Exhaust purification system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

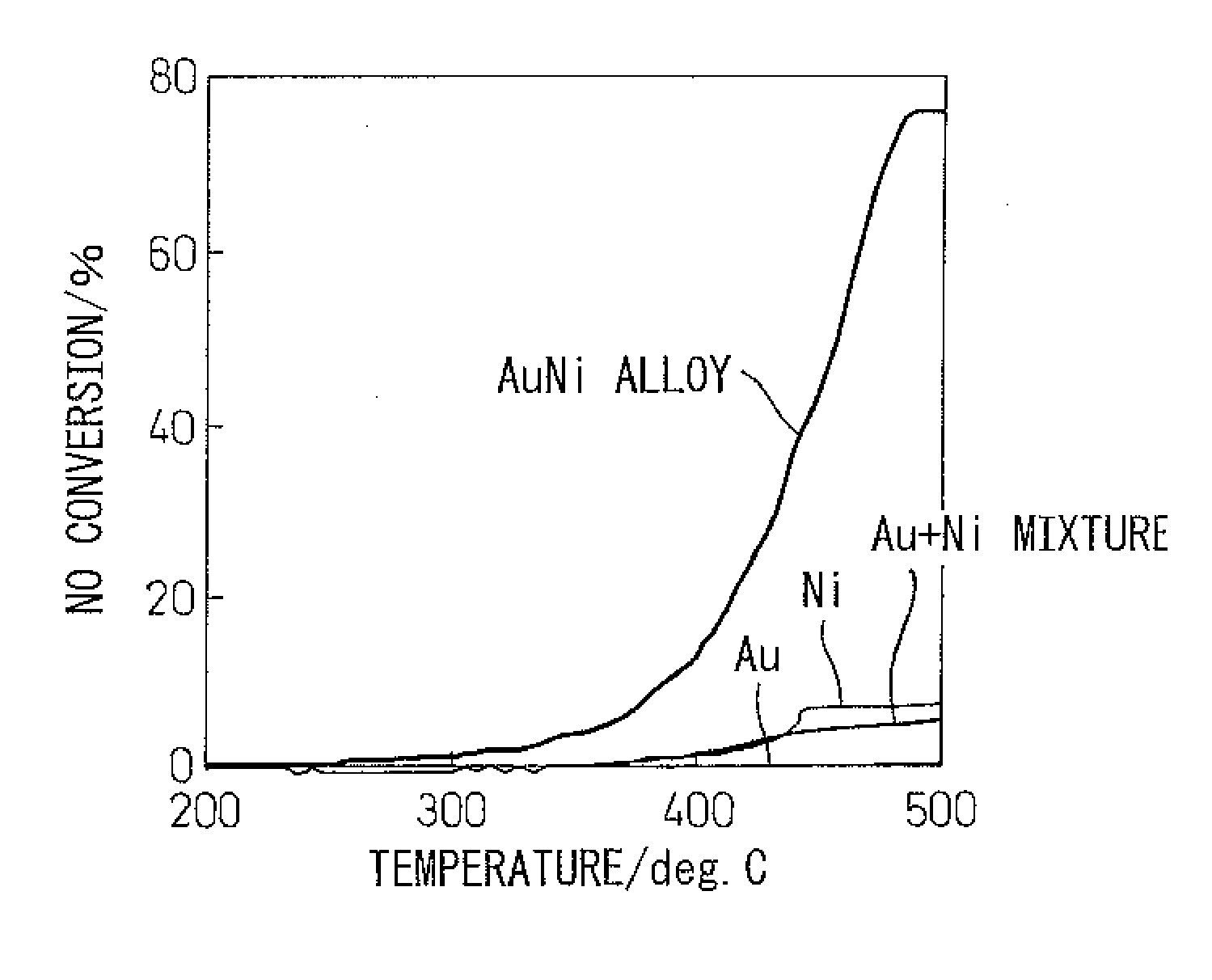

reference example 1

1) Synthesis of AuNi Nanoparticles

[0046]In a two-necked flask, 1.1 g of poly-n-vinylpyrrolidone (PVP) was added to 120 ml of anhydrous ethylene glycol. Into this mixture, 0.1404 g of nickel sulfate was added. The mixture was agitated at 80° C. for 3 hours to obtain a solution (solution 1). Separately, in a two-necked flask, 0.1809 g of NaAuCl4 was added to 50 ml of distilled water. The mixture was strongly agitated for 2 hours or more to cause dissolution and obtain a bright red colored solution (solution 2). The solution 1 was cooled by a cooling bath down to 0° C., then the solution 2 was poured into the solution 1 in the flask and the two were uniformly agitated. The mixed solution was adjusted by a 1M NaOH solution (about 5 ml) to give a pH of 9 to 10. The mixed solution was heated by an oil bath to 100° C. and was held for 2 hours while being agitated. After this, the flask was lifted up from the oil bath and allowed to stand until the colloidal suspension was cooled to room te...

reference example 2

[0058]Except for changing the carrier particles from Al2O3 to CeO2—ZrO2(CZ), the same procedure was followed as in Reference Example 1 to obtain an AuNi(50:50) / CZ catalyst. The obtained AuNi(50:50) / CZ catalyst was measured for shape and particle size distribution of the alloy particles and analyzed by elementary analysis by TEM and TEM-EDS. The nanoparticles had a size of 3.61 nm±0.9 nm. Further, from the TEM-EDS spectrum measured for the AuNi(50:50) colloid on the Cu covered grid, all of the individual particles contained Au and Ni. Further, the obtained AuNi(50:50) / CZ catalyst was measured for catalytic activity under the following conditions and various gas flow conditions.

