Systems and methods for protecting a turbocharger aluminum bearing housing

a technology for aluminum bearings and turbochargers, which is applied in the direction of machines/engines, mechanical equipment, liquid fuel engines, etc., can solve the problems of increasing wear at the interface, increasing the efficiency of vehicles, and increasing the mass of vehicles, so as to facilitate the use of aluminum bearing housings, avoid wear and other issues, and improve heat resistan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

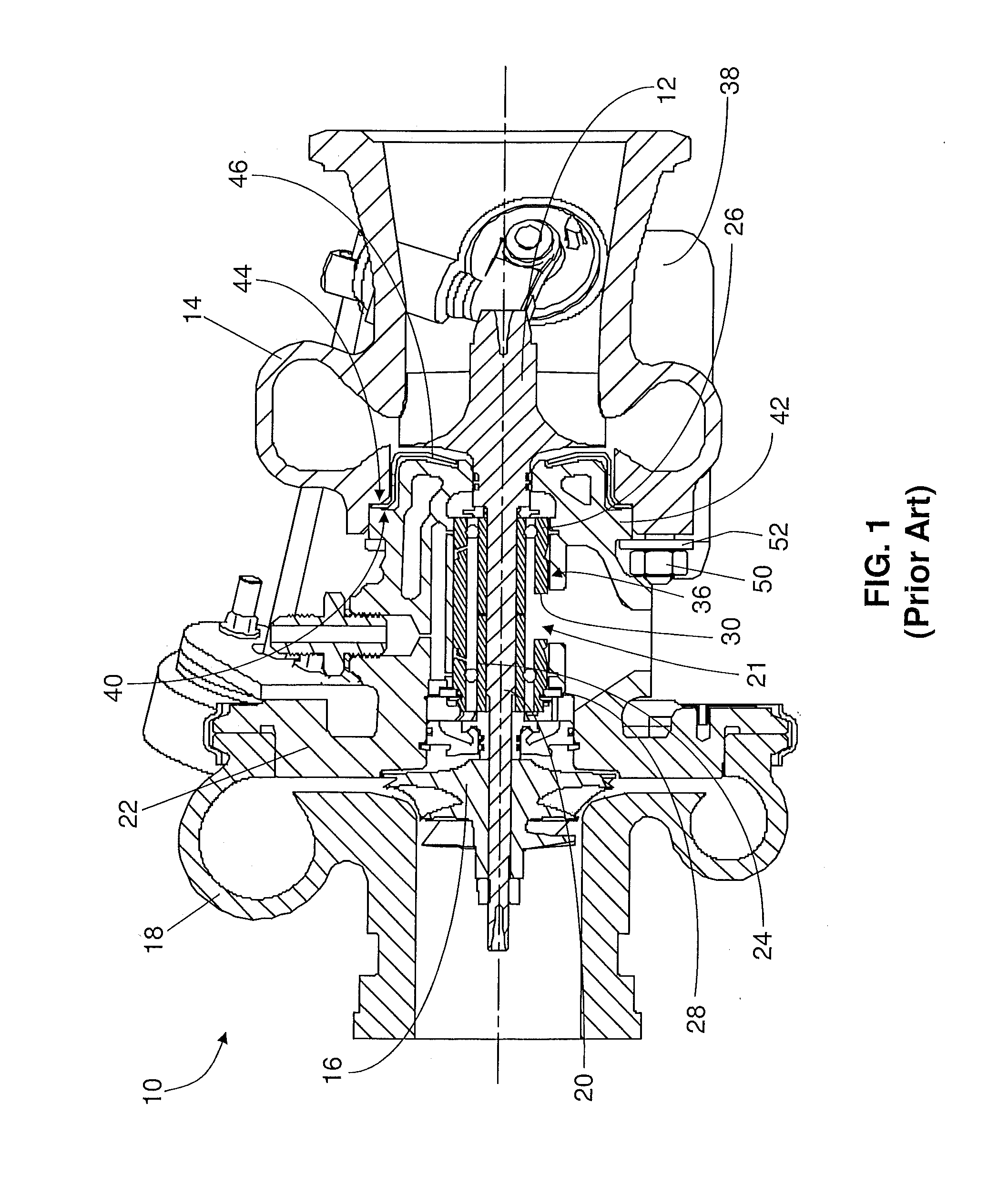

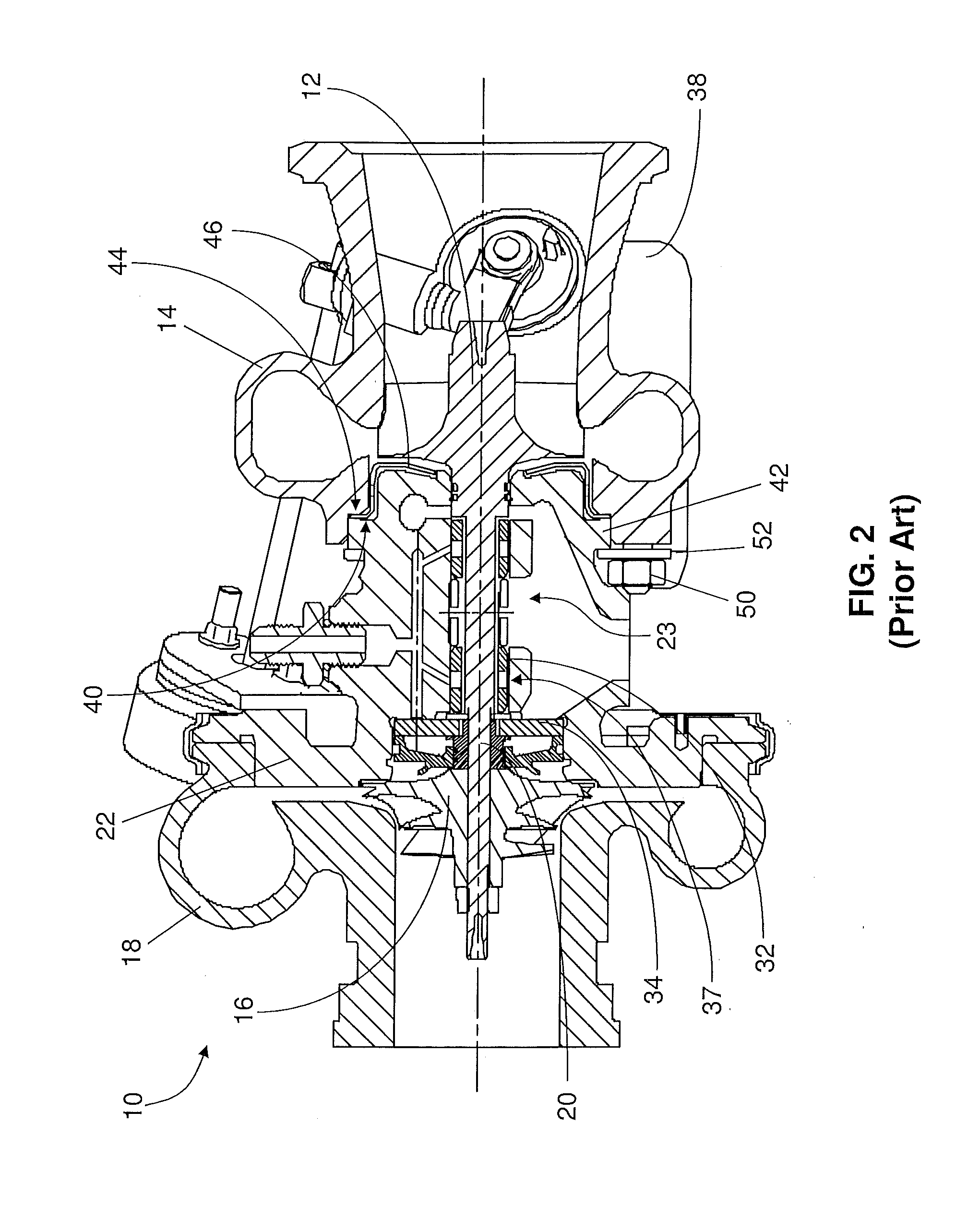

[0020]Arrangements described herein relate to device turbocharger with an aluminum bearing housing configured for improved interface with the turbine housing and / or bearing system. Detailed embodiments are disclosed herein; however, it is to be understood that the disclosed embodiments are intended only as exemplary. Therefore, specific structural and functional details disclosed herein are not to be interpreted as limiting, but merely as a basis for the claims and as a representative basis for teaching one skilled in the art to variously employ the aspects herein in virtually any appropriately detailed structure. Further, the terms and phrases used herein are not intended to be limiting but rather to provide an understandable description of possible implementations. Arrangements are shown in FIGS. 4-6, but the embodiments are not limited to the illustrated structure or application.

