Method for manufacturing a magnetic tape head using an ink mask formed by printing

a printing and ink mask technology, applied in the field of magnetic data recording, can solve the problems of increasing the loss of the wallace spacing, and increasing the spacing between the magnetically active portion of the sensor and the magnetic coating on the tape, so as to protect the tape from damage and corrosion without increasing the magnetic spacing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019]The following description is of the best embodiments presently contemplated for carrying out this invention. This description is made for the purpose of illustrating the general principles of this invention and is not meant to limit the inventive concepts claimed herein.

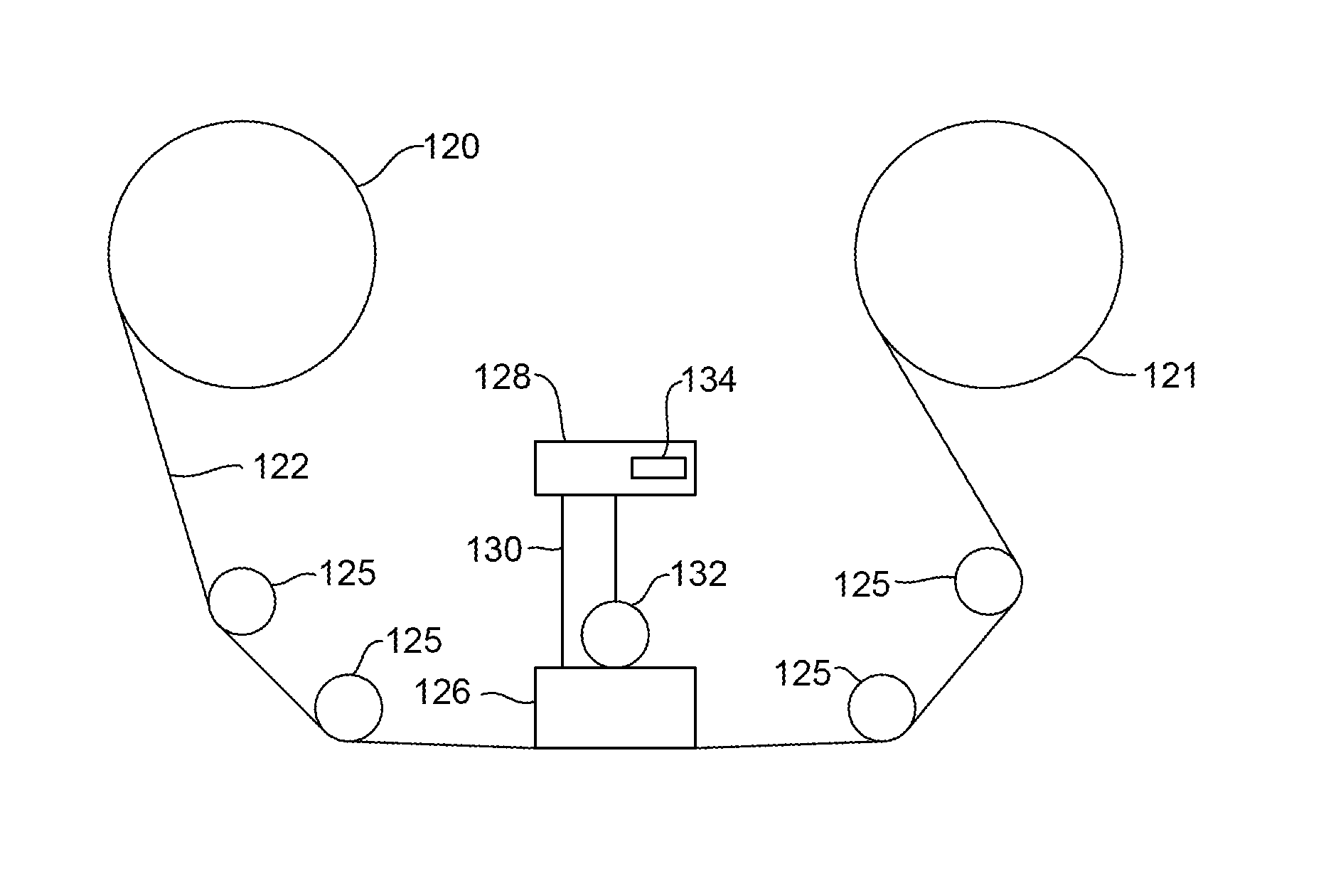

