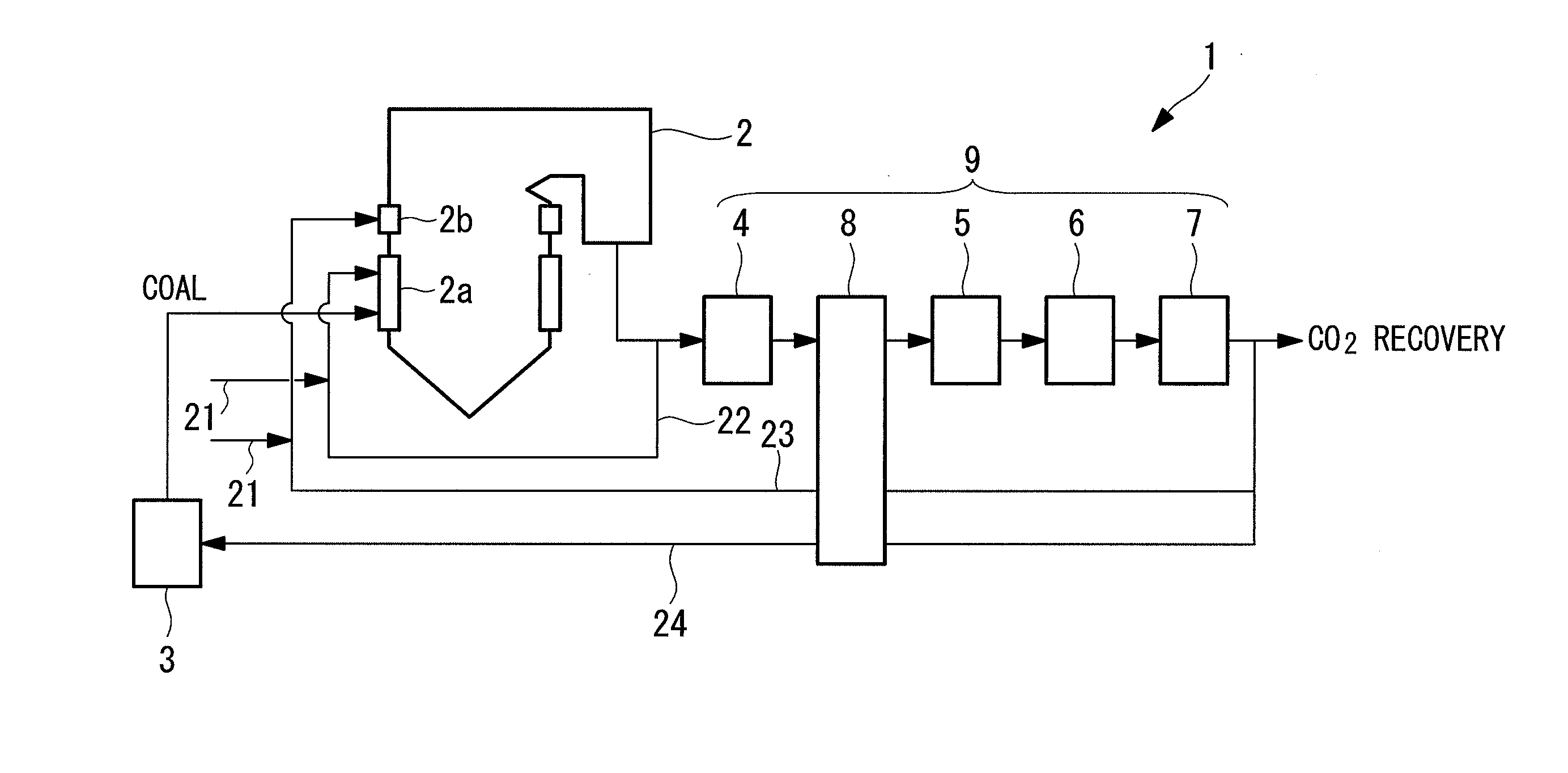

[0035]FIG. 1 is a schematic structure view of a combustion system according to the first embodiment of the present invention.

[0036]The combustion system 1 includes a coal fired boiler (combustion furnace) 2, a coal pulverizer 3 for pulverizing coal supplied to the coal fired boiler 2, and a smoke removal device 9.

