Breakable and degradalbe non-woven spunlace and fabrication methods and production line

a non-woven, degradable technology, applied in the direction of absorbent pads, non-woven fabrics, textiles and paper, etc., to achieve excellent formation strength, excellent breaking properties, and avoid second environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 1

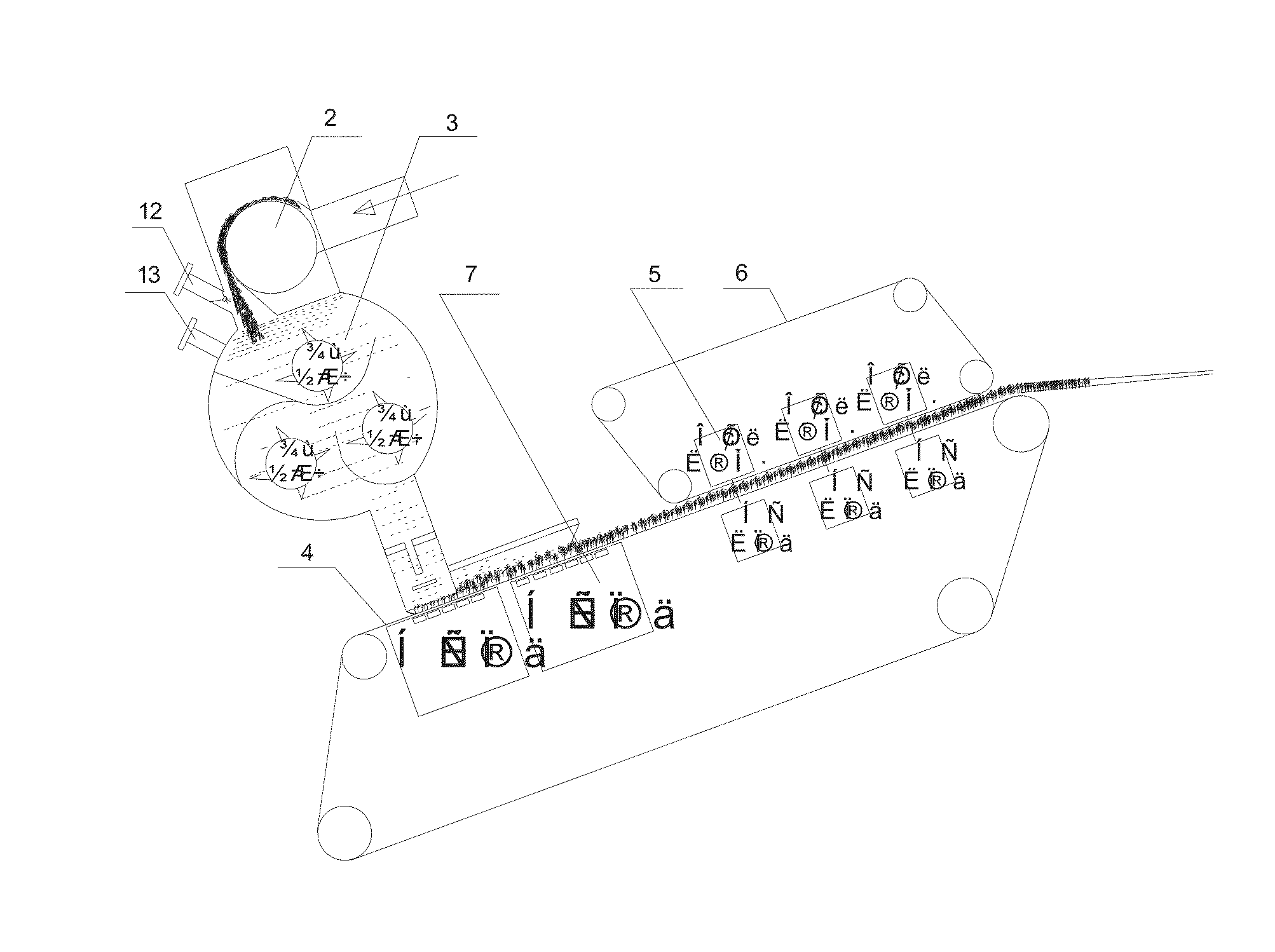

