Method and Apparatus for Reducing Organic Waste by Rotary Desiccation

a technology of organic waste and desiccation chamber, which is applied in the direction of drying machines, light and heating equipment, grain treatment, etc., can solve the problems of increasing the difficulty of finding acceptable locations for new ones, environmental damage, and inconvenience and noise of continuous large-scale truck traffic, so as to reduce the weight and volume of organic waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031]The Invention uses a combination of mechanical disruption and thermal desiccation to remove water and break down the material. No chemical or biological agents are used in the process.

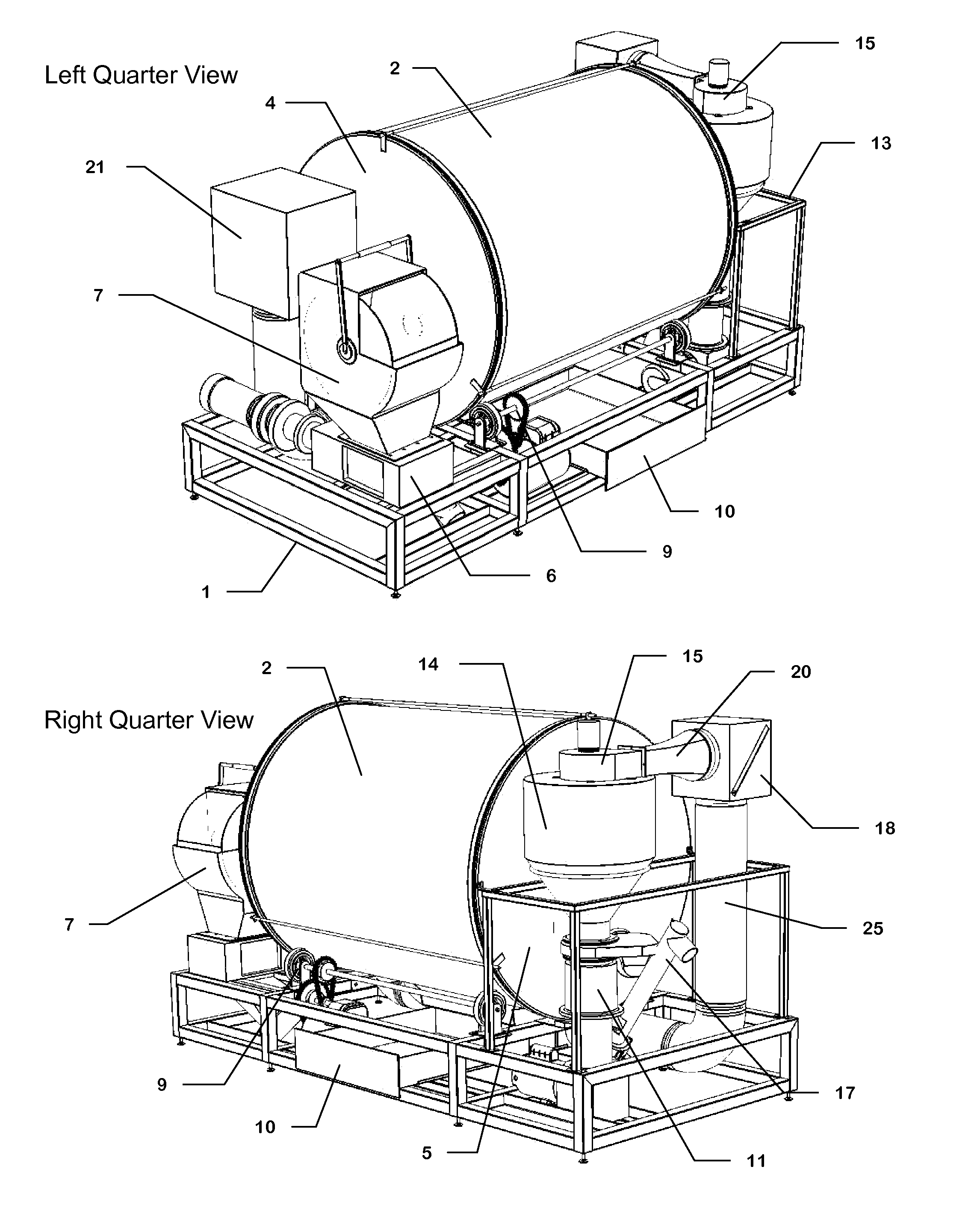

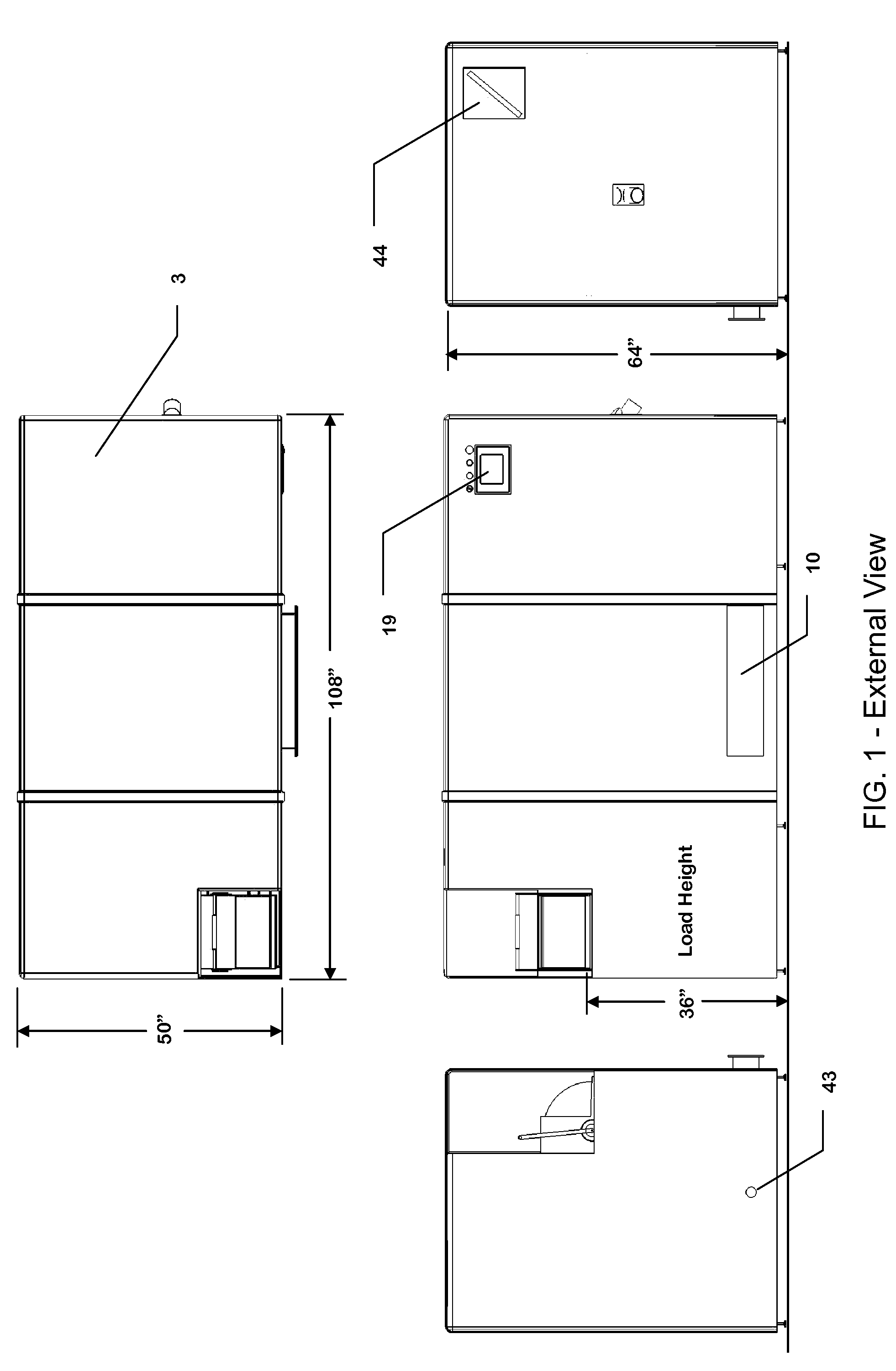

[0032]FIG. 1—External Shape and Size of the Invention.

[0033]The Invention is designed to occupy the same footprint as a standard green-waste dumpster such as used in a commercial kitchen and operate in the same manner, i.e. open it up and dump in the waste. The feed hopper is placed at an ergonomic 36″ from the floor to eliminate the need for lifting heavy waste containers above shoulder height.

