Conductive pastes for forming solar cell electrodes

a solar cell and electrode technology, applied in the direction of electrically-conductive paints, conductors, final product manufacturing, etc., can solve the problems of increasing development costs, not having sufficient guidelines in the art, and many trial and error, and achieve good solar cell characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

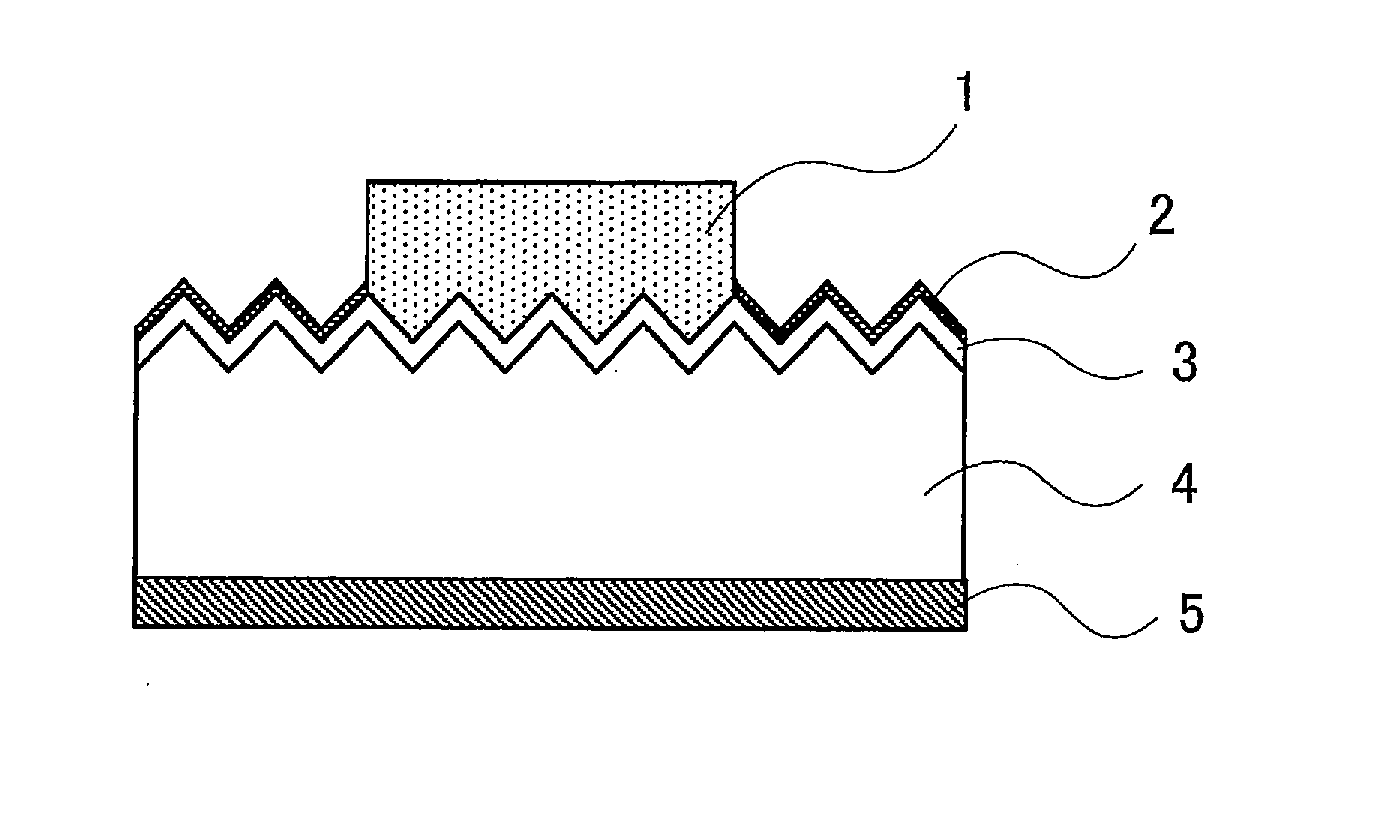

Image

Examples

examples

[0101]Hereinbelow, the present invention will be described in detail by presenting examples without limiting the scope of the invention to such examples.

