Catalysts Having Mixed Metal Oxides

a technology of mixed metal oxides and catalysts, applied in the field of electrocatalysts, can solve the problems of mixing metal oxide catalysts, difficulty in search for further improved mixed metal oxide anodes for oxygen formation or consumption reactions, and one or more deficiencies, etc., to achieve the effect of high quantity, low cost and more commercially practicabl

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

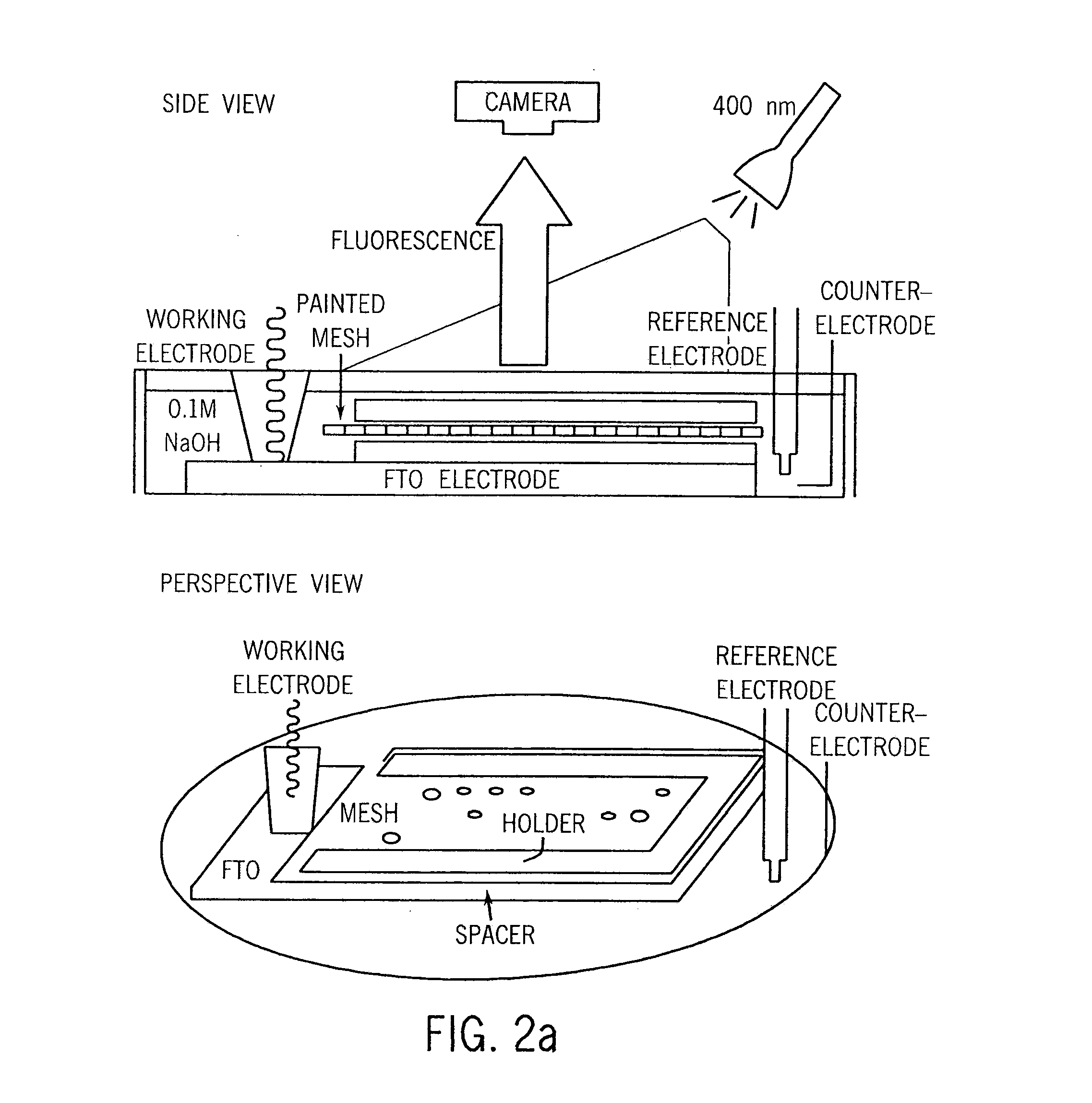

[0038]We developed the FIG. 2 apparatus having an anode with an array of varied mixes of metal oxide compositions, an electrolyte bath, and an optical system for detecting oxygen evolution. As the anode was brought to overpotential, different points in the array had varied oxygen production rates.

