Lithium-ion battery electrodes with shape-memory-alloy current collecting substrates

a technology of shape memory and current collector, which is applied in the direction of cell components, electrochemical generators, transportation and packaging, etc., can solve the problems of rapid capacity degradation, low capacity for such lithium insertion, and fracture of active silicon material, so as to reduce the energy capacity of the cell and reduce the stress on the cell

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

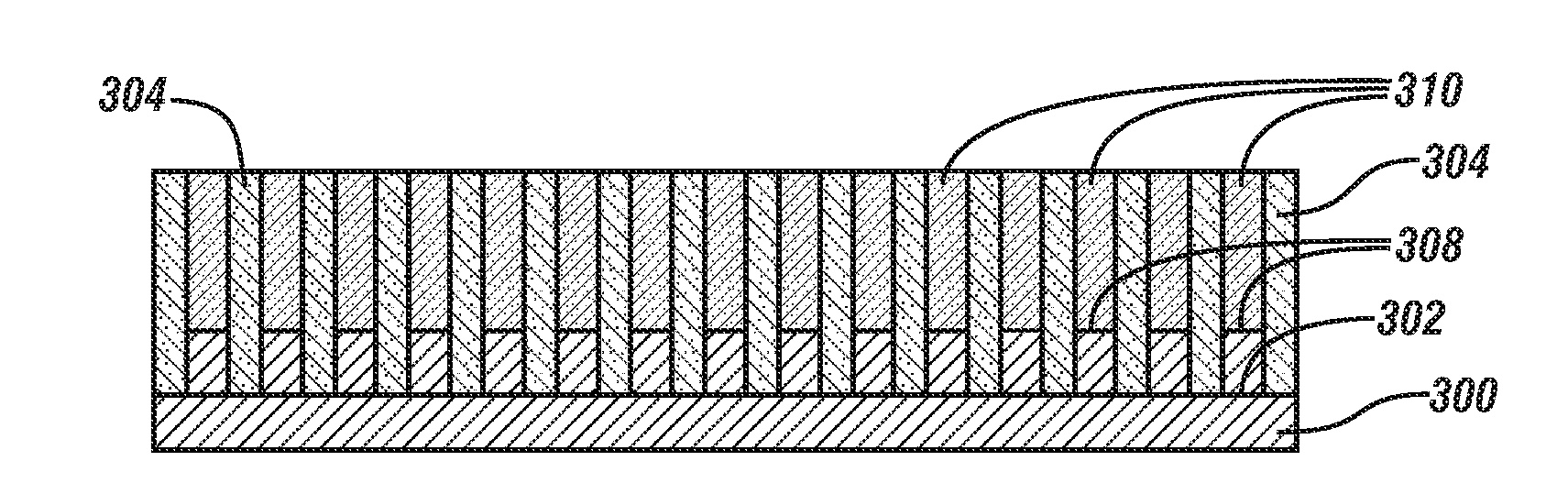

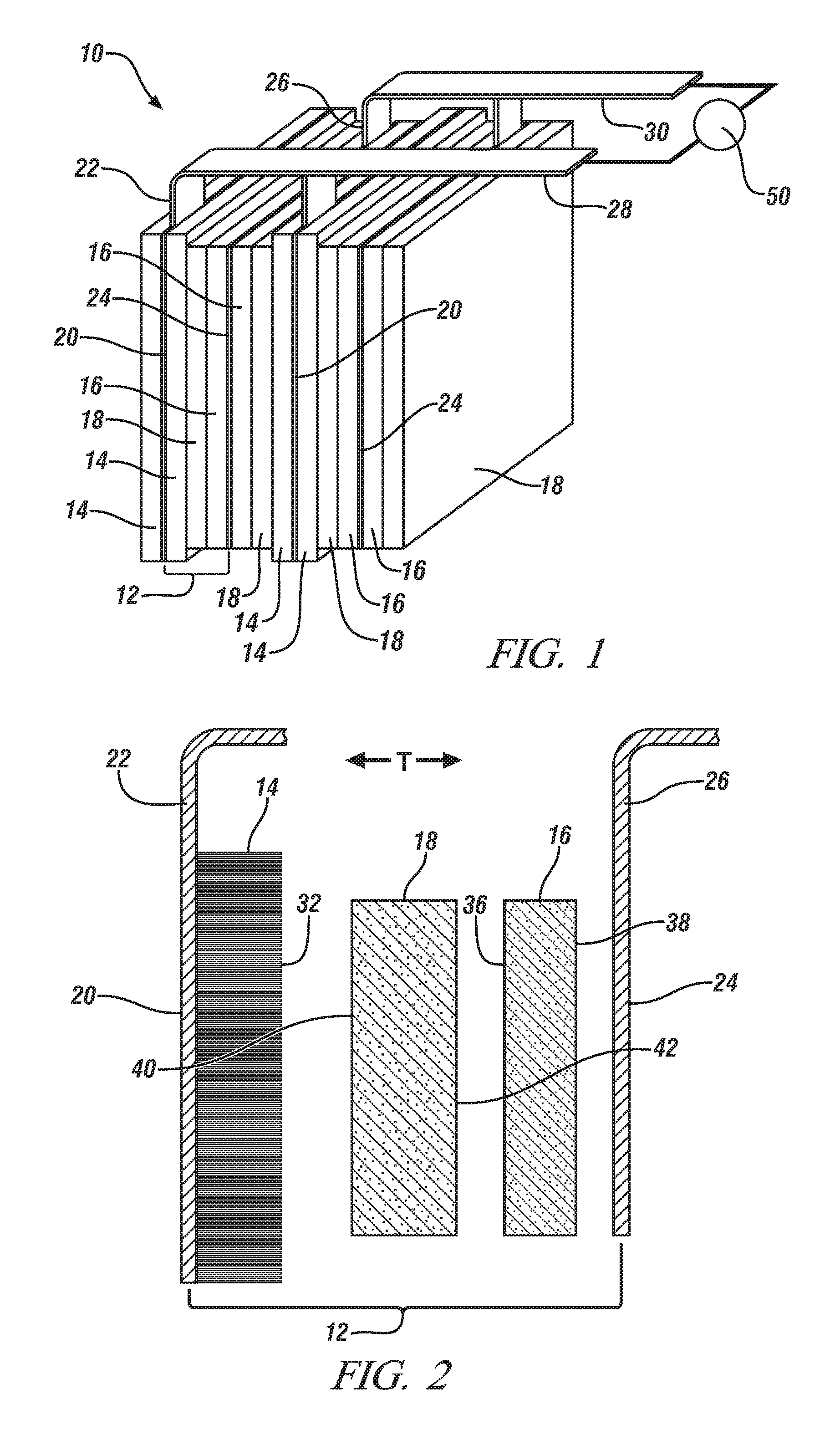