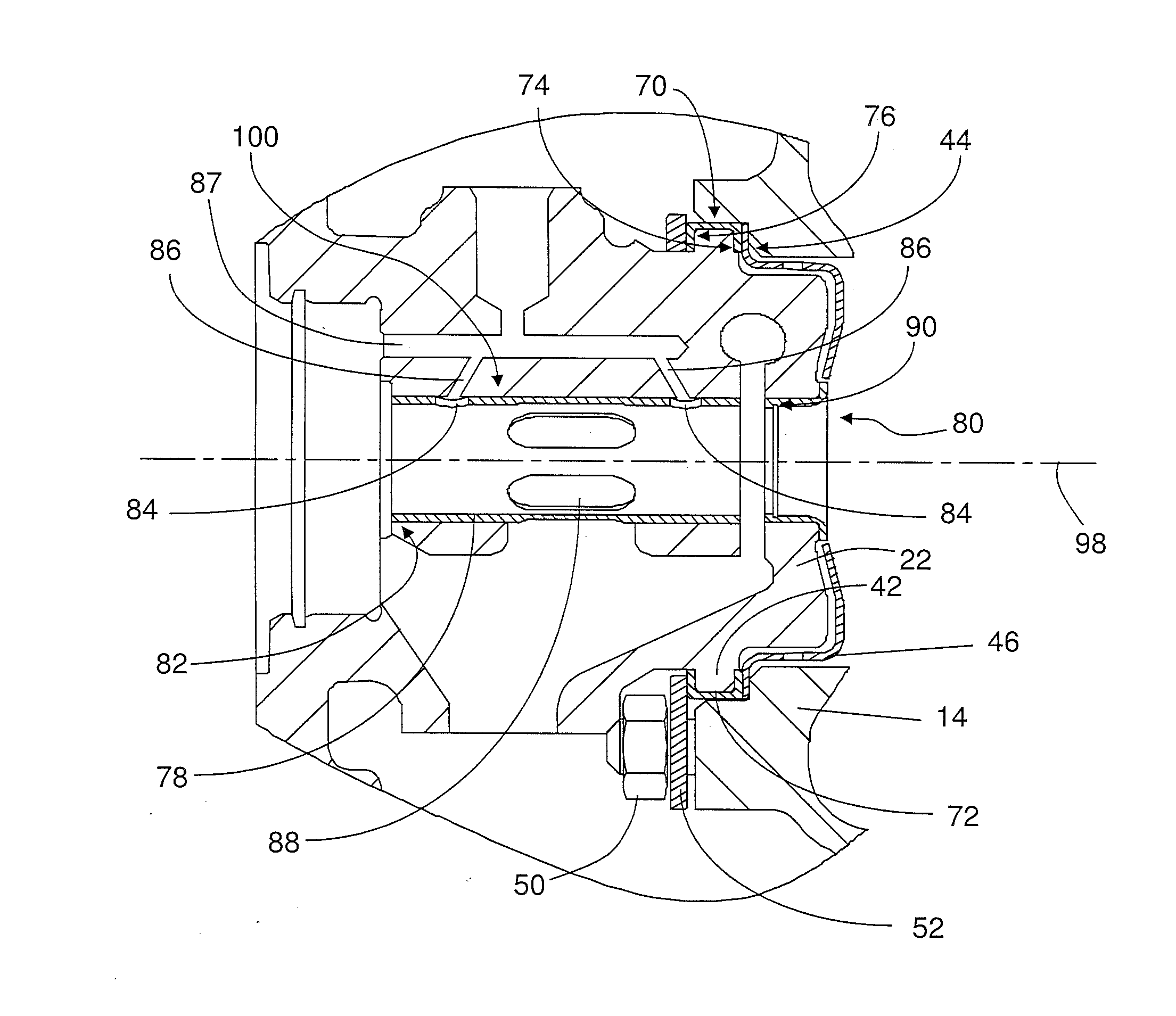

[0021]Referring to FIG. 4, examples of protective systems for an interface between an aluminum bearing...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperatures | aaaaa | aaaaa |

| heat resistance | aaaaa | aaaaa |

| wear resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com