Sealant laminated composite, sealed semiconductor devices mounting substrate, sealed semiconductor devices forming wafer, semiconductor apparatus, and method for manufacturing semiconductor apparatus

a technology of laminated composite and semiconductor devices, which is applied in the direction of transportation and packaging, water-setting substance layered products, synthetic resin layered products, etc., can solve the problems of reducing the reliability of the semiconductor apparatus, and achieve the effects of preventing the peeling of the semiconductor device, excellent sealing characteristics, and suppressing contraction stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

synthesis example 1

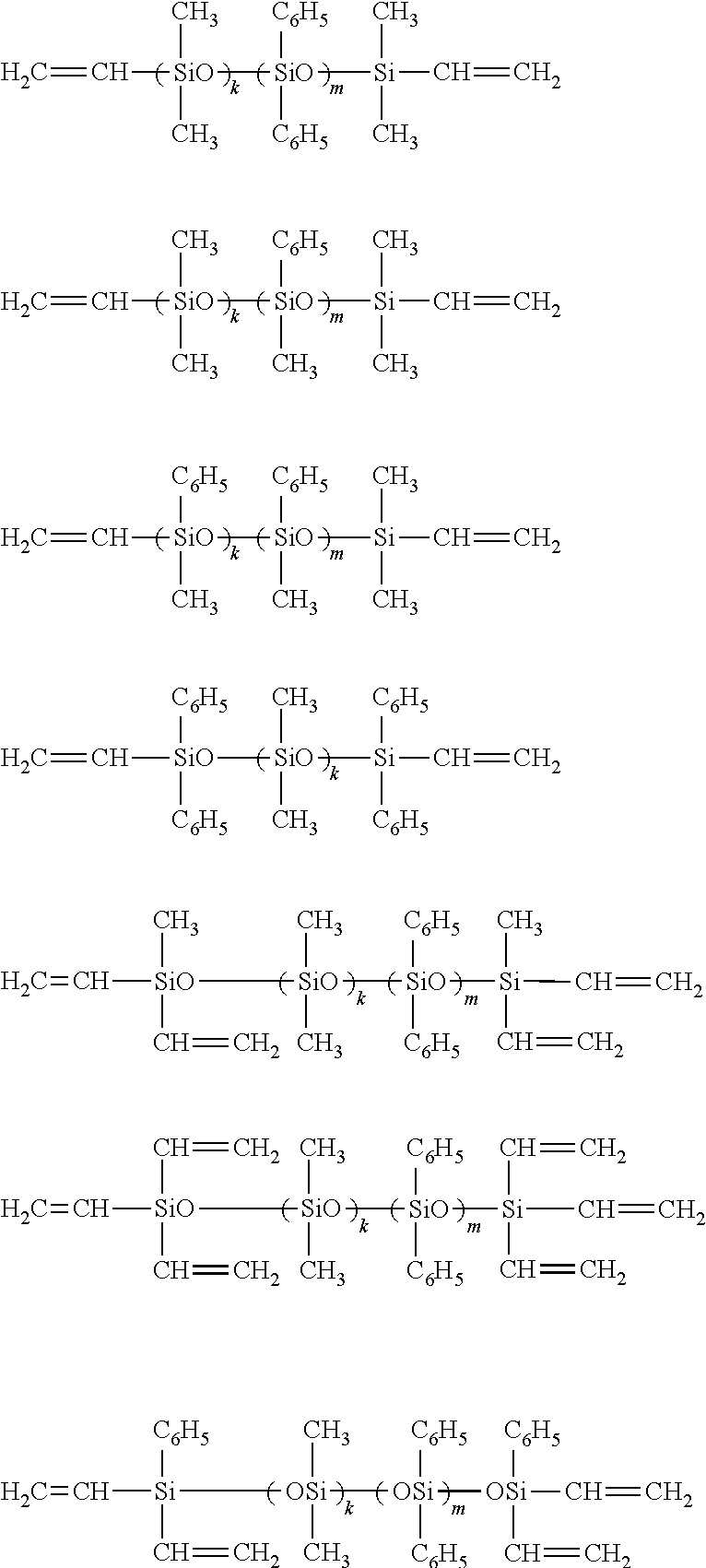

Organosilicon Compound Having Non-Conjugated Double Bond (A1)

