Dissymmetric particles (janus particles), and method for synthesizing same by means of bipolar electrochemistry

a technology of dissymmetric particles and bipolar electrochemistry, which is applied in the field of dissymmetric particles, can solve the problems of not being compatible with a conventional industrial environment, unable to finely adjust the drive force of the modification, and difficult to prepare large quantities of particles, etc., and achieves the effect of high flexibility of us

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

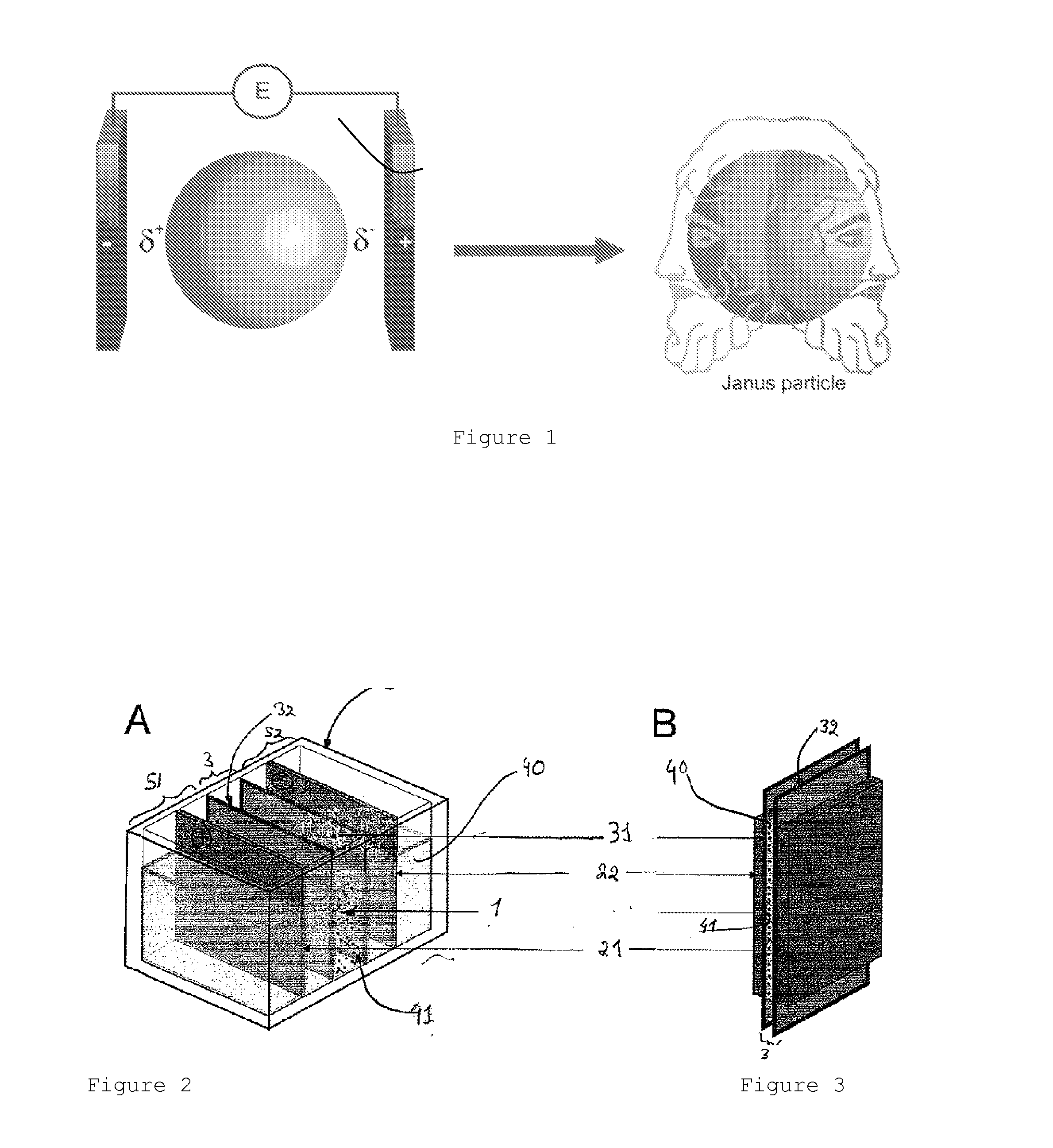

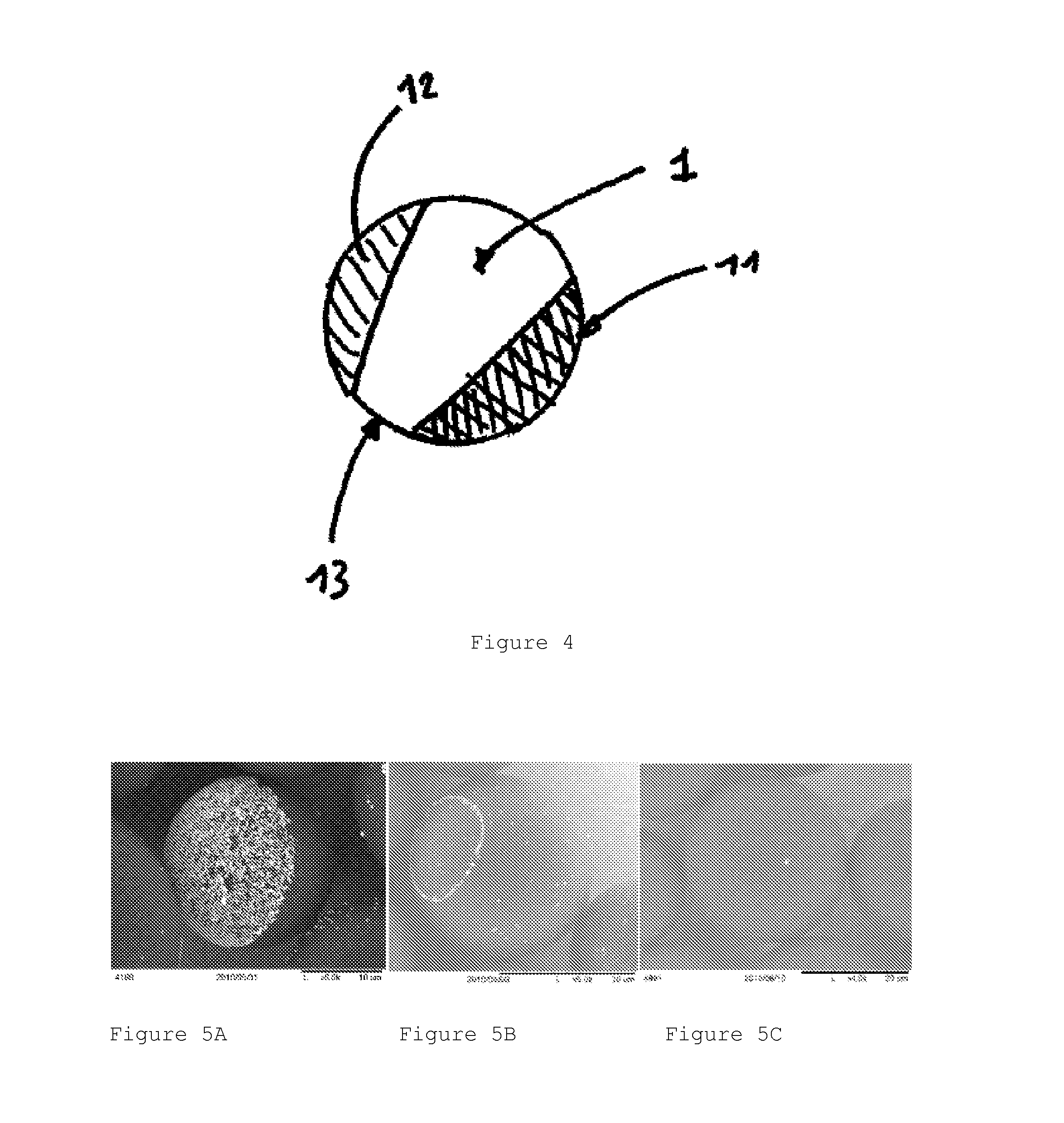

[0086]Synthesis of micron Janus particles according to an embodiment of the invention, monofunctionnalized using the device represented in FIG. 2

[0087]Monofunctionnalized Janus particles were synthesized in accordance with the method according to an embodiment of the invention by using the electrodeposition device represented on FIG. 2 wherein:[0088]a potential difference E of the order of 2 kV is imposed between the electrodes, resulting in an electric field E of 100 kVm−1 in the electrodeposition cell,[0089]the separators are proton exchange membranes or sintered glass plates, and[0090]the electrodes 21, 22 are immersed in ethanol at −100° C. (to compensate for the effects of ohmic heating in the reactor) and at a distance of the order of 2 cm from each other.

[0091]The substrates 1 used are either carbon tubes (images 6A1, 6A2 and 6A3) or vitreous carbon beads (images 6B1, 6B2 and 6B3), the electrolytic solutions 40 are aqueous solutions which, as a source of electrodepositable ma...

example 2

[0094]Synthesis of micron Janus particles according to an embodiment of the invention, monofunctionnalized using the device represented on FIG. 3