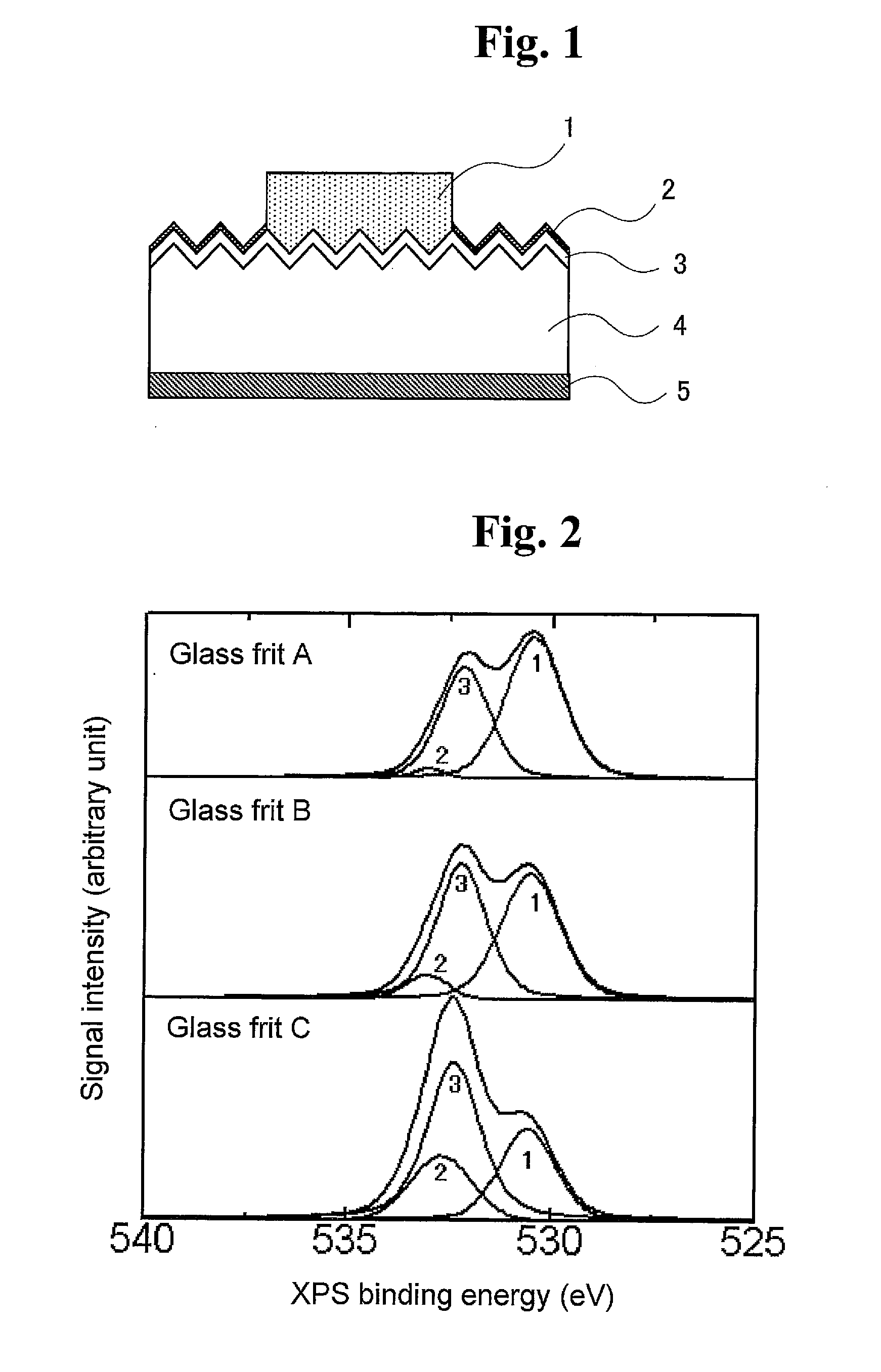

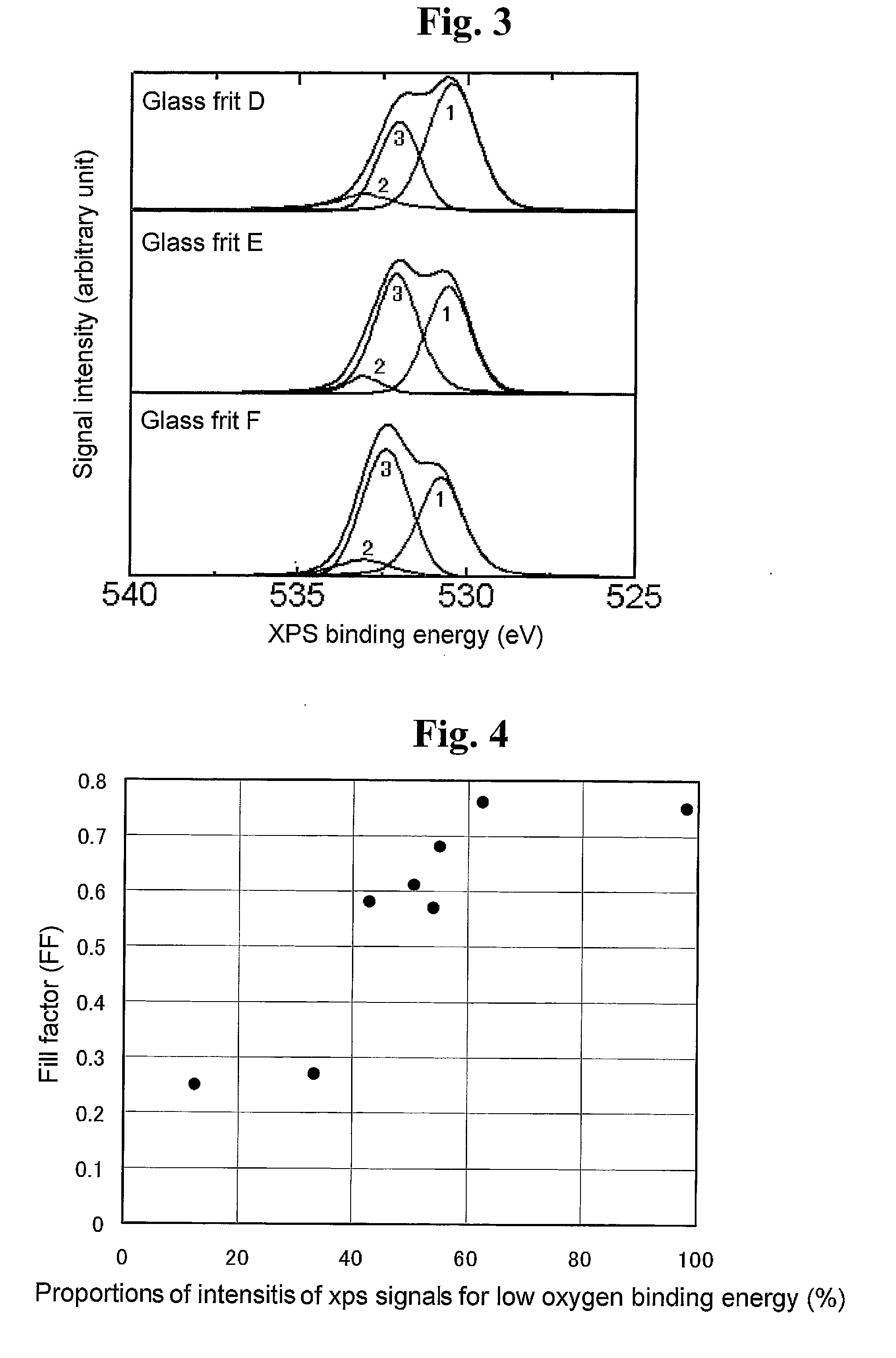

[0102]Compositions of conductive pastes used for the production of solar cells in examples and comparative examples are as follows.[0103]Conductive powder: Spherical Ag particles (100 parts by weight) were used which had a BET value of 0.6 m2 / g and a median particle diameter D50 of 1.4 μm.[0104]Glass fits: Glass frits A to H with the compositions shown in Table 1 were used. Table 2 shows the amounts of the glass fits added to 100 parts by weight of the conductive powder in the conductive pastes of examples and comparative examples. The median particle diameter D50 of the glass frits was 2 μm.[0105]Organic binder: Ethylcellulose (1 part by weight) containing 48 to 49.5 wt % of ethoxy was used.[0106]Solvent: Butylcarbitol (11 parts by weight) was used.

[0107]The above materials were mixed together at the specified proportions using a p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| binding energies | aaaaa | aaaaa |

| binding energies | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com