Liquid Fuel Combustion System

a combustion system and liquid fuel technology, applied in the direction of combustion types, domestic stoves or ranges, lighting and heating apparatus, etc., can solve the problems of high cost of lpg, and potential explosion hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

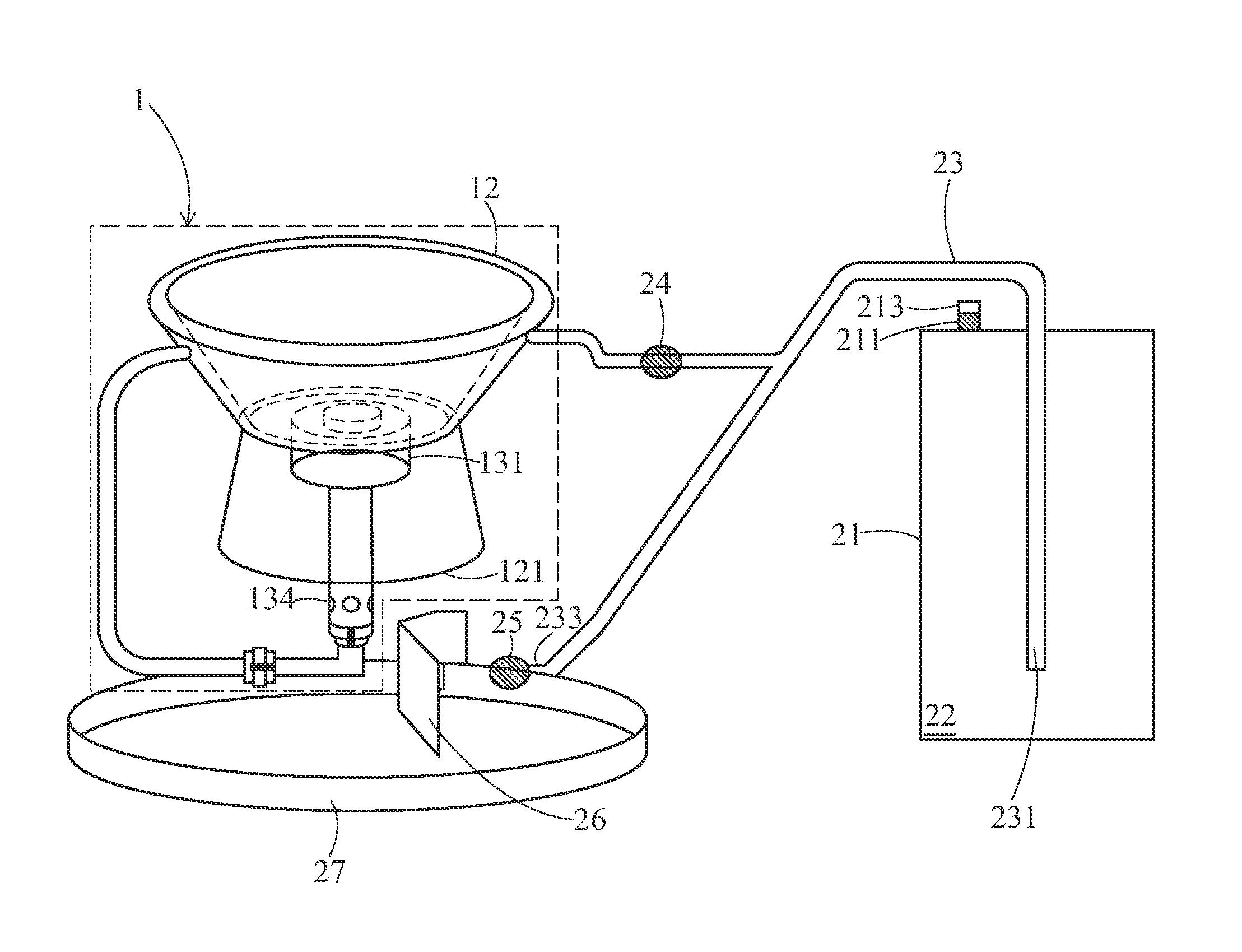

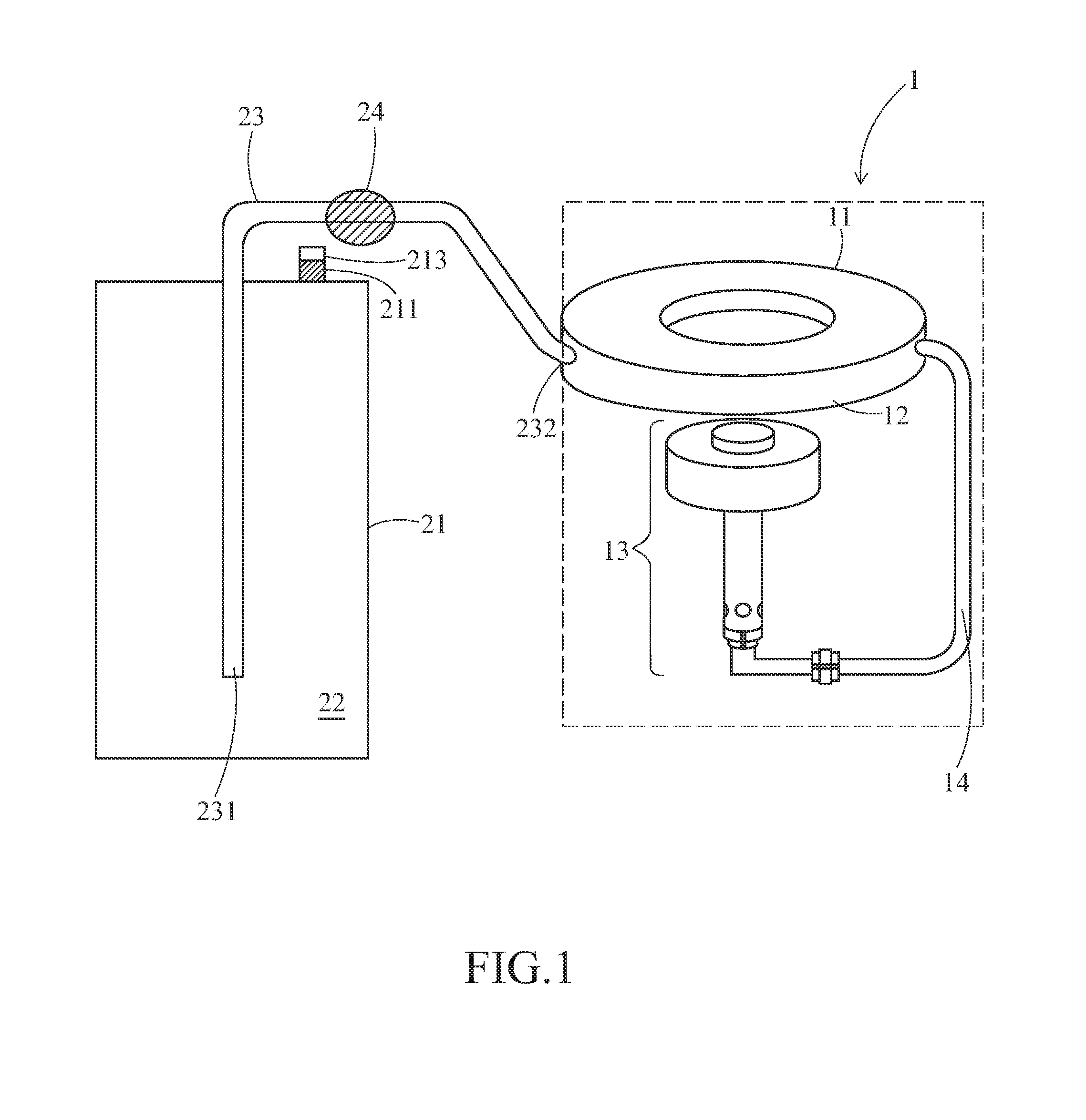

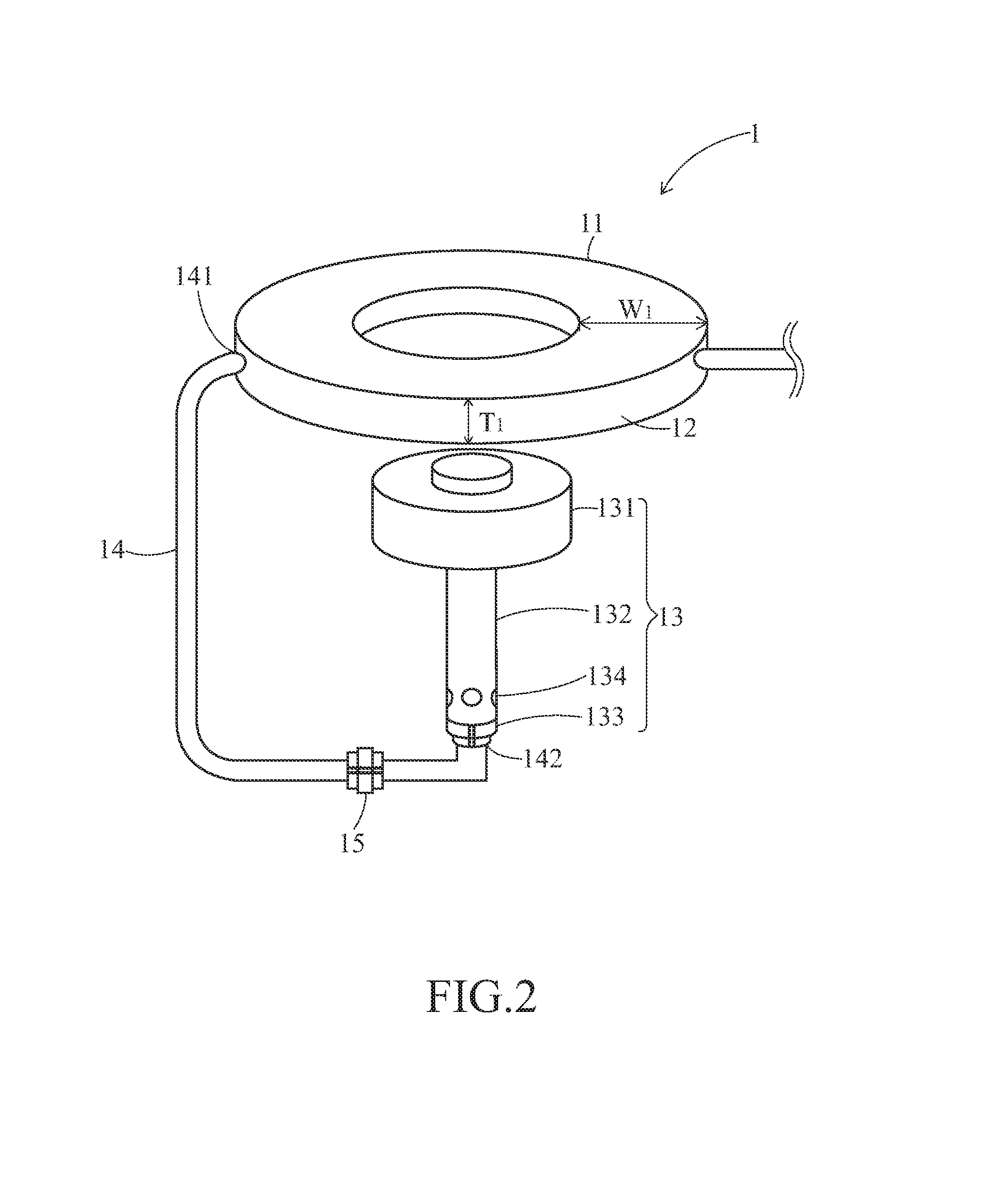

Image

Examples

examples

[0062]According to the ratio indicated in Tables 1 to 6, the liquid fuel (methanol or cleaning naphtha) or the mixture of the liquid fuel and stabilizer and / or heat transfer promoter were loaded into the storage space of liquid fuel storage tank to provide liquid fuel compositions, and a predetermined amount of ignition promoter was then added into the storage space. The liquid fuel storage tank was then shaken to uniformly mix the components of liquid fuel composition. The pressure of the liquid fuel storage tank was measured and recorded in the tables.

[0063]Thereafter, the flow rate of liquid fluid composition was controlled in the range of about 10 g / min to about 20 g / min. An electric igniter was disposed adjacent to the burning head to provide an arc to ignite the liquid fuel composition. The required time period to ignite the liquid fuel composition while obtain a steady flame strength (ignition time θ) was measured and recorded in the tables respectively. After obtaining the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com