Rollback protection system and method

a technology of protection system and rollback protection, which is applied in the direction of vehicle position/course/altitude control, process and machine control, instruments, etc., can solve the problems of introducing lag time and error, inability to see movement, and tendency to roll back, so as to prevent the effect of rolling back

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

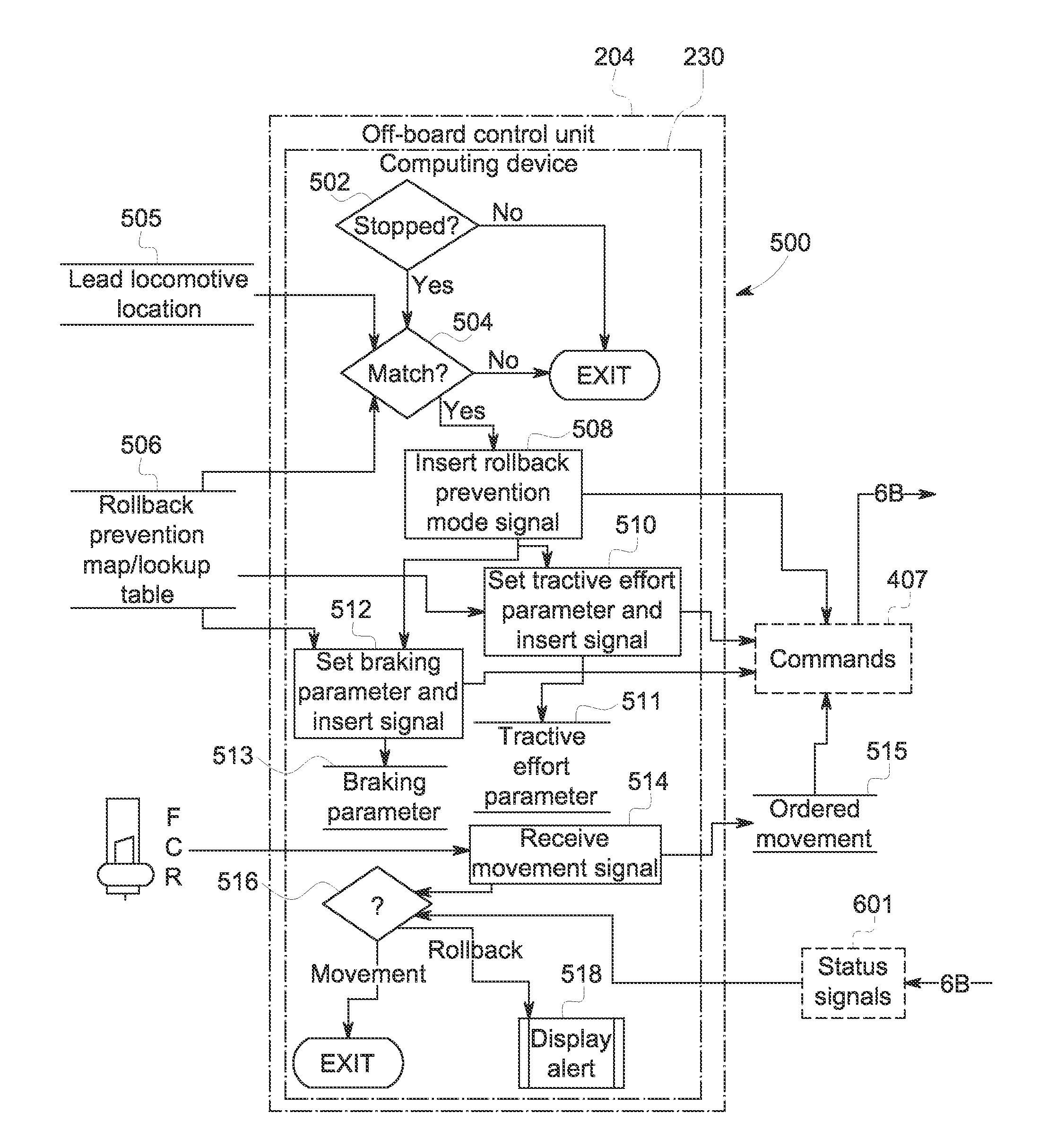

[0020]Reference will be made below in detail to exemplary embodiments of the invention, examples of which are illustrated in the accompanying drawings. Wherever possible, the same reference characters used throughout the drawings refer to the same or like parts. Although exemplary embodiments of the present invention are described with respect to rail vehicles within a rail yard, embodiments of the invention are also applicable for use with rail vehicles, generally.

[0021]FIG. 1 shows in schematic view a bulk cargo loading / unloading operation 10 that includes a loop (or other section) of track 12 connected from a main rail line 14 through loading / unloading equipment 16. In the loading / unloading equipment 16, coal / iron ore / other bulk products are dumped into or out of cars or wagons 18 of a train or other rail vehicle consist 20 that is located at a location on the loop of track 12. (A rail vehicle consist is a group of rail vehicles that are mechanically linked to travel together alo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com