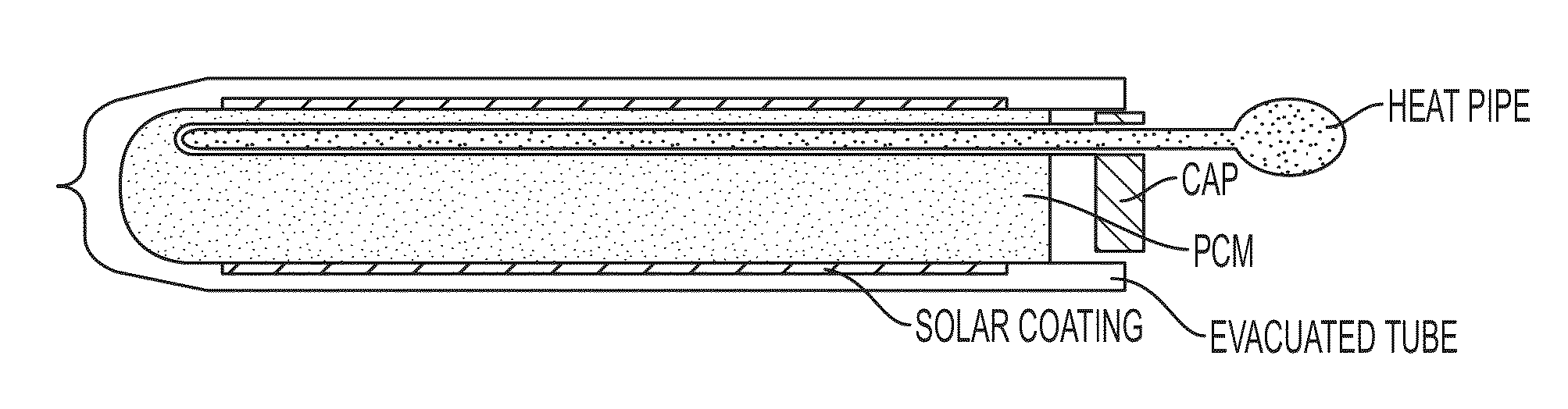

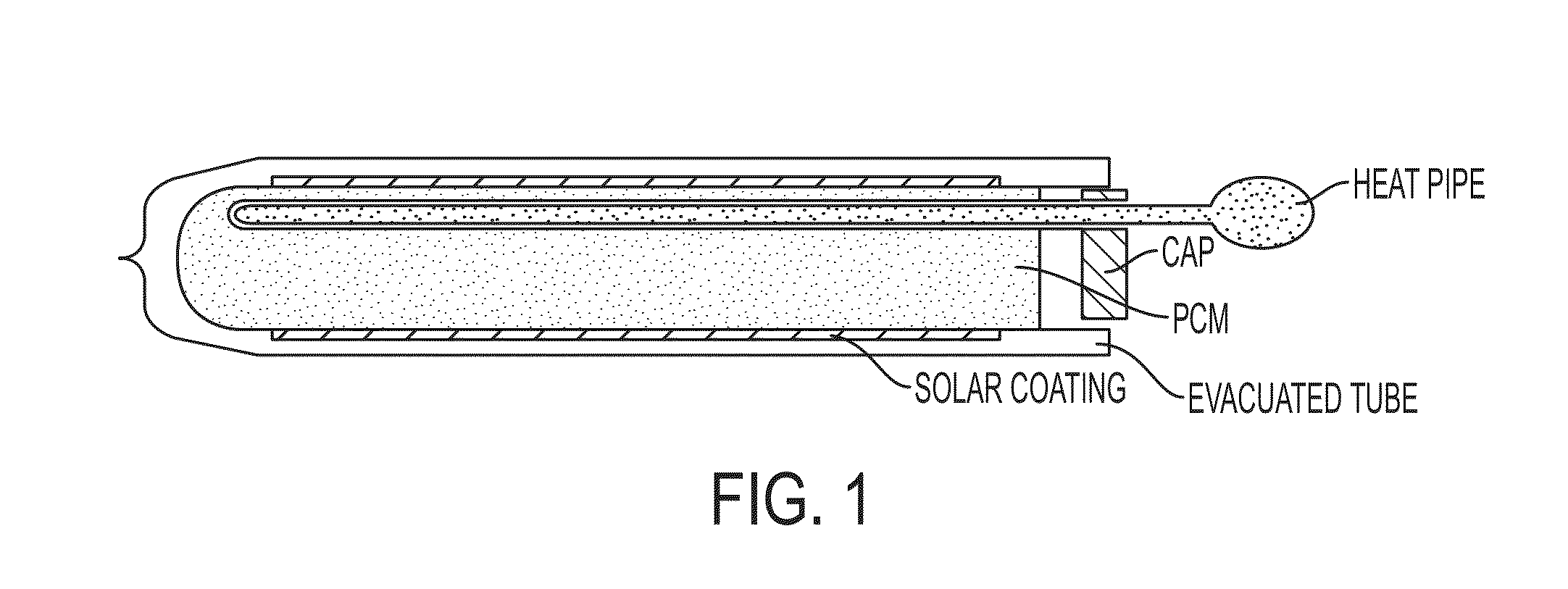

Integration of phase change materials inside evacuated tube solar collector for storage and transfer of thermal energy

a solar collector and phase change technology, applied in solar heat storage, solar heat reduction, lighting and heating apparatus, etc., can solve the problems of increasing the thermal conductivity of the pcm, not all pcms are ideal for our novel idea, and low thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

Performance of Evacuated Tube Collector Systems Filled with Phase Change Materials

[0033]In order to evaluate the performance of phase change material inside evacuated tube collector, field test on 0.5 meter collectors were carried out. FIG. 7 shows curves of the temperature inside the tube in three different cases. Two paraffin based PCM materials with different working temperatures (56° C. and 73° C.) were added inside the tube collector are compared to a standard tube collector. Also, erythritol was used for comparison with paraffin PCM. The temperature of metal fins of ETC was measured after exposure to sun for 3 hours and during the cool down in the shade. A small water tank (600 ml) was placed on top of heat pipe. In the case of the 56° C. PCM filled tube; we observe a significantly faster cooling rate. In the case of paraffin 73° C. the temperature inside the tube remains higher that paraffin 56° C. In FIG. 8 we show the recorded temperatures inside small water tank on the top...

example 2

On-Demand Operation of Evacuated Tube Collector SWH System Filled with Phase Change Material

[0035]In FIG. 10 we report results recorded during cool down of systems. Initially, both solar collectors were kept in stagnation mode, i.e. without a water flow through heat exchanger. A few seconds before systems being covered from sunlight, water flow started with the rate of at 0.2 GPM.

[0036]We observe the temperature inside evacuated tubes to be significantly higher compared to operation in normal mode, since no heat transfer to water is possible. We can assume that phase change of paraffin has occurred for the majority of the material since the temperature inside the tubes with paraffin has exceeded 73° C. We observe the fast cool down of standard evacuated tube (∘) and the delayed cool down of PCM tubes (). While systems are stagnated, the majority of absorbed energy is accumulated in PCM materials. Once the water flow is started, the energy can be transferred to water through the hea...

