Apparatus and Method for Harvesting and Dewatering of Microalgae Biomass

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

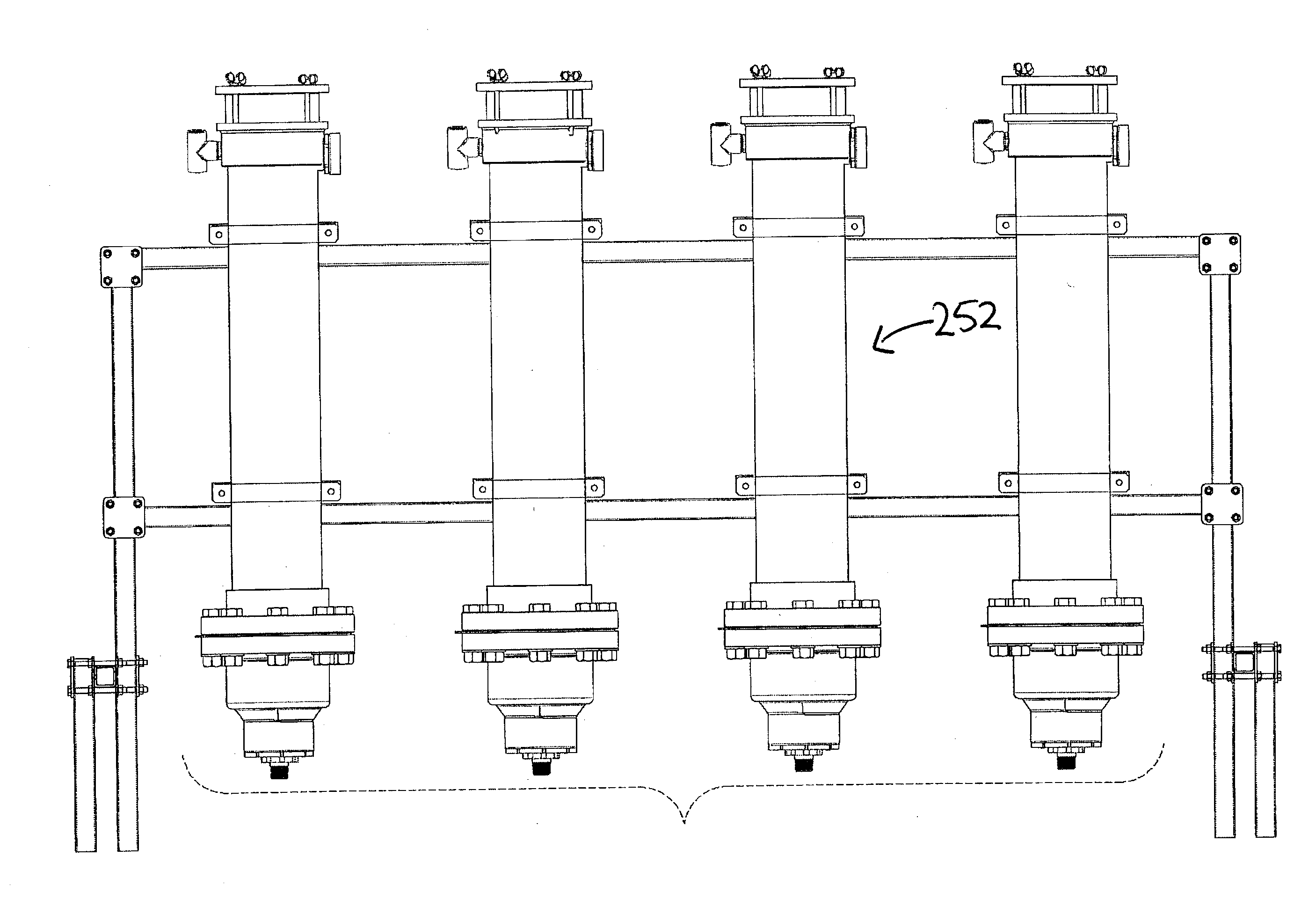

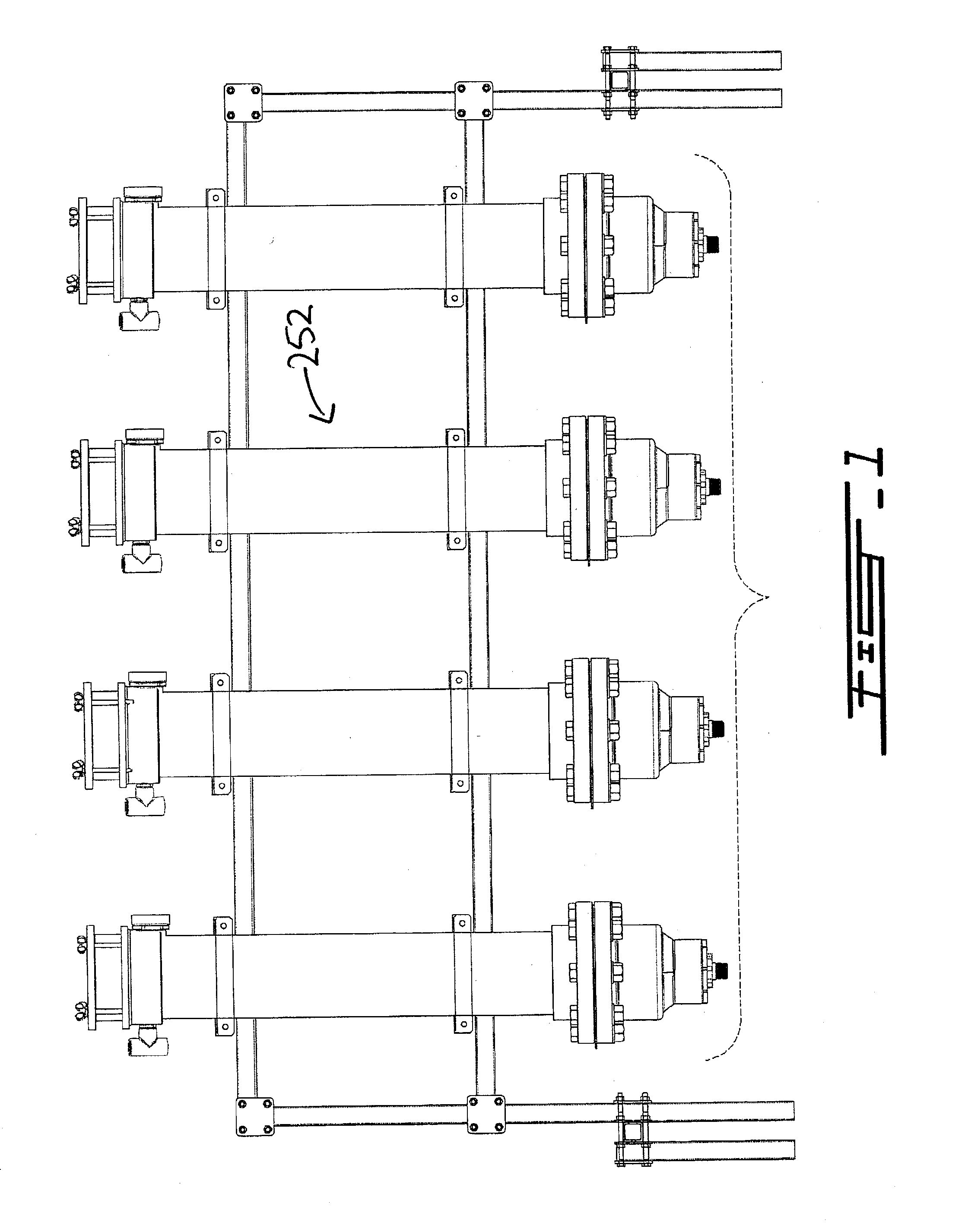

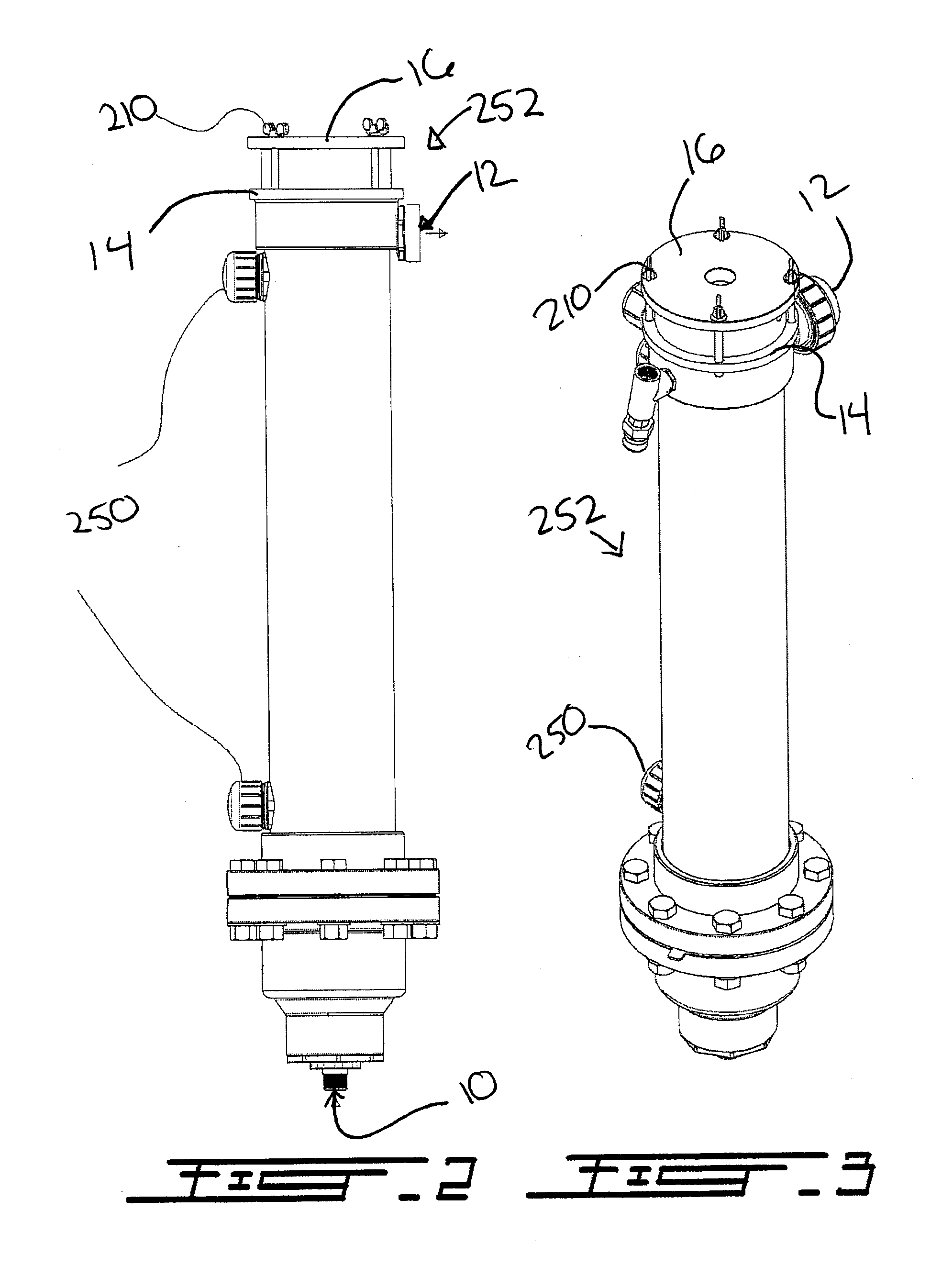

[0043]In the present embodiment, now referring to FIG. 1, a system comprising a plurality of electrocoagulation module is shown. In this embodiment, the plurality of reactors are arranged in a modular arrangement to make up an electrolysis skid. In this embodiment, four electrolysis reactors are arranged in a single skid that is connected to a single control panel, including a Programmable Logic Controller (PLC) and a Human Machine Interface (HMI). The number of reactors required for treatment of fluid, typically a microalgae solution, will be a function of the dosage that must be applied to the variety and concentration of microalgae to be harvested and dewatered. Moreover, the design may be optimized with respect to other process steps and with respect to the working conditions that are being used.

[0044]In another embodiment, a skid could potentially comprise 1, 2, 3, 4, 5, or even more reactors. Likewise, it is possible to have more than one skid depending on the extent of the tr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Flow rate | aaaaa | aaaaa |

| Polarity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com