[0059]Space Velocity (SV): 100000 (0.6 g, 1 L / min)

[0060]All conditions are stoichiometry, N2 balance

[0061]The O2, H2 treatment is performed under 500° C. before the catalytic activity test

Gas Flow Conditions

[0062](1) NO: 3000 ppm, CO: 3000 ppm

[0063](2) NO: 1500 ppm, CO: 6500 ppm, O2: 7000 ppm, C3H6: 1000 ppm

[00...

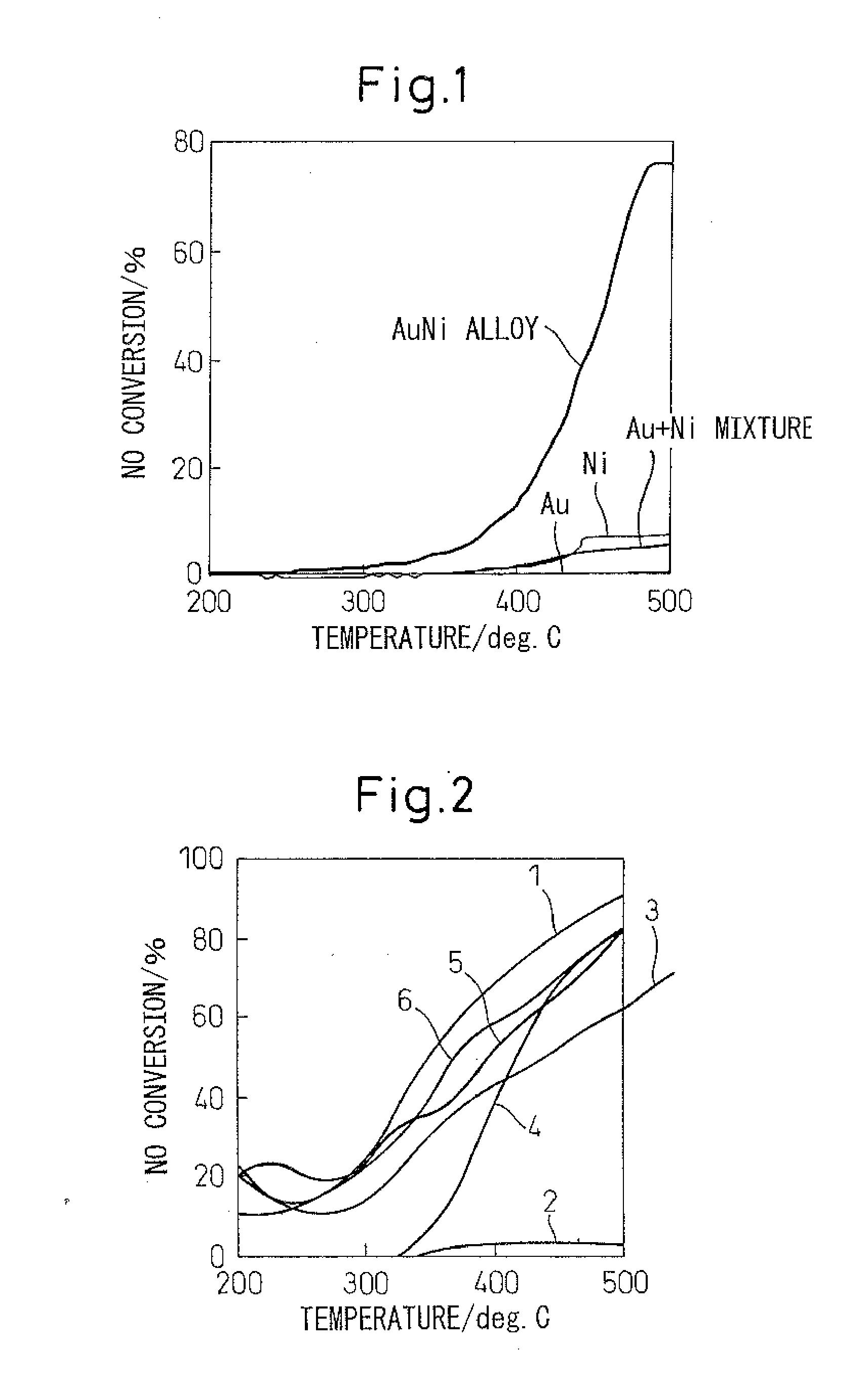

examples 1 to 2

[0069]In the apparatus used for measurement of the catalytic activity described above, as the HC oxidation catalyst, Pd / CeO2 prepared by an ordinary method (Example 1) or Ag / Al2O3 prepared by an ordinary method (Example 2) was placed upstream of the NOX purification catalyst. As the NOX purification catalyst, the AuNi(50:50) / CZ catalyst obtained in Reference Example 2 was used to prepare the exhaust gas purification system. This exhaust gas purification system was fed with gas of the gas composition (2) to purify the exhaust gas and obtain NO purification characteristics the same as the curve shown by the curve 5 of FIG. 2. The above results show that according to the exhaust gas purification system of the present invention, the NO purification characteristics are greatly improved from the curve 2 to the curve 5 of FIG. 2.

[0070]According to the exhaust purification system of the present invention, from the viewpoint of resource depletion, by using an NOX purification catalyst using ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com