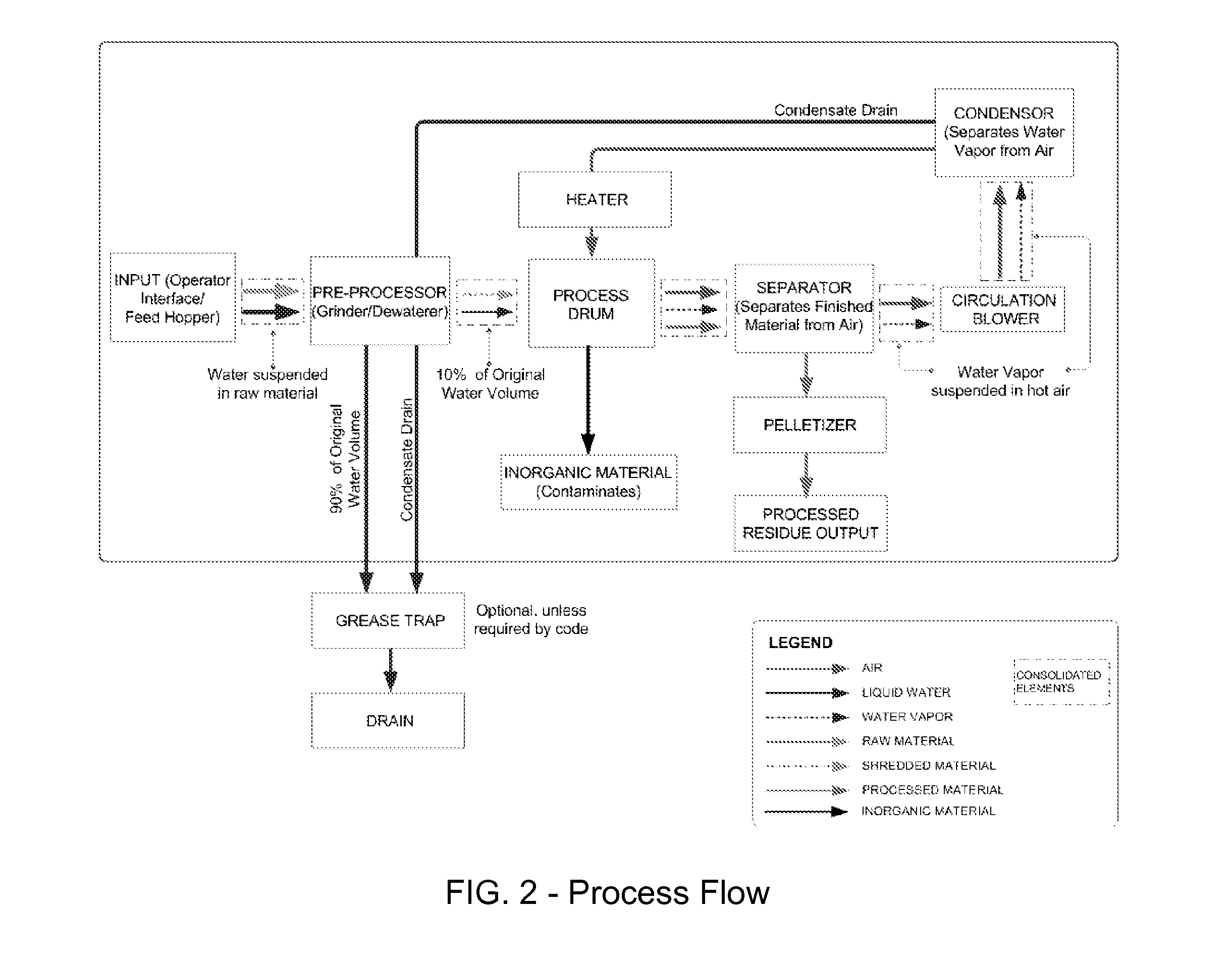

[0034]FIG. 2—Process and Material Flow

[0035]The organic waste is placed into the isolating feed hopper (left side of diagram) that gravity feeds into the pre-processor. The pre-processor shreds the material using an industrial-grade grinder then removes ˜90% of the existing water with an auger press. The de-watered material is fed into the process drum to continue processing.

[0036]The process drum tumbles ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com