Multiple probe detection and actuation

a multi-probe, detection and actuation technology, applied in the field of multi-probe detection and actuation, can solve the problems of complex and corresponding cost of sensors, design flexibility, and layout redesign

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

)

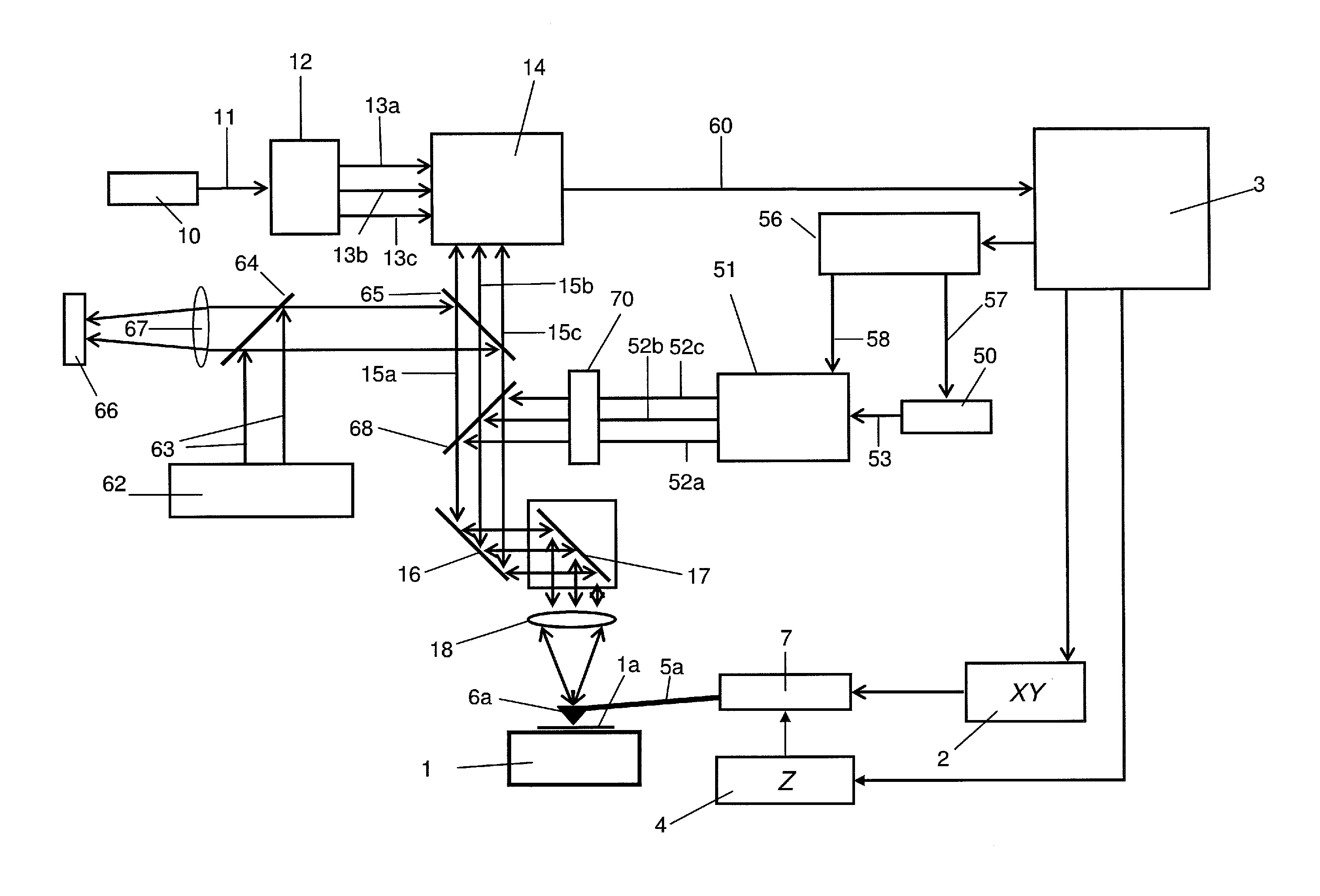

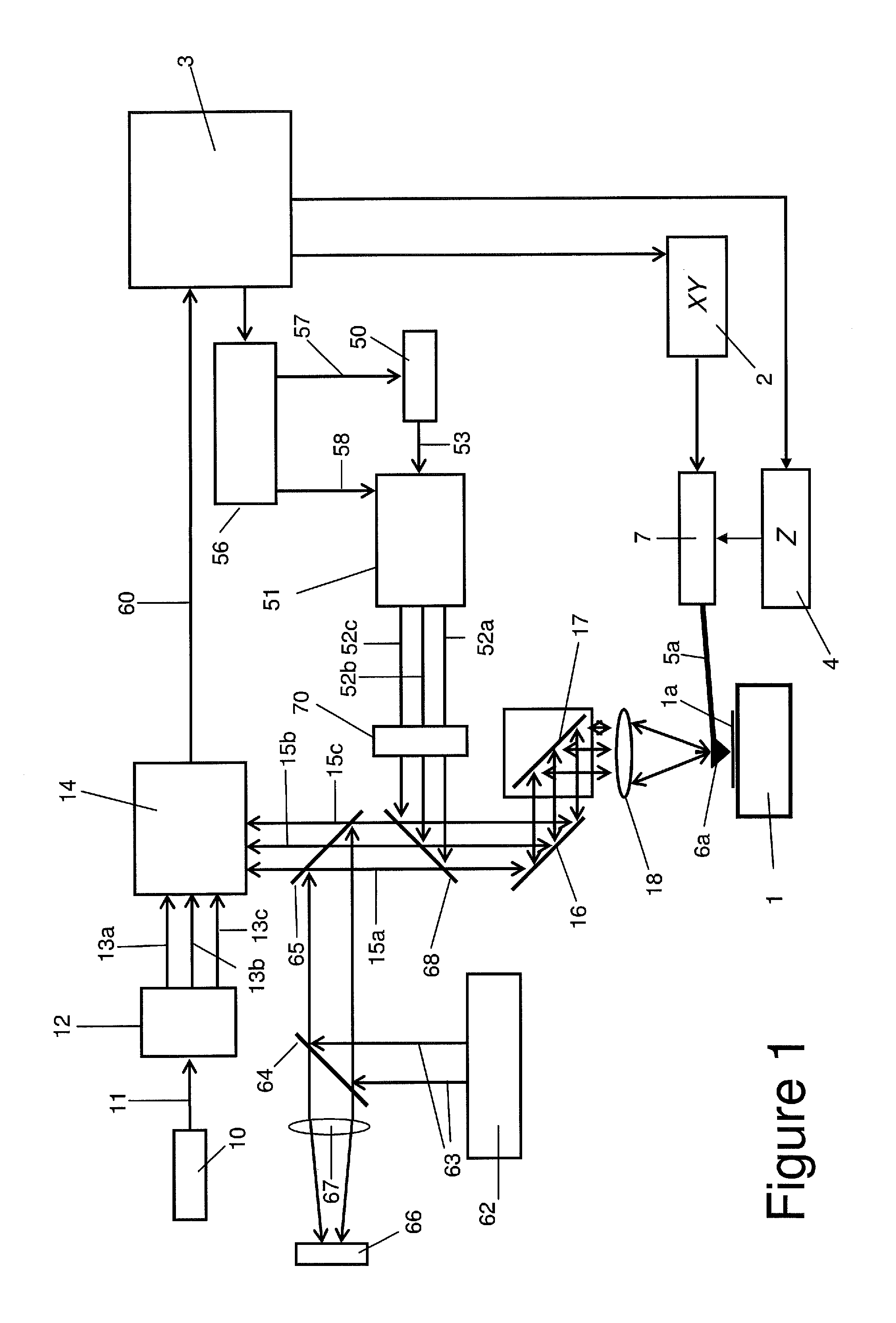

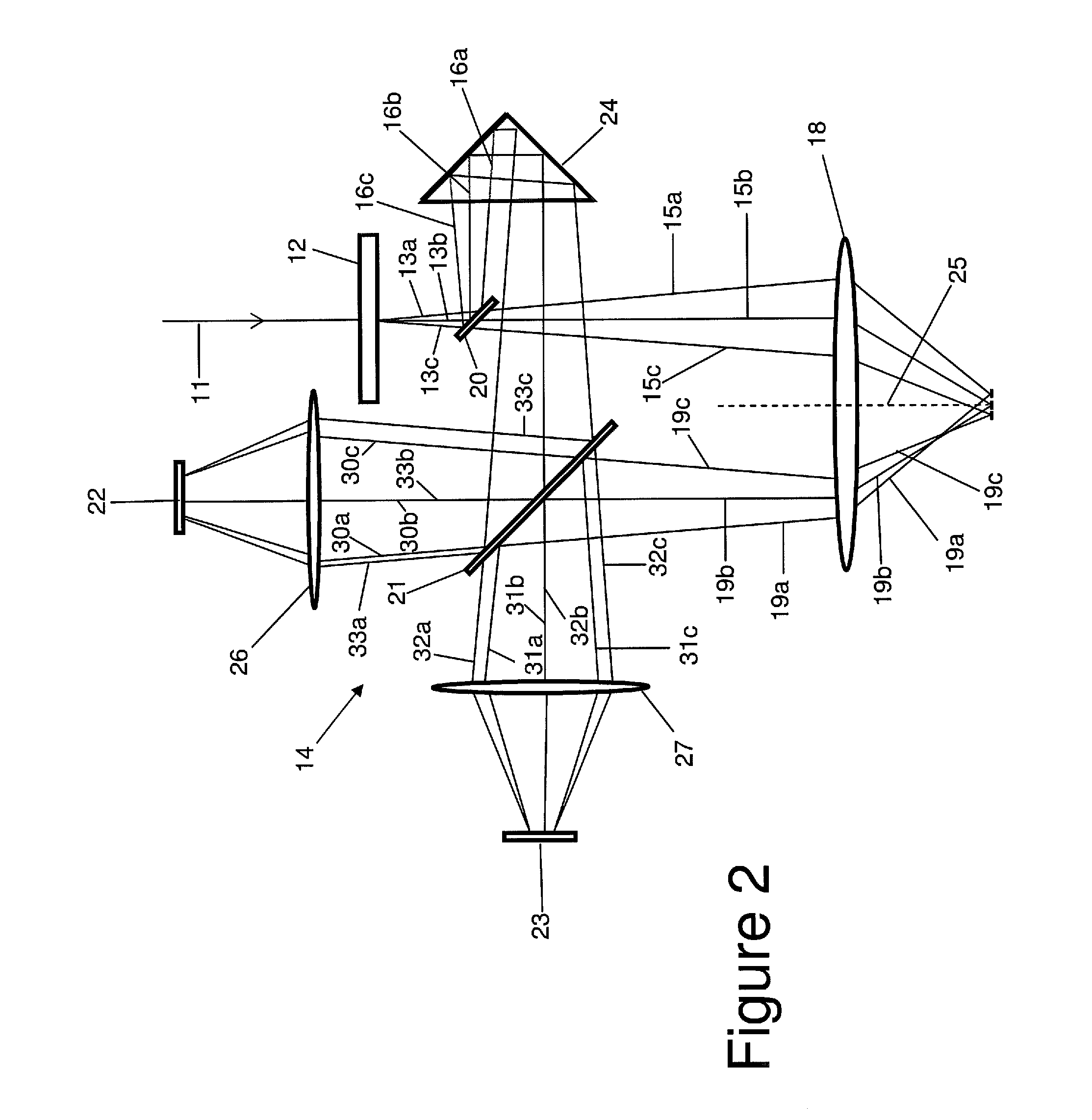

[0042]With reference to FIG. 1, a scanning probe microscope that incorporates an interferometer based sensing system and photothermal actuation system in accordance with the present invention is shown. The microscope comprises a moveable stage 1 adapted to receive a sample 1a whose surface is to be investigated by an array of thermal actuated bimorph probes, only one of which is shown in FIG. 1. The scanning capability is provided by two conventional drive systems: an x,y scanner 2 operable by an SPM controller 3 to provide relative motion of the probe array in the plane (x, y) of the sample 1a; and a z positioning system comprising piezoelectric drivers 4 operable to move the probe and sample towards and away from each other (z direction) over ranges larger than that achievable by the photothermal actuation of the probe array.

[0043]The probe array comprises a linear array of cantilever beams 5a, each carrying a tip 6a which tapers to a point, and which is located towards a distal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com