Granules of graphene oxide by spray drying

a technology of graphene oxide and granules, which is applied in the field of granules of graphene oxide, can solve the problems of increasing the degree and complexity of corrugation, and achieve the effects of reducing graphene oxide, increasing the degree and complexity of corrugation, and reducing surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

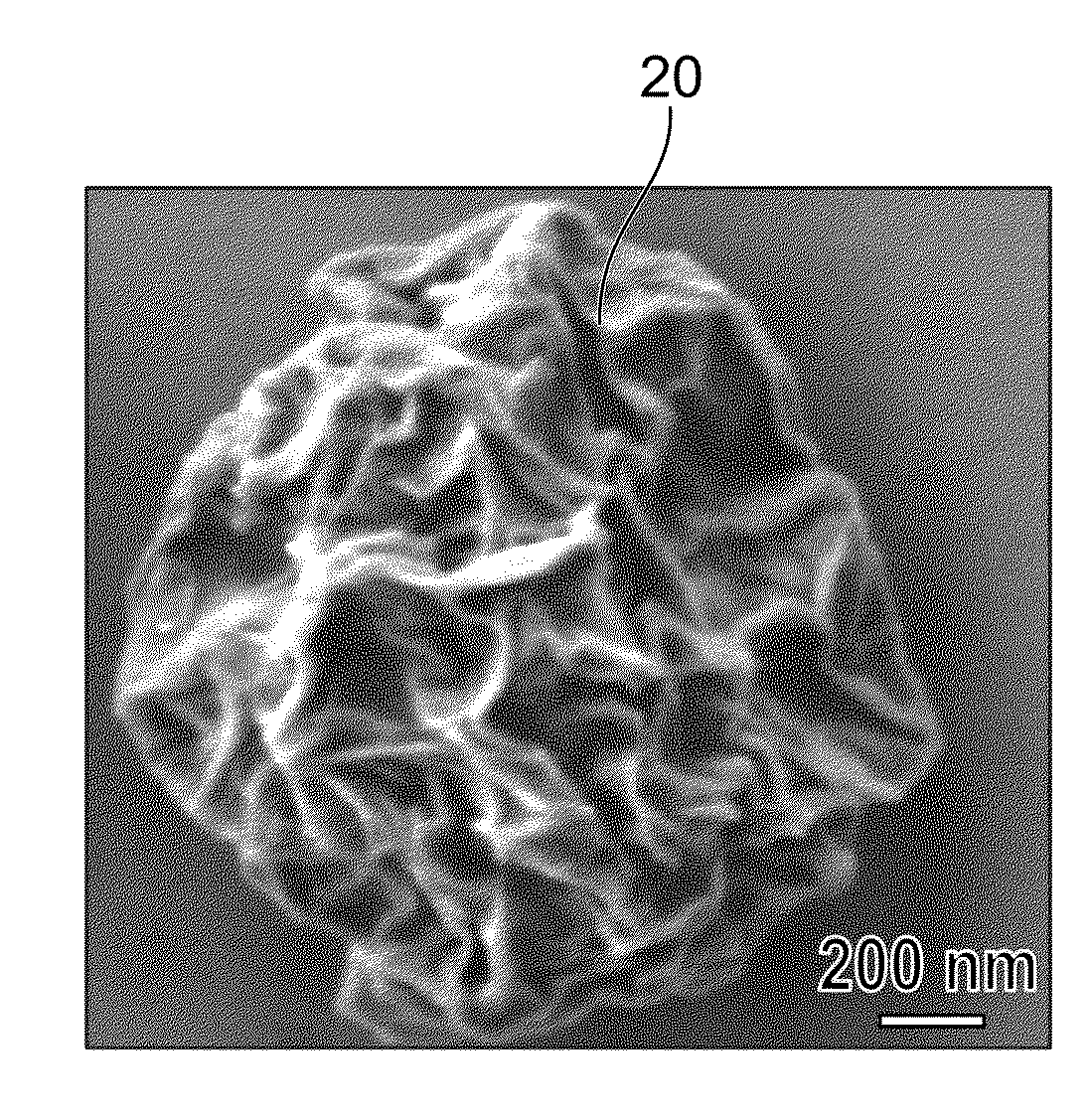

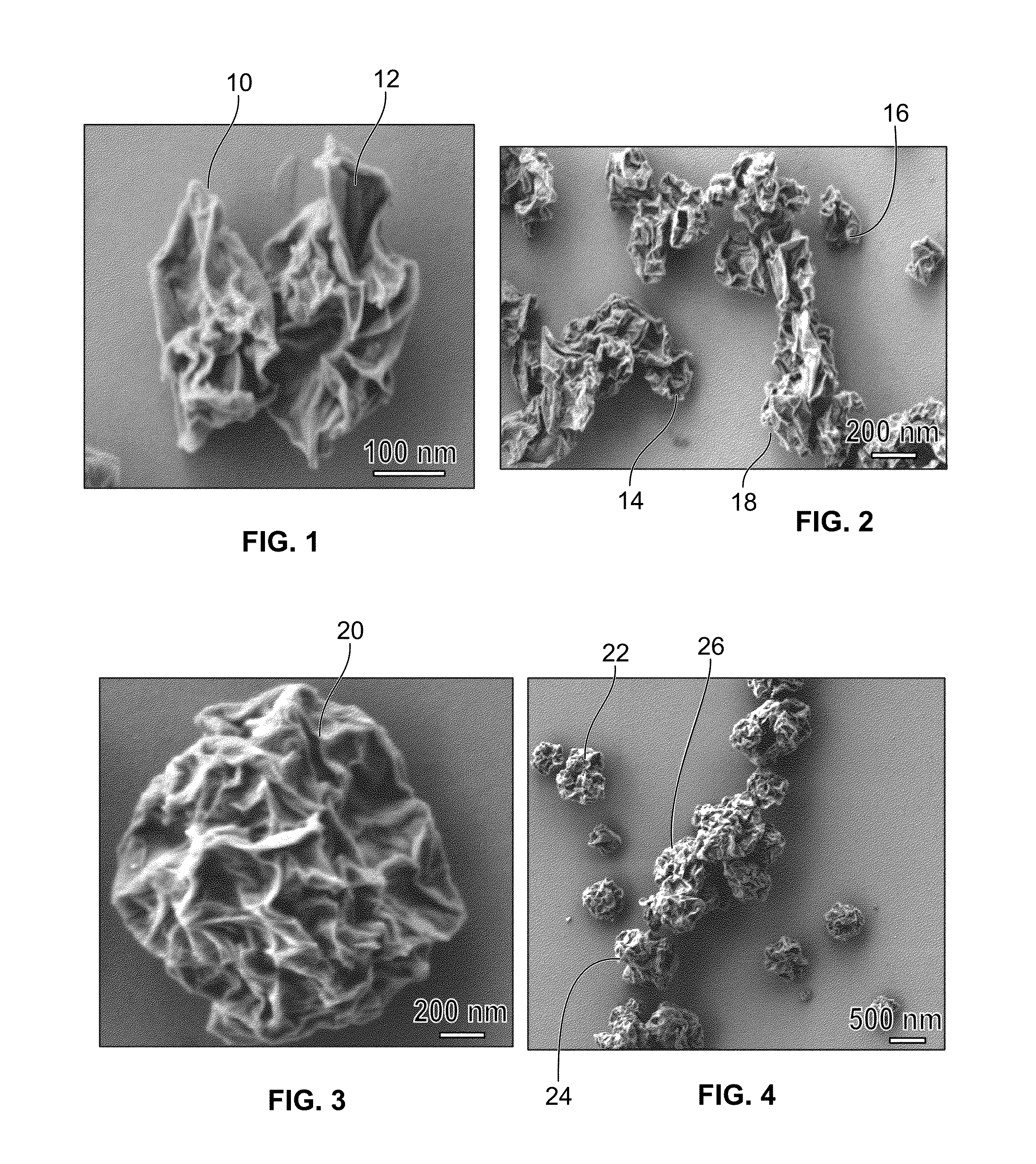

[0019]The present invention includes a method of making granules of graphene oxide having a three-dimensional corrugated morphology, which includes a step of spray drying a graphene oxide dispersion. In some embodiments of the invention, a suitable graphene oxide dispersion is prepared by dispersing graphite oxide solid into a solvent under ultrasonic conditions to form a stable dispersion of single molecular layers of graphene oxide. In some embodiments of the invention, the nanosheets of graphene oxide have a thickness of one to a few molecular layers and lateral dimensions of about 100 nm to about 1000 nm (1 μm). In other embodiments of the present invention, graphene oxide dispersions prepared by other means, or having graphene oxide sheets with other thicknesses or other nanoscale or microscale lateral dimensions may be used.

