Coating of Graphene

a graphene and coating technology, applied in the field of graphene, can solve the problems of limiting the use of monolayers, device characteristics that are not very predictable, and dna translocation of single-stranded and double-stranded dna is in fact much more difficul

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

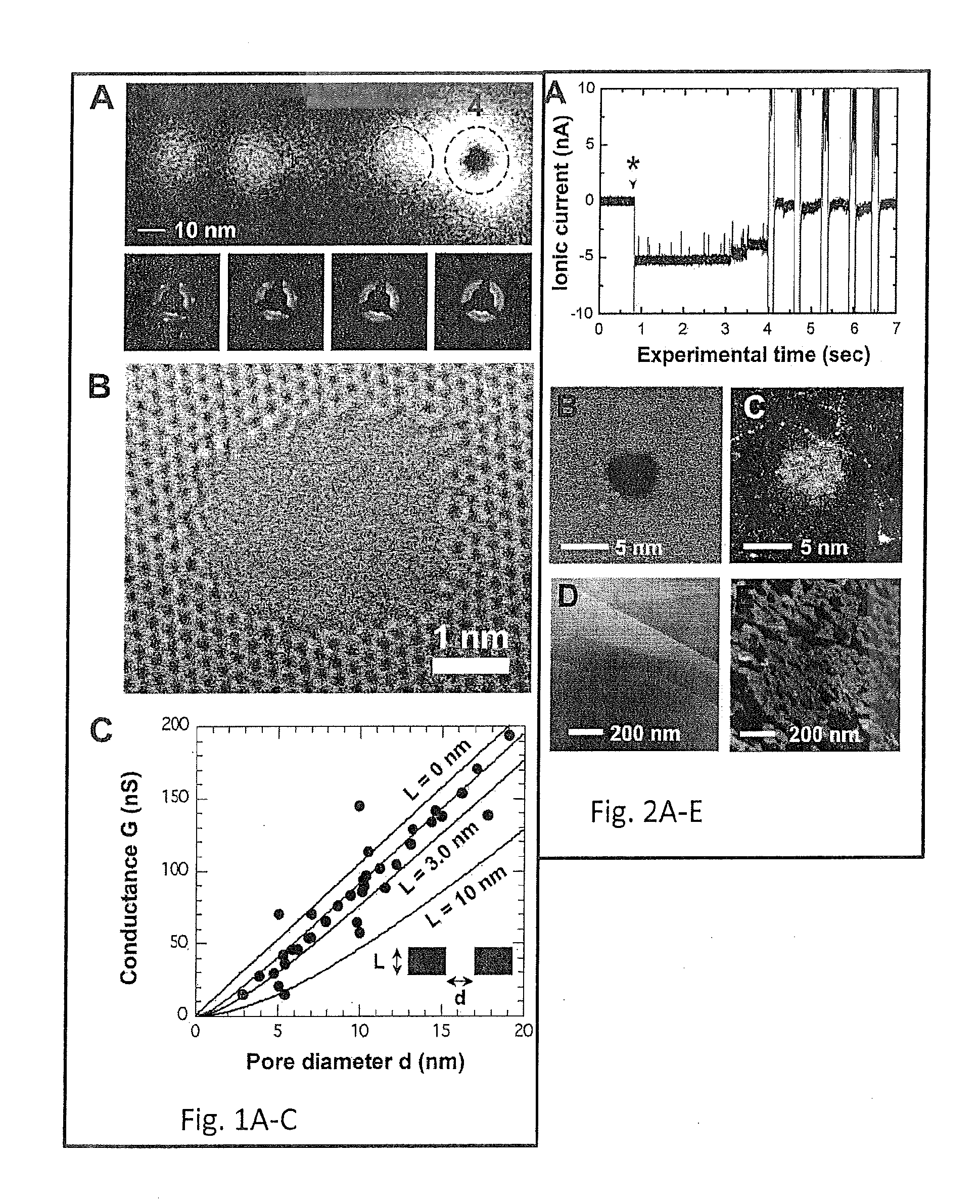