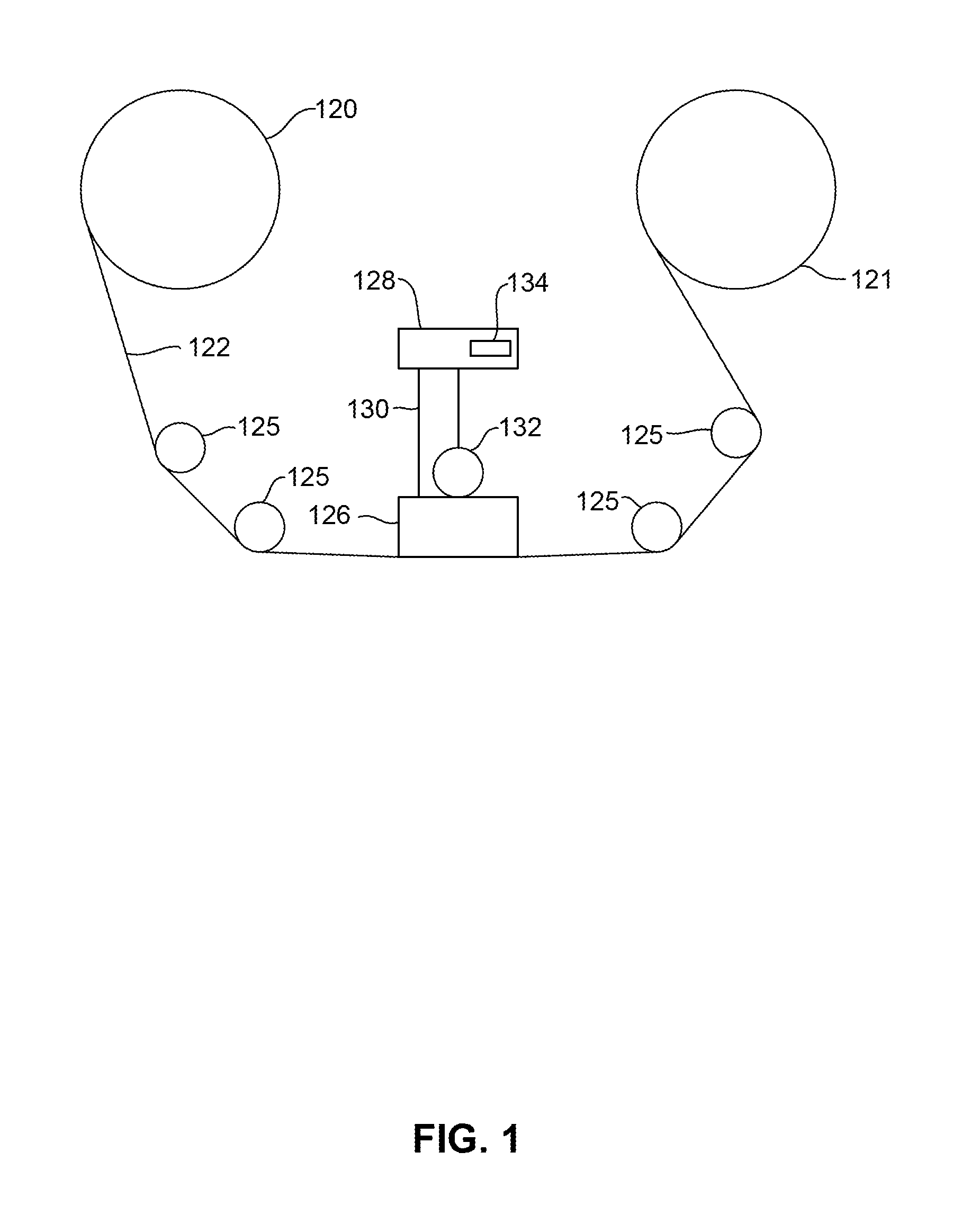

[0020]FIG. 1 is a schematic illustration of a tape drive 100 of a tape-based storage system. While one specific implementation of a tape drive is shown in FIG. 1, it should be noted that the embodiments describe herein may be implemented in the context of any type of tape drive system.

[0021]As shown, a tape supply cartridge 120 and a take-up reel 121 are provided to support a tape 122. One or more of the reels 121 may form a part of a removable cartridge and are not necessarily part of the system 100. The tape drive, such as that illustrated in FIG. 1, may further include drive motor(s) (not shown) to drive the tape supply cartridge 120 and the take-up reel 121 to move the tape 122 over a tape head 126 of any t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com