[0095]Monofunctionnalized Janus particles were synthesized in accordance with the method according to an embodiment of the invention by using the electrodeposition device represented on FIG. 3 wherein:[0096]a potential difference E of the order of 6 kV is imposed between the electrodes, resulting in an electric field E of 20 MV m−1 in the electrodeposition cell,[0097]the separators are thin glass walls of 100 m and separated from each other also by 100 m;[0098]the substrates 1 used are either 1 carbon tubes (images 6A1 and 6A4) or vitreous carbon beads (images 6B1 and 6B4),[0099]the electrolytic solution 40 is a hydrogel of agar, which contains, as a source of electrodepositable material, the gold chloride AuCl4− at 10 mM (image 6A4) and gold chloride AuCl4− at 1 mM (image 6B4).

[0100]It was observed by scanning electron microscopy (SEM) the...

example 3

Synthesis of submicron Janus particles according to embodiments of the invention, monofunctionnalized by using the device represented on FIG. 2:

[0101]Monofunctionnalized Janus particles were synthesized in accordance with the method according to an embodiment of the invention by using the electrodeposition device represented on FIG. 2 wherein:[0102]a potential difference E of the order of 2 kV is imposed between the electrodes, resulting in an electric field of 100 kV m−1 in the electrodeposition cell;[0103]the separators are proton exchange membranes or sintered glass plates;[0104]the electrodes 21, 22 are immersed in ethanol at −100° C. (to compensate for the effects of ohmic heating in the reactor) and at a distance of the order of 2 cm from each other;[0105]the substrates 1 used are vitreous carbon beads; and[0106]the electrolytic solution 40 is a hydrogel of agar, which contains, as a source of electrodepositable material, gold chloride AuCl4− at 10 mM.

[0107]It was observed by ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| electrically conductive | aaaaa | aaaaa |

| insulating | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com