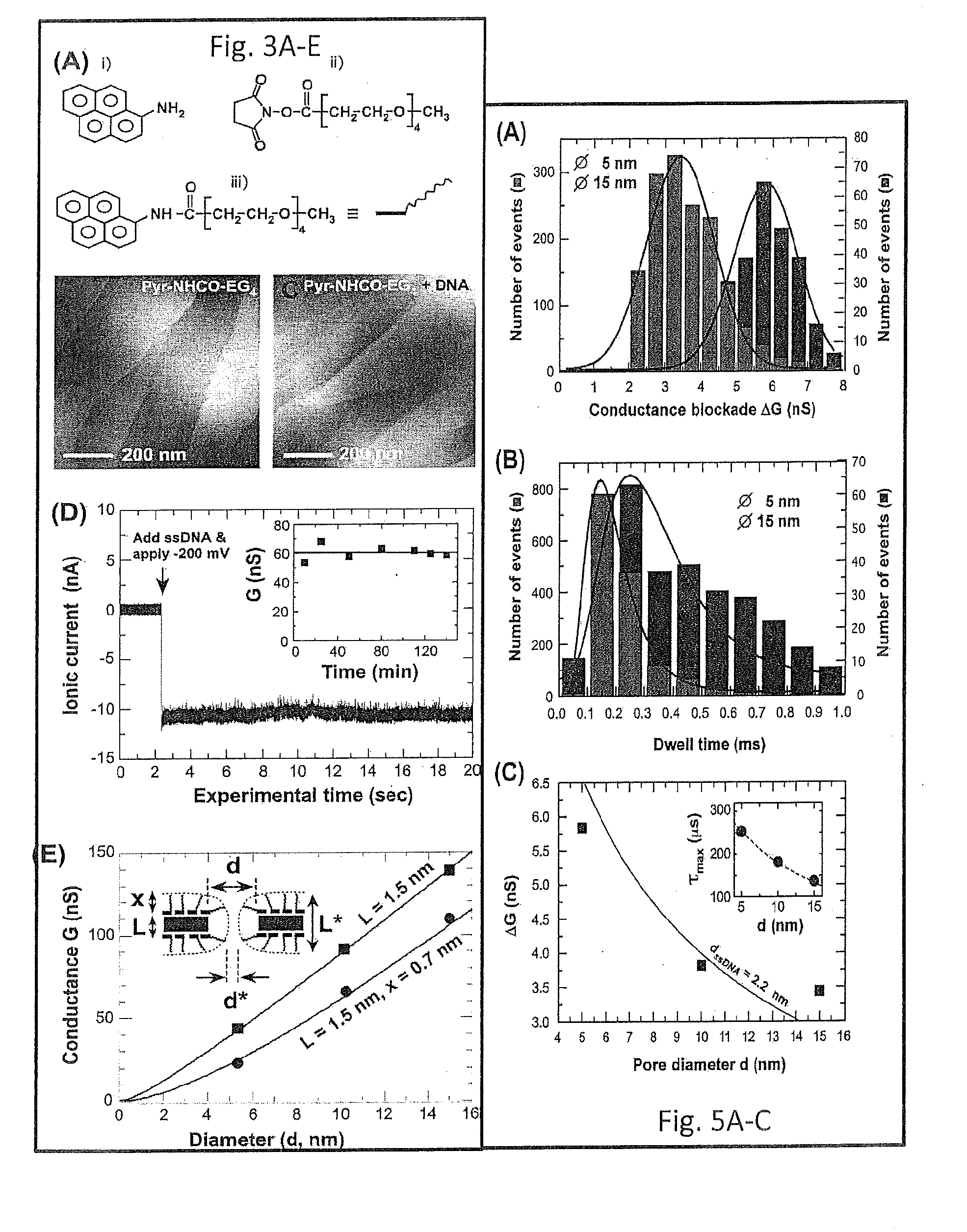

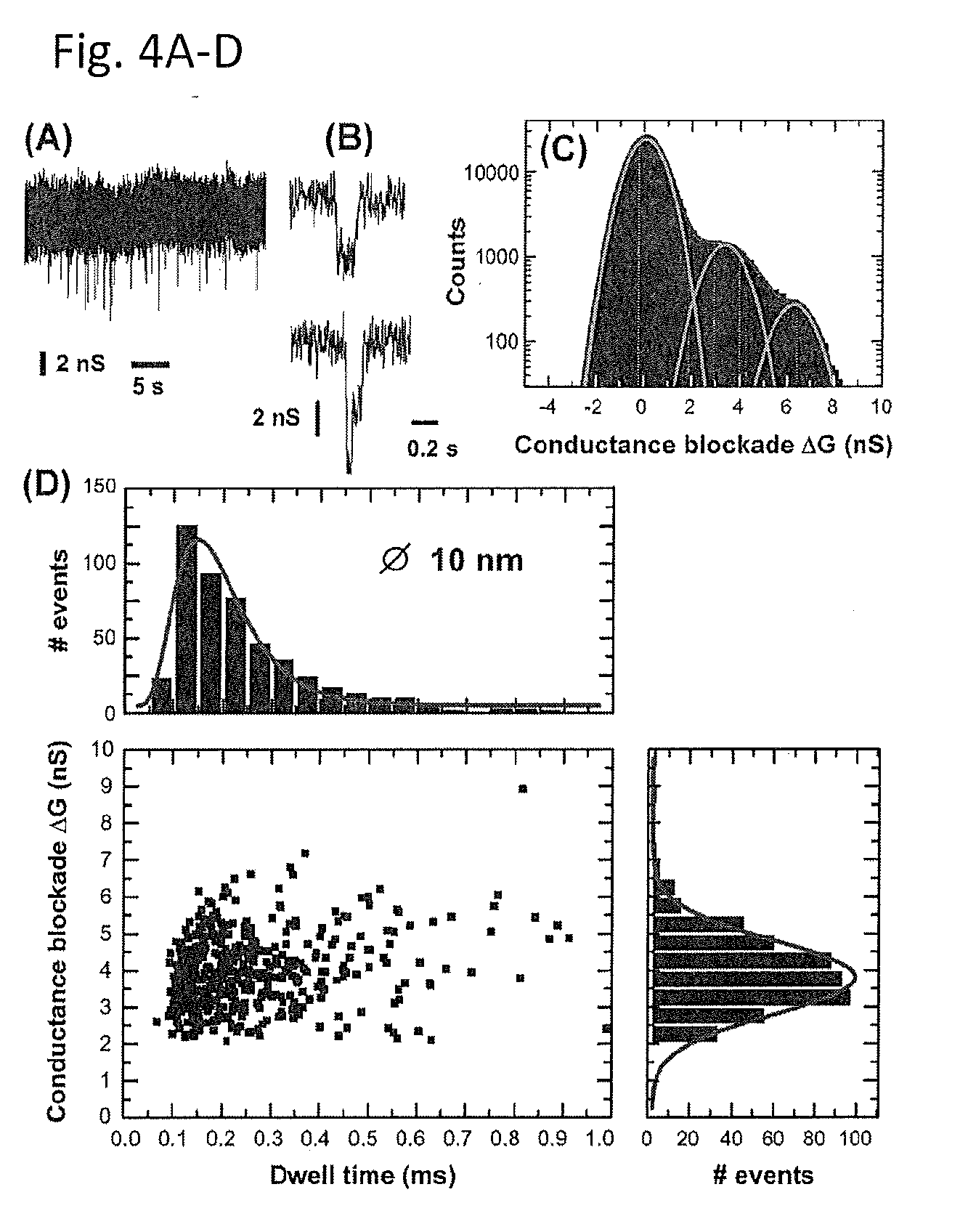

[0074]The invention although described in detailed explanatory context may be best understood in conjunction with the accompanying examples and figures.

TABLE S1Numerical solutionsDiameterG afterxxd (nm)coating (nS)(L = 0 nm)(L = 1.5 nm)5.122.10.90 ± 0.010.70 ± 0.0110.265.21.01 ± 0.010.76 ± 0.0114.91091.10 ± 0.020.82 ± 0.02

[0075]It should be appreciated that for commercial application it may be preferable to use one or more variations of the present system, which would similar be to the ones disclosed in the present application and are within the spirit of the invention.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| temperatures | aaaaa | aaaaa |

| diameters | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com