[0128]To synthesize an organosilicon compound having a non-conjugated double bond (A1), 27 mol of organosilane represented as PhSiCl3, 1 mol of ClMe2SiO(Me2SiO)33SiMe2Cl, and 3 mol of MeViSiCl2 were dissolved in a toluene solvent, dropped into wafer, co-hydrolyzed, rinsed, neutralized by alkali cleaning, and dehydrated, and then the solvent was stripped. A composition ratio of constituent units of this compound is represented by an expression: [PhSiO3 / 2]0.27[—SiMe2o-(Me2SiO)33—SiMe2O—]0.01[MeViSiO2 / 2]0.03. A weight-average molecular weight of this compound was 62,000, and a melting point thereof was 60° C. It is to be noted that Vi in the composition formula represents a vinyl group represented by (—CH═CH2), and Me, Ph respectively represent a methyl group and a phenyl group (hereinafter, the same as the above).

Synthesis of Organohydrorgenpolysiloxane

synthesis example 2

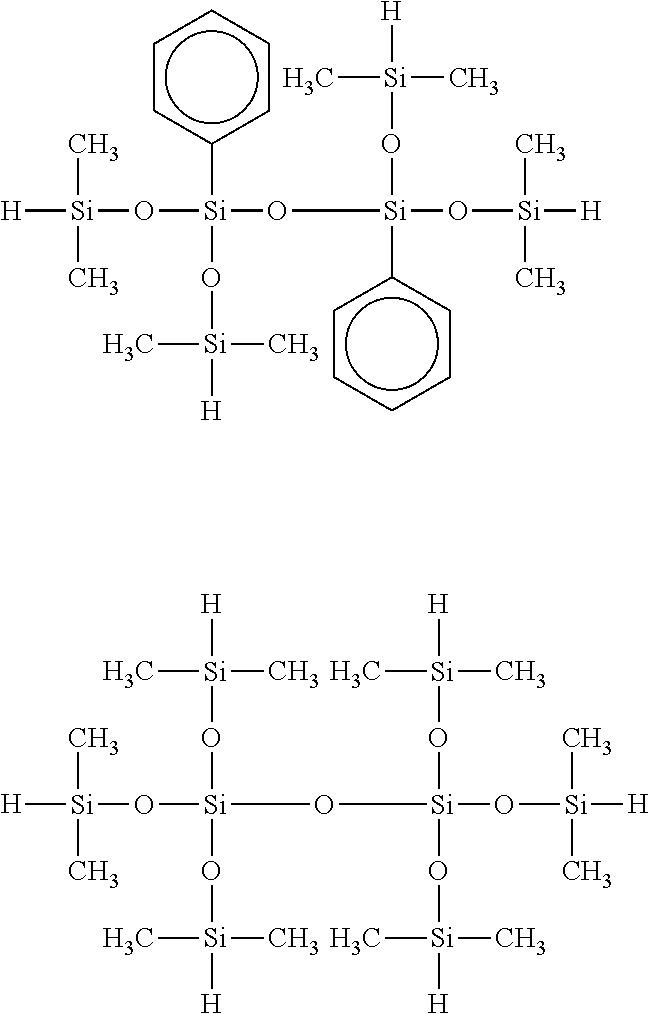

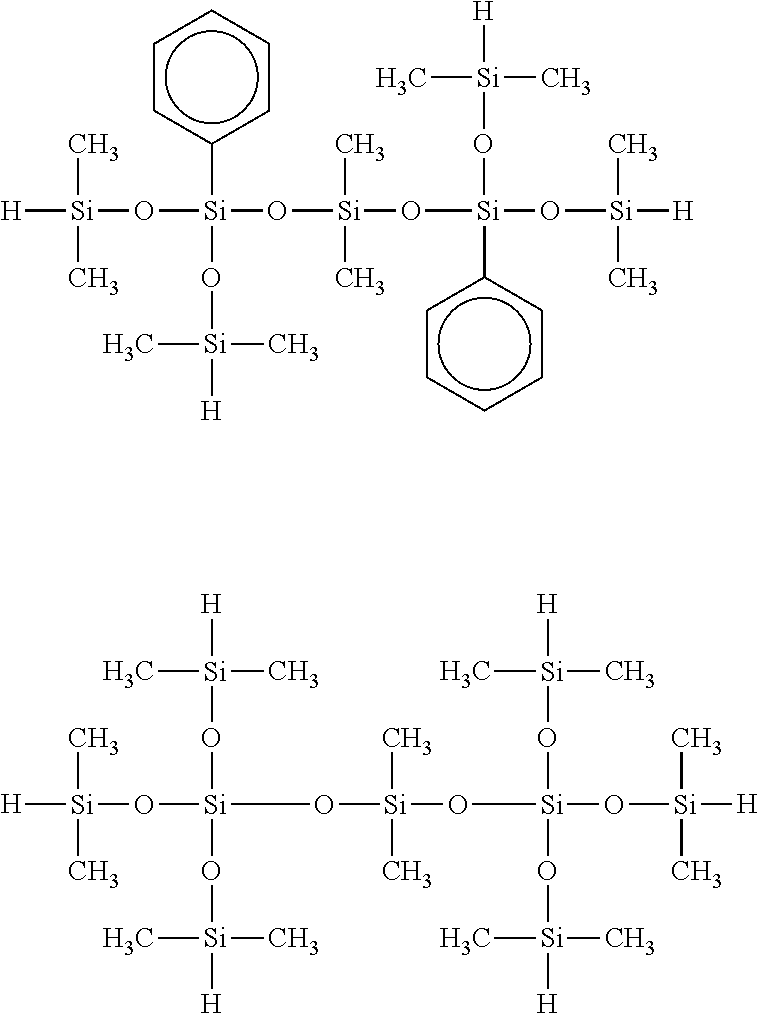

Organohydrogenpolysiloxane (B1)

[0129]To synthesize an organohydrorgenpolysiloxane (B1), 27 mol of organosilane represented as PhSiCl3, 1 mol of ClMe2SiO(Me2SiO)33SiMe2Cl, and 3 mol of MeHSiCl2 were dissolved in a toluene solvent, dropped into wafer, co-hydrolyzed, rinsed, neutralized by alkali cleaning, and dehydrated, and then the solvent was stripped. A