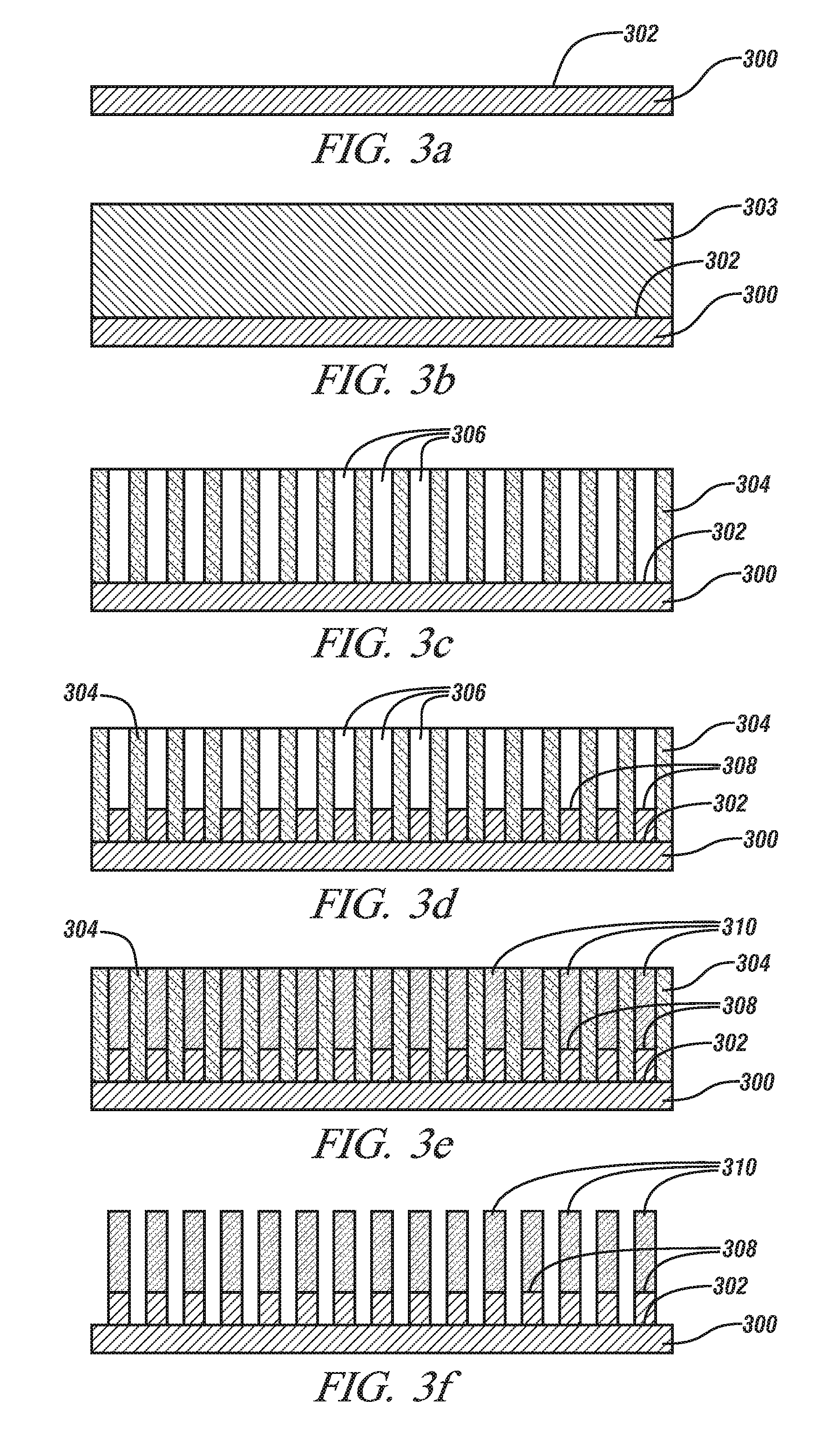

[0021]An exemplary and generalized illustration of a lithium-ion battery 10 is depicted in FIG. 1. The lithium-ion battery 10 shown here includes several thin rectangular-shaped electrochemical battery cells 12 that are each bracketed by metallic current collectors. The electrochemical battery cells 12 are stacked side-by-side in a modular configuration and, in this example, connected in parallel. A lithium-ion battery 10 may be formed of many like electrochemical cells in electrical series or in parallel connection to form a lithium ion battery that exhibits the voltage and current capacity demanded for a particular application. It should be understood the lithium ion battery 10 shown here is only a schematic illustration. FIG. 1 is presented to show the relative position and physical interactions of the various components that constitute the electrochemical battery cells 12 (i.e., the electrodes and the separator); it is not intended to inform the relative sizes of the electrochem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thicknesses | aaaaa | aaaaa |

| thicknesses | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com