X-ray fluoroscopic imaging system

a fluoroscopic imaging and fluorescence technology, applied in the field of x-ray fluorescence imaging system, can solve the problems of limited penetration energy, low ray energy, limited volume of subject that can be checked, etc., and achieve the effects of low cost, simple structure and fast speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

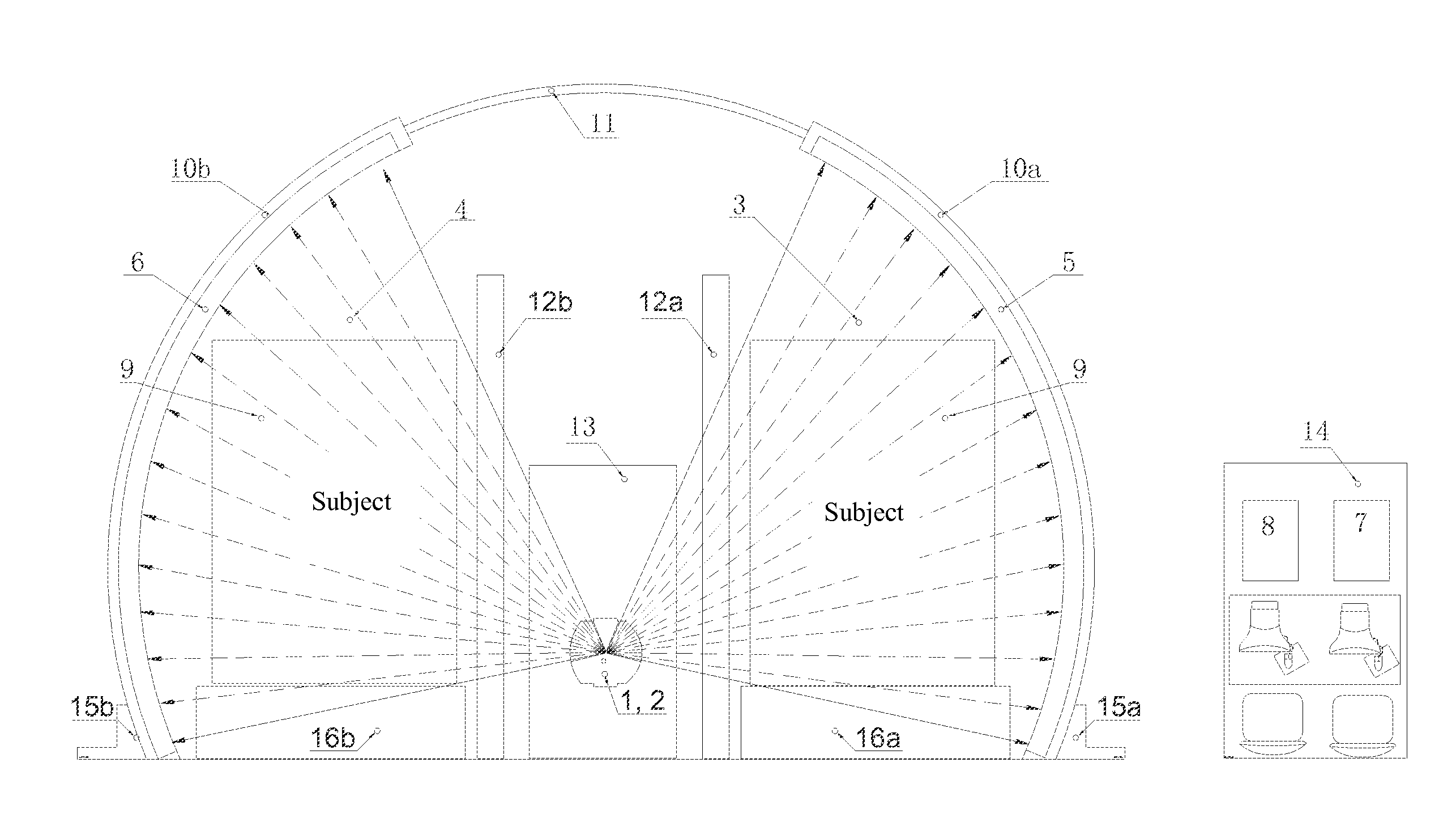

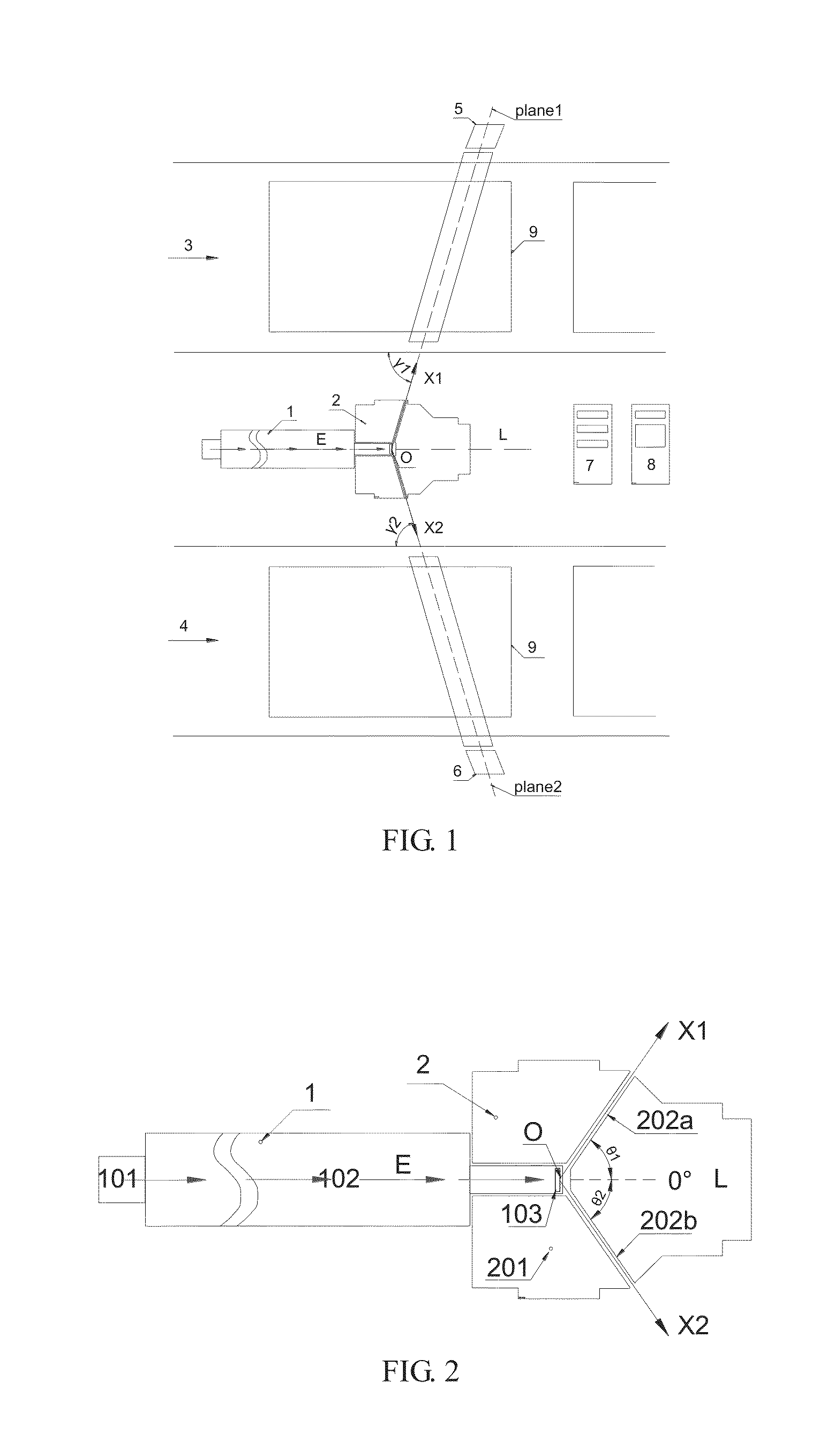

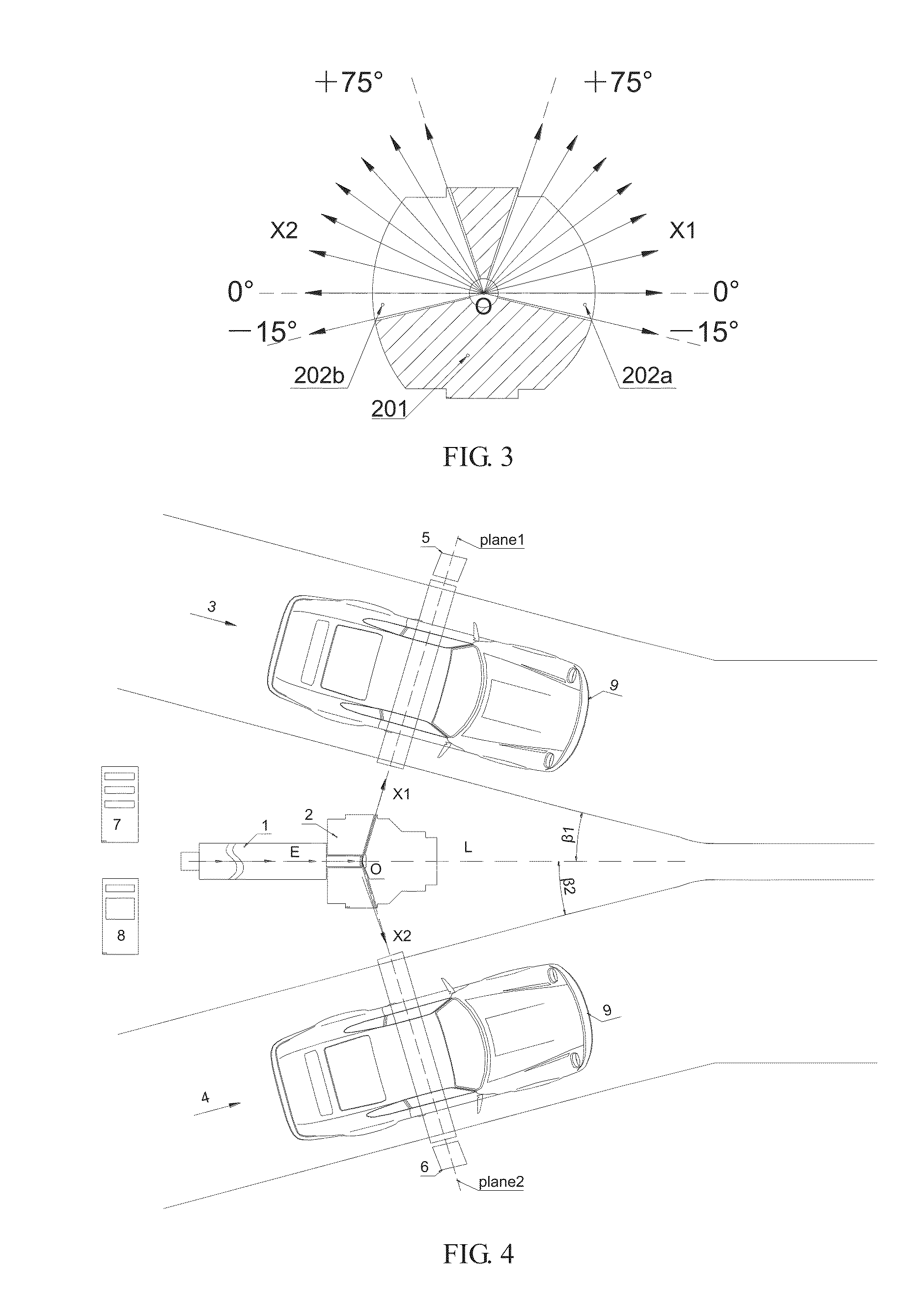

[0023]As shown in FIG. 1, FIG. 2 and FIG. 3, a dual-channel high-energy X-ray fluoroscopic imaging system comprises: an electron accelerator 1, a shielding and collimating device 2, a first inspection channel 3, a second inspection channel 4, a first detector array 5, a second detector array 6, a power supply and control subsystem 7, and a signal analysis and image processing subsystem 8. The high-energy electron accelerator 1 includes an electron emitting unit 101, an electron accelerating unit 102 and a target 103, and generates an electron beam E with energy above 2 Mev. The shielding and collimating device 2 includes a shielding structure 201 and at least two collimators 202a and 202b, and the two collimators are respectively disposed on both sides of the axis of the electron beam E. The first inspection channel 3 and the second inspection channel 4 are respectively located on both sides of the electron accelerator 1. The first collimator 202a, the first detector array 5 and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com