composition ratio of constituent units of this resin is represented by an expression: [PhSiO3 / 2]0.27[—SiMe2O-(Me2SiO)33—SiMe2O—]0.01[MeHSiO2 / 2]0.03. A weight-average molecular weight of this compound was 58,000, and a melting point of the same was 58° C.

example 1

Fabrication of Composition for Forming Uncured Resin Layer Constituted of Uncured Thermosetting Resin

[0130]With respect to a composition in which 50 parts by mass of the organosilicon compound having a non-conjugated double bond (A1), 50 parts by mass of organohydrogenpolysiloxane (B1), 0.2 parts by mass of acetylene alcohol-based ethynylcyclohexanol as a reaction inhibitor, and 0.1 parts by mass of an octyl alcohol-modified solution of a chloroplatinic acid were added, 350 parts by mass of spherical silica having an average particle size of 5 μm were added at 60° C. and well agitated by a planetary mixer heated to 60° C. to fabricate a silicone resin composition (I-a). The composition was solid at room temperature (25° C.)

[Fabrication of Sealant Laminated Composite]

[0131]The silicone resin composition (I-a) was sandwiched between a silicon wafer (support wafer) having a diameter of 300 mm (12 inches) and a fluororesin-coated PET film (release film) and compression molded for 5 min ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com