[0037]The coal fired boiler 2 is an oxygen combustion boiler which can conduct denitration inside the furnace (not shown) by two-stage combustion. The coal fired boiler 2 includes a furnace inside for combusting fuel, a burner unit 2a, and an additional air port (hereinafter referred to as “AA unit”) 2b. Coal as fuel supplied from the coal pulverizer 3, oxygen (combustion oxygen) introduced from a combustion oxygen supply system 21, and later-described secondary recirculation gas for burner unit 22 are introduced to the burner unit 2a. Remaining part of the oxygen introduced from the combustion oxygen supply system 21 to the burner unit 2a and later-described secondary reci...

second embodiment

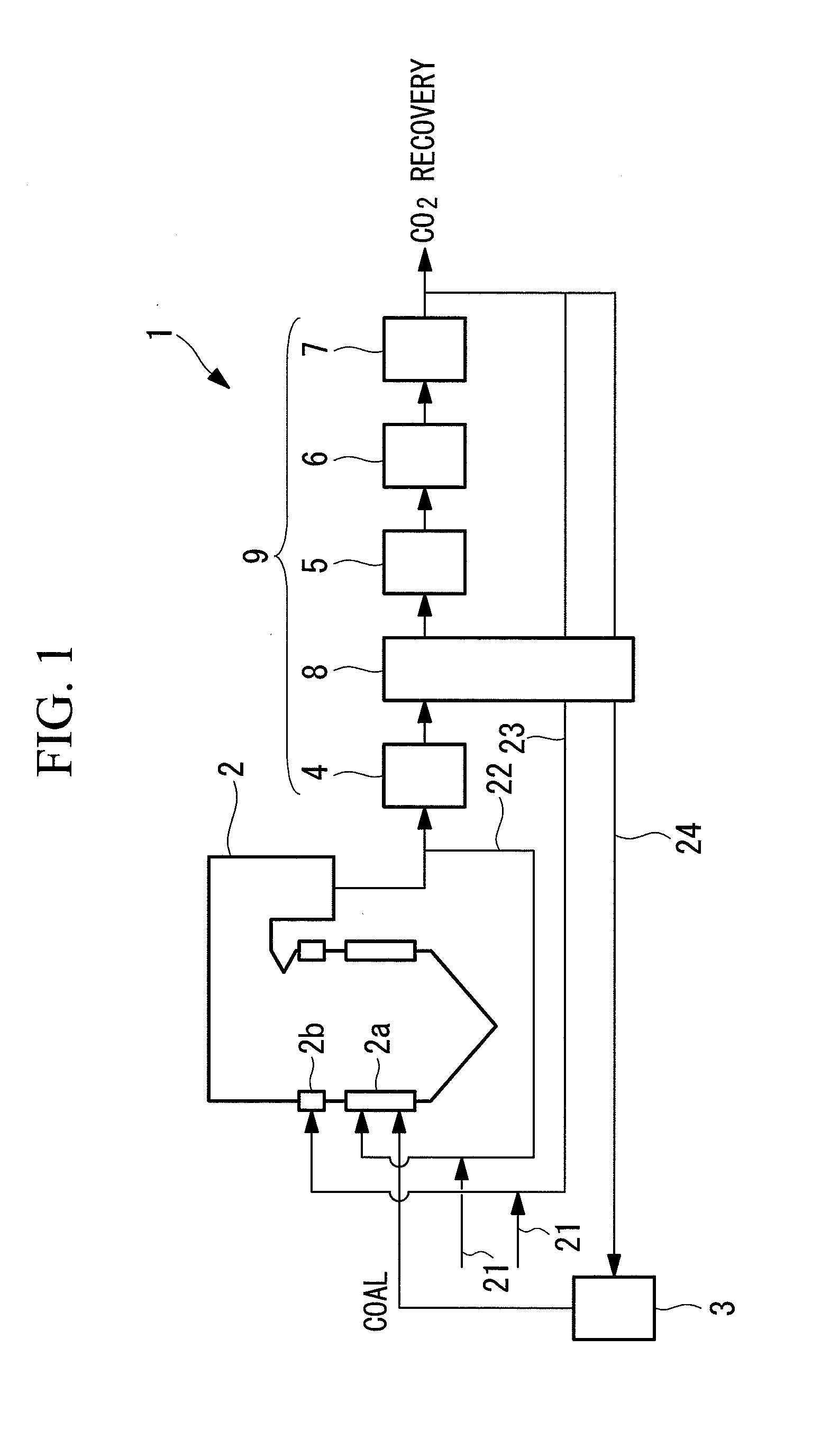

[0061]Hereinafter, the second embodiment of the present invention will be described. A combustion system of the present embodiment is different from the first embodiment in the point that the secondary recirculation gas for AA unit is introduced from between the desulfurization device and the gas cooler. Other structural members are similar to those of the first embodiment. Therefore, like structural members and flows are designated by like reference signs to omit description.

[0062]FIG. 2 is a schematic structure view of a combustion system according to the second embodiment of the present invention.

[0063]Oxygen (combustion oxygen) introduced from a combustion oxygen supply system 21 and part of exhaust gas diverging from between a desulfurization device (desulfurization unit) 6 and a gas cooler (cooling unit) 7 which constitute a smoke removal device 9 are supplied to an AA unit (combustion oxygen supply port) 2b of a coal fired boiler (combustion furnace) 2 as secondary recirculat...

third embodiment

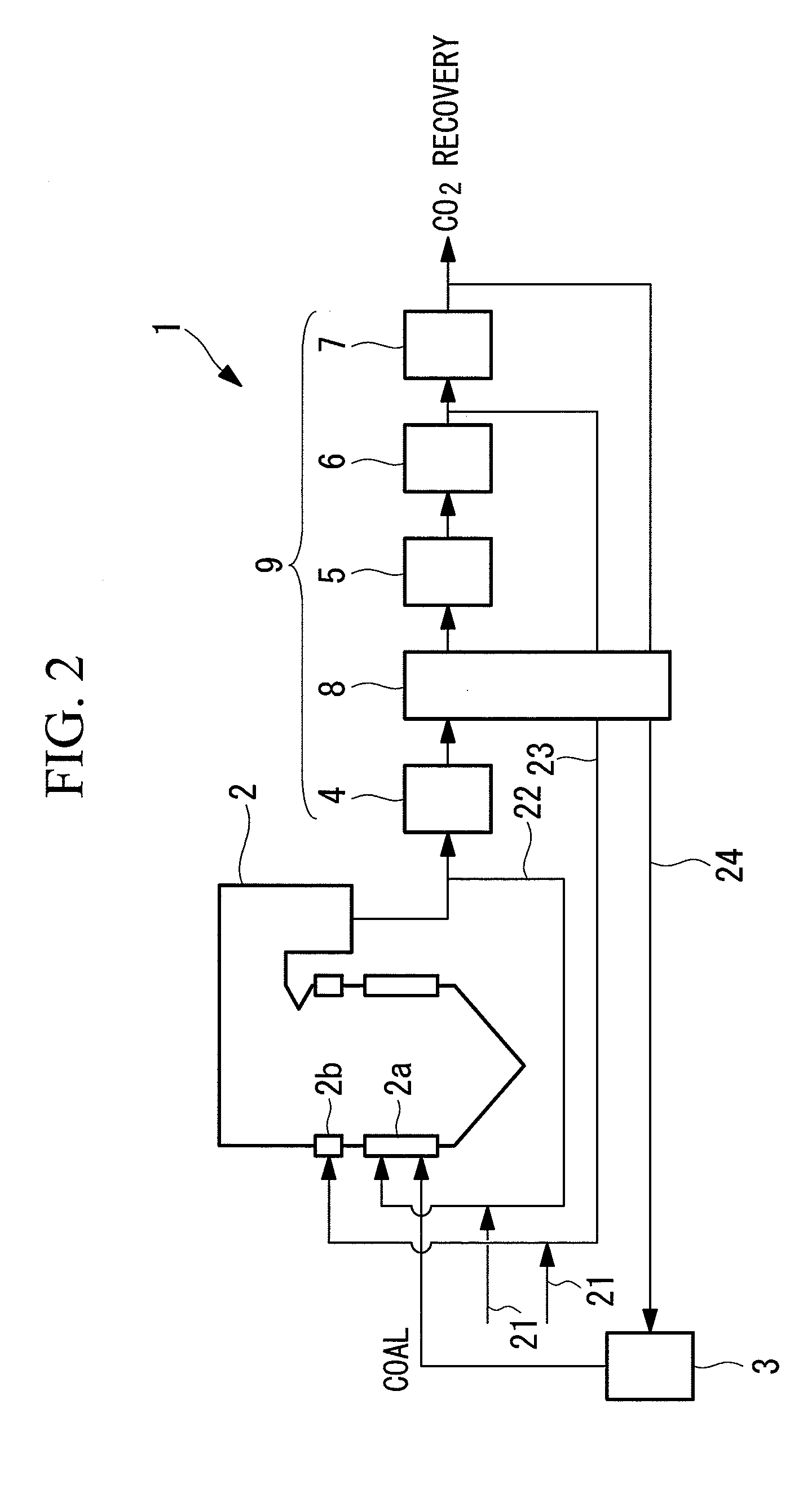

[0066]Hereinafter, the third embodiment of the present invention will be described. A combustion system of the present embodiment is different from the first embodiment in the point that the secondary recirculation gas for AA unit is introduced from between the dust removal device and the desulfurization device. Other structural members are similar to those of the first embodiment. Therefore, like structural members and flows are designated by like reference signs to omit description.

[0067]FIG. 3 is a schematic structure view of a combustion system according to the third embodiment of the present invention.

[0068]Oxygen (combustion oxygen) introduced from a combustion oxygen supply system 21 and part of exhaust gas diverging from between a dust removal device (dust removal unit) 5 and a desulfurization device (desulfurization unit) 6 which constitute a smoke removal device 9 are supplied to an AA unit (combustion oxygen supply port) 2b of a coal fired boiler (combustion furnace) 2 as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com