example 3

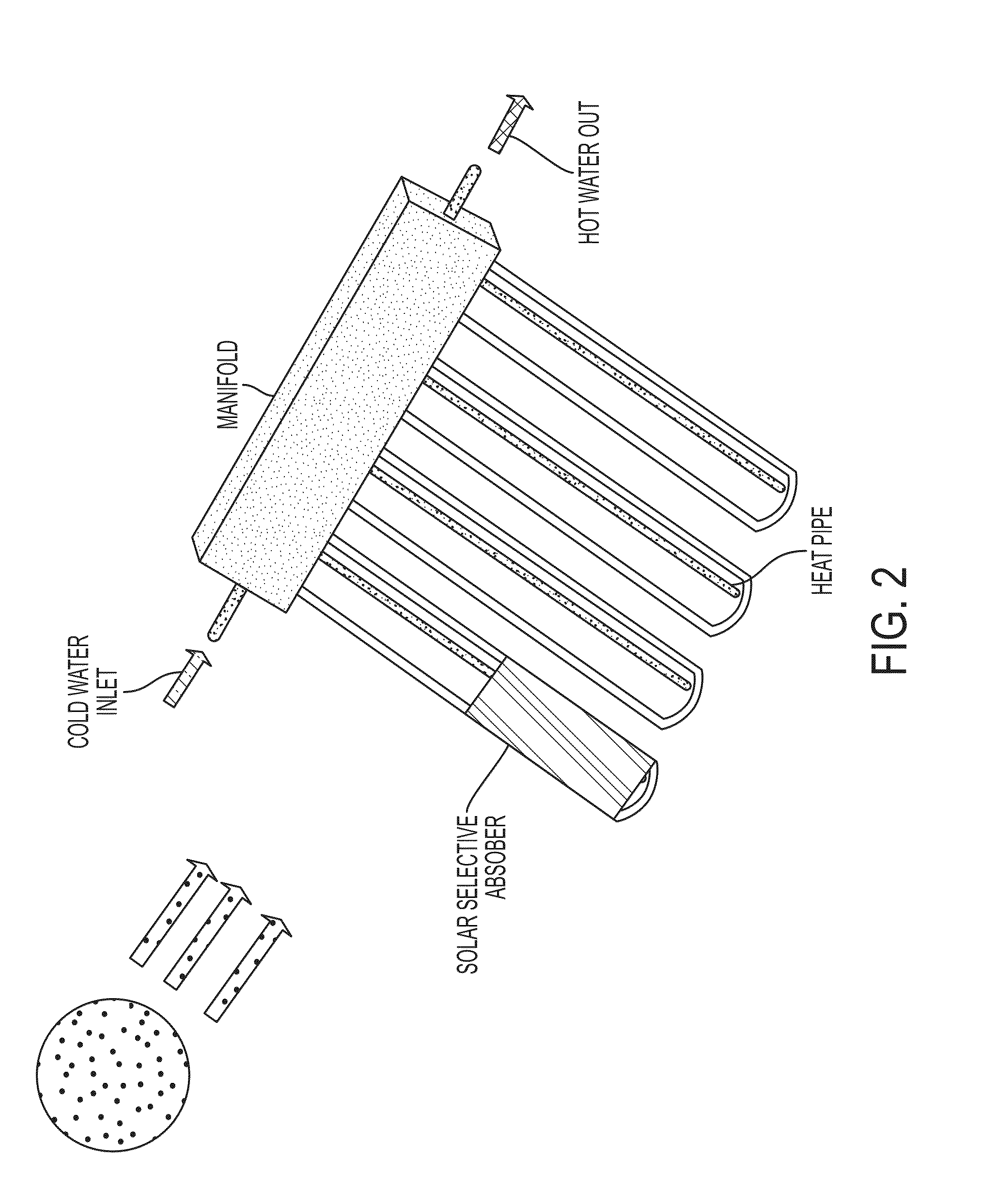

Operation of ETC Solar Collector Assemblies with PCM

[0038]Two systems (typical ETC system and PCM integrated system) were operated daily under similar conditions. The solar water heaters were operated in two different modes, first in normal operation the water is circulated between the manifold of the collector at a constant flow rate and the water tank. Second, in stagnation mode, no water flow was initiated through the manifold for an extended time and the pump was not started until PCM in both systems was melted and collectors have been covered completely from sun. The temperatures of water in the storage tank of a typical solar water system and a PCM integrated systems are shown in FIG. 12 for normal operational mode. In all cases the temperature appears peak at time the systems are covered, where the temperature in tank of system without PCM cools down rapidly. In contrast, the tank of paraffin filled system shows a slower cooling rate and the significant heat loss from uninsul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com