[0039]To measure which oxide mixtures had which oxygen production, we use a mesh coated with an oxygen-sensitive paint (Binary Unicoat Pressure Sensitive Paint available from Innovative Science Solution), held parallel to the anode at a small distance from it. The mesh fluoresced green in the presence of, or both red and green in the absence of, oxygen. The emitted light was detected by a camera. Sequential images of the mesh were processed to determine the magnitude of the shift in fluorescence over a given spot in the array. These images were calibrated by co-observation of reference regions of known electrocatalytic activity in the array.

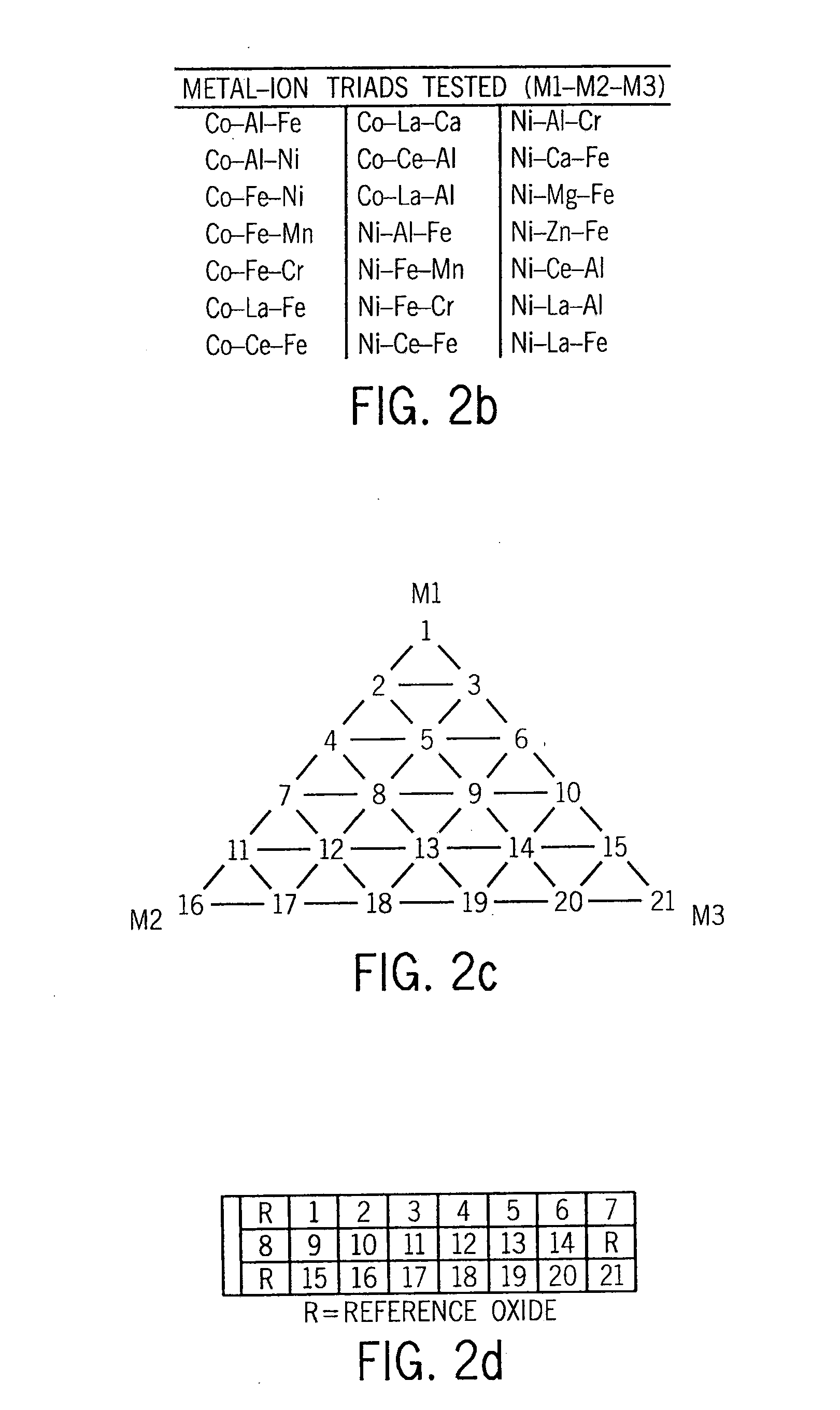

[0040]As represented by the depictions in FIGS. 2b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pH | aaaaa | aaaaa |

| pH | aaaaa | aaaaa |

| weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com