Liquid-air transpired solar collectors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

LATSC Numerical Model

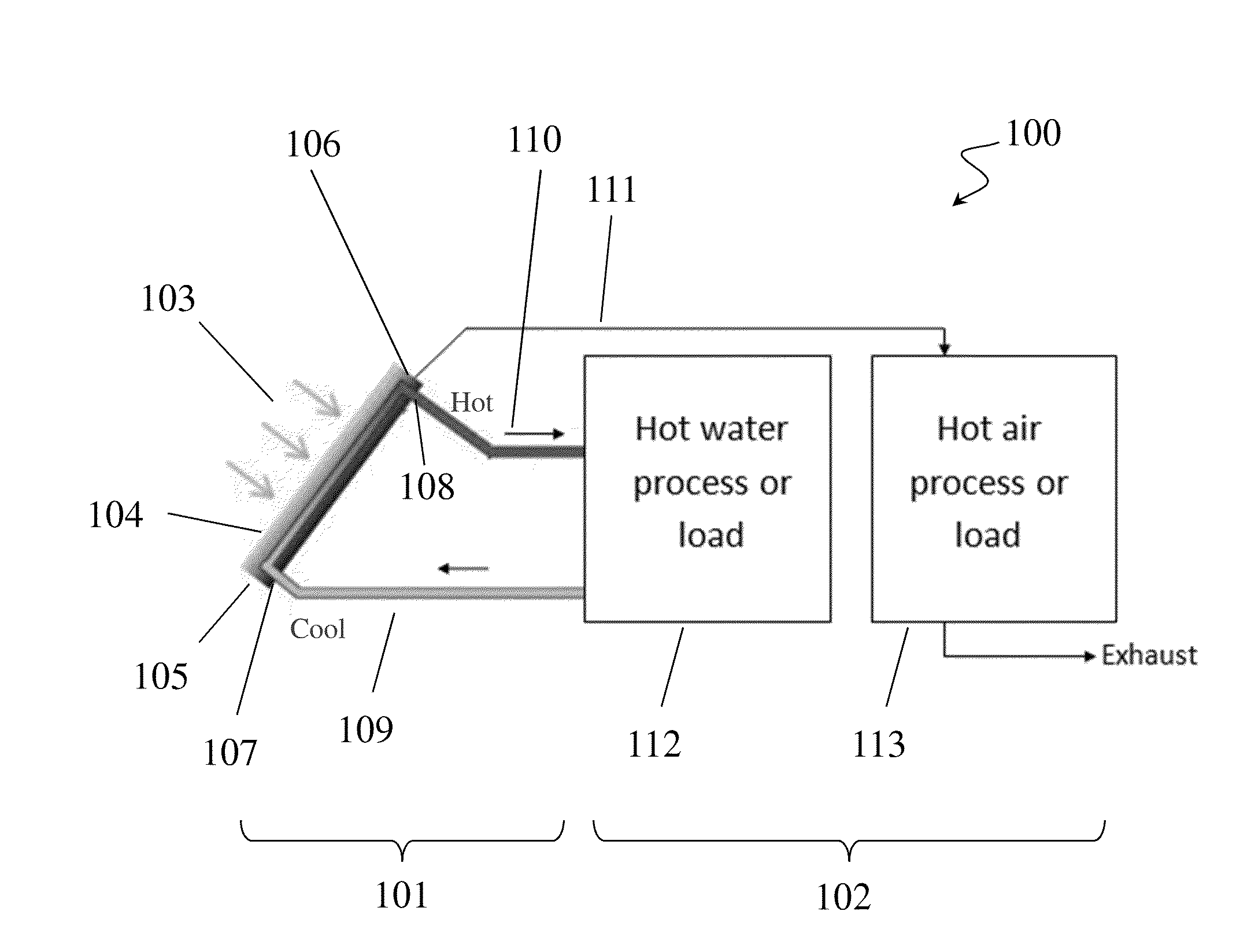

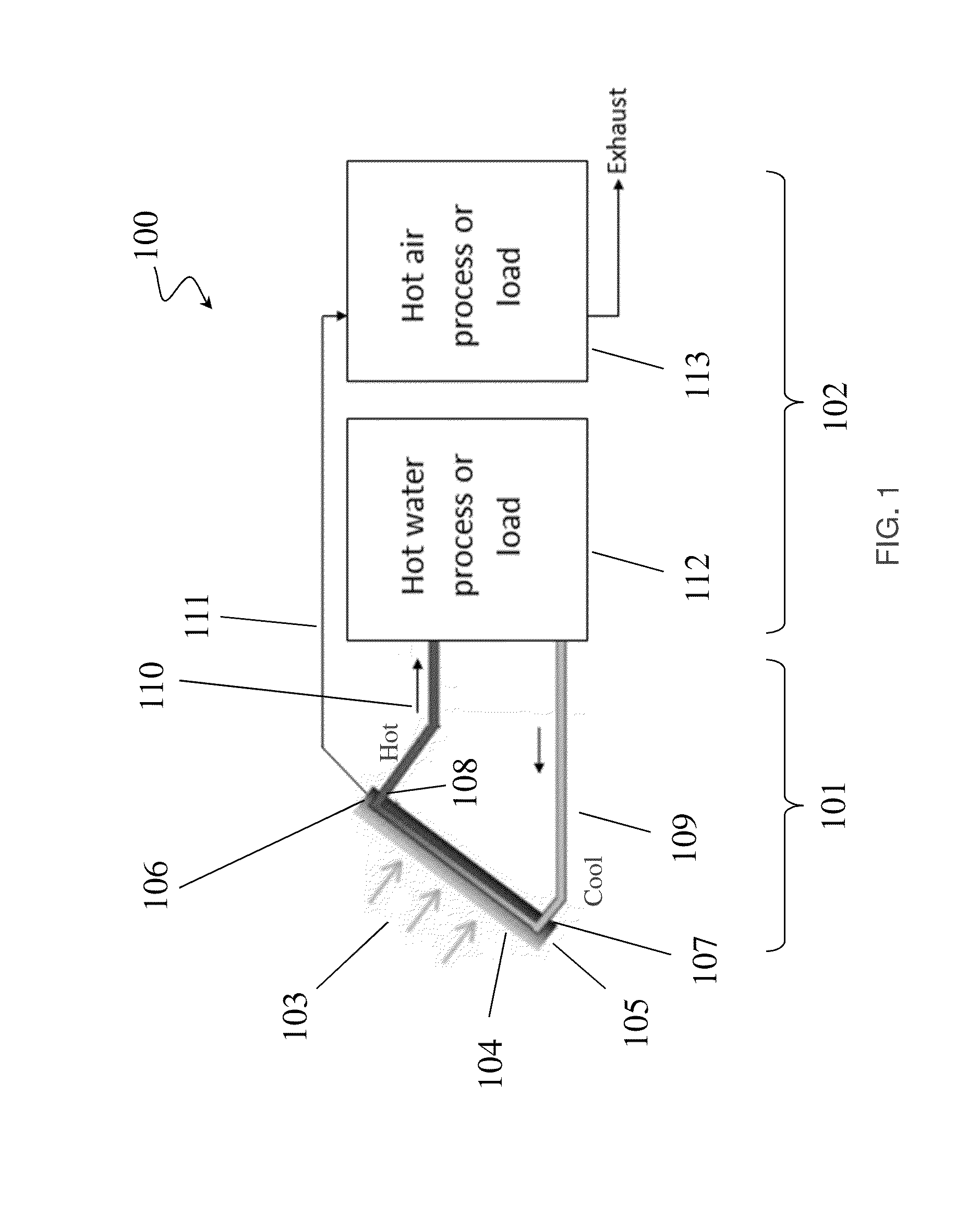

[0090]This example relates to a hybrid solar collector referred to as a Liquid-Air Transpired Solar Collector (LATSC). The LATSC is useful for processes that utilize both hot air and hot water. A schematic of a LATSC supplying heat to two processes is depicted FIG. 1. In developing a numerical model of the LATSC, heat transfer mechanisms from the absorber plate and from the back of the collector were considered.

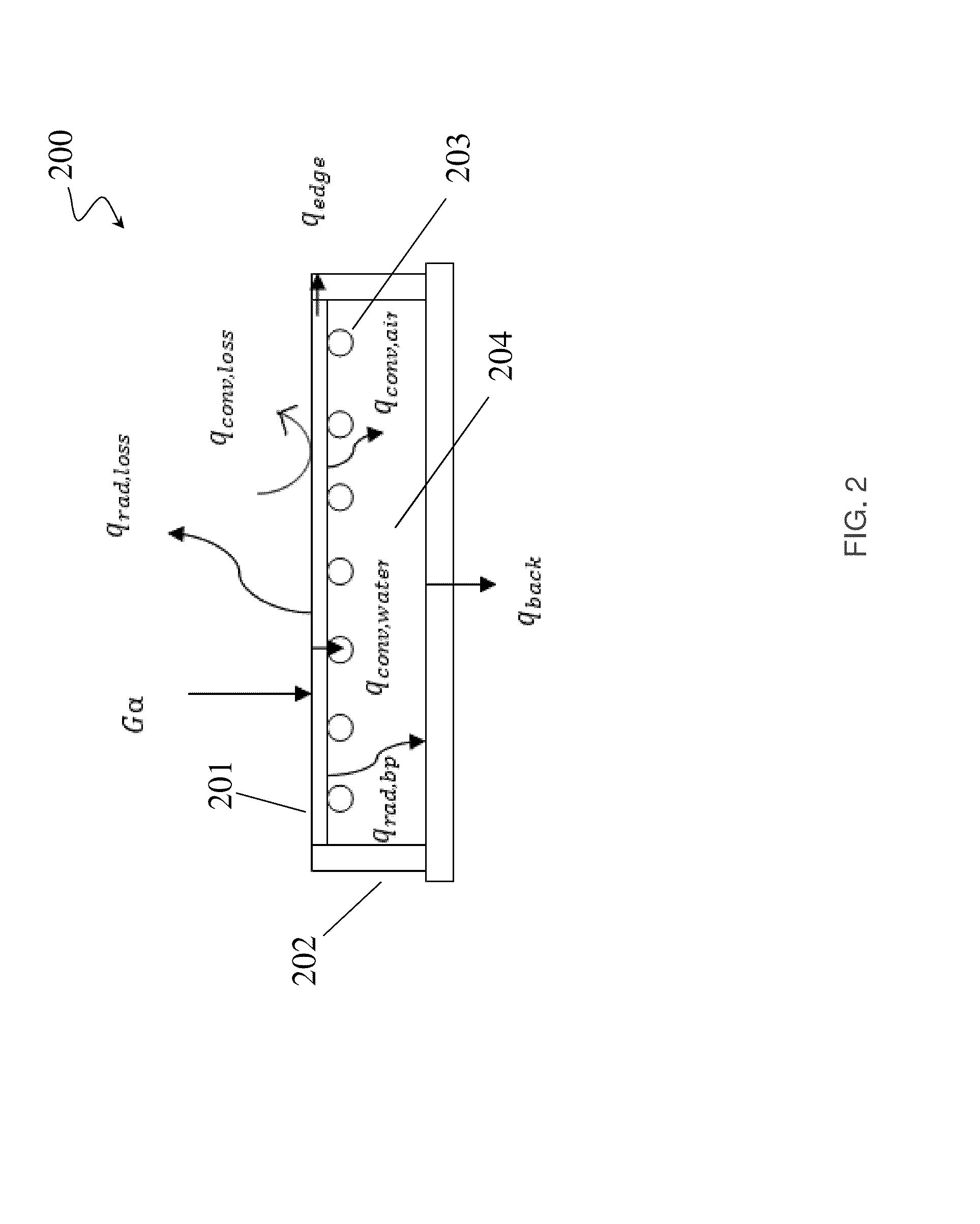

[0091]A schematic diagram in FIG. 2 shows the different modes of heat transfer in a cross-section of a solar energy collector 200. The solar energy collector 200 includes a housing 202 forming a cavity 204 for containing a fluid, and solar absorber 201 connected with the housing 202. The solar energy collector 200 also includes a plurality of conduits 203 in the cavity. Losses were categorized as convective and radiative front of plate losses (qconv,loss, qrad, loss), convective and radiative back of plate losses (qconv,air,qrad,bp) and back of collector ...

example 2

Sensitivity Analysis of the LATSC Model

[0144]With the collector model described in Example 1, the performance sensitivity of the collector to varying the ambient temperature (Tamb), inlet water temperature (Twi), collector emissivity (ε), solar radiation (G), wind speed (Vw) and total thermal capacitance of air and water ({dot over (m)}cp)total was evaluated. Moreover for each analysis, the ratio of thermal capacitance of air to total thermal capacitance (R{dot over (m)}cp) was varied to observe its effect on the efficiency of the collector along with the other varying parameters. The efficiency of the collector was given by:

ηc=m.aCpa(Tao-Tai)+m.wCpw(Two-Twi)G*A(53)

[0145]Two batches of sensitivity analysis were performed. The first batch evaluated the performance of the collector to changes in ({dot over (m)}cp)total and (R{dot over (m)}cp) with other physical and weather parameters held constant while the second batch was aimed at producing performance curves fo...

example 3

Experimental Assessment of LATSC

[0160]To further evaluate the model disclosed in Examples 1 and 2, an experiment was conducted to test a LATSC. A LATSC was constructed which comprises a 2 m2 flat plate, tube-fin type, collector, as depicted in FIG. 32.

[0161]The thermal testing of the collector involved accurate measurement of both the total solar energy incident and the total thermal energy gain of the collector. The solar energy incident was measured by the use of pyranometers and accurate measurement of the collector absorber area. Assessment of the thermal energy gain involved the measurement of the inlet and outlet temperatures of air and water as well as their respective flow rates. The total thermal energy gain of the collector was given by:

Qu,tot=[{dot over (m)}Cp(Tout−Tin)]a+[{dot over (m)}Cp(Tout−Tin)]w (55)

[0162]The specific heat capacity of water and air were calculated in EES using established property data as a function of temperature and pressure.

[0163]The efficiency ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com