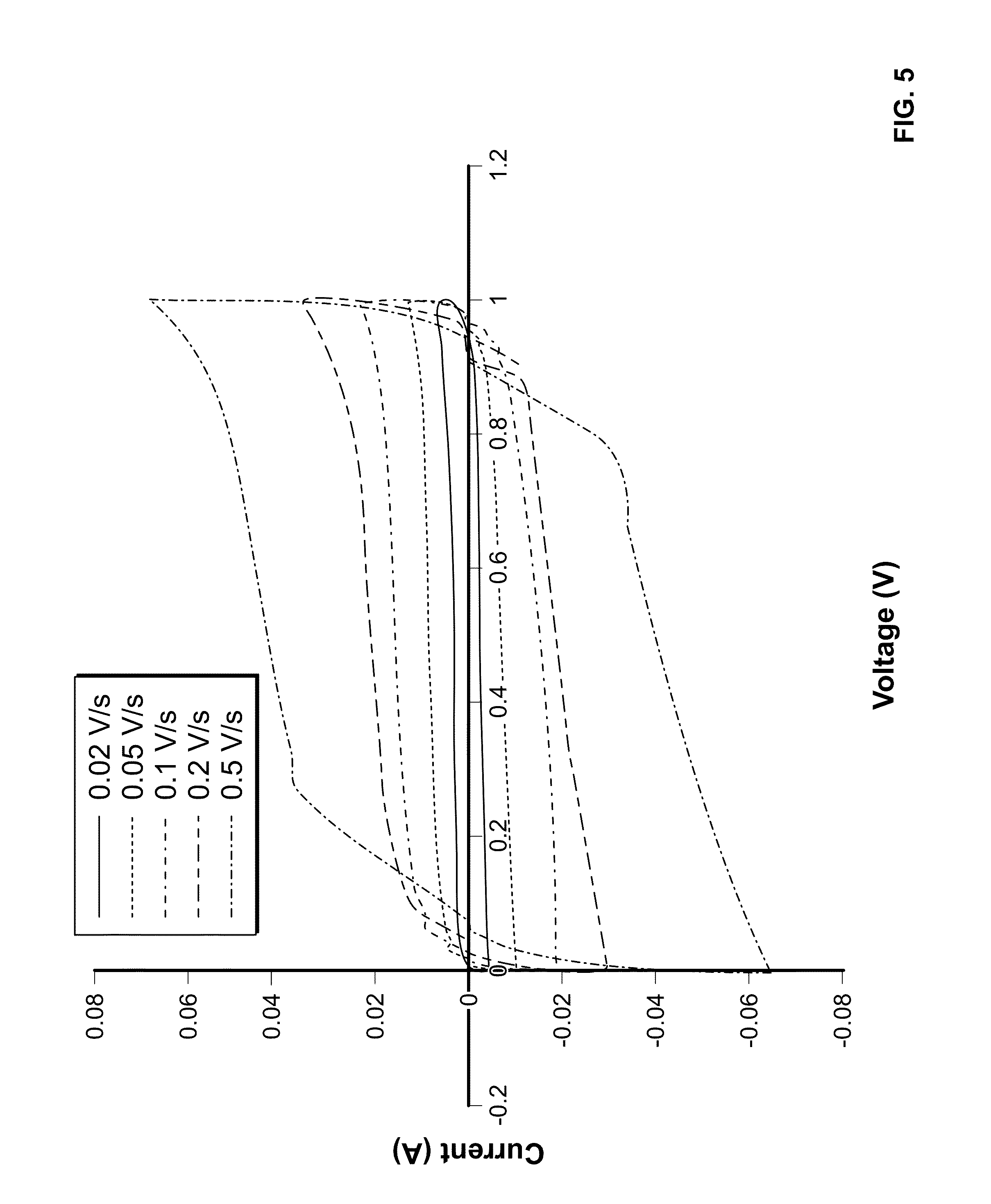

[0020]In an embodiment of a method of the present invention, a graphene oxide dispersion is spray dried using, for example, a commercial spray dryer to pro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Nanoscale particle size | aaaaa | aaaaa |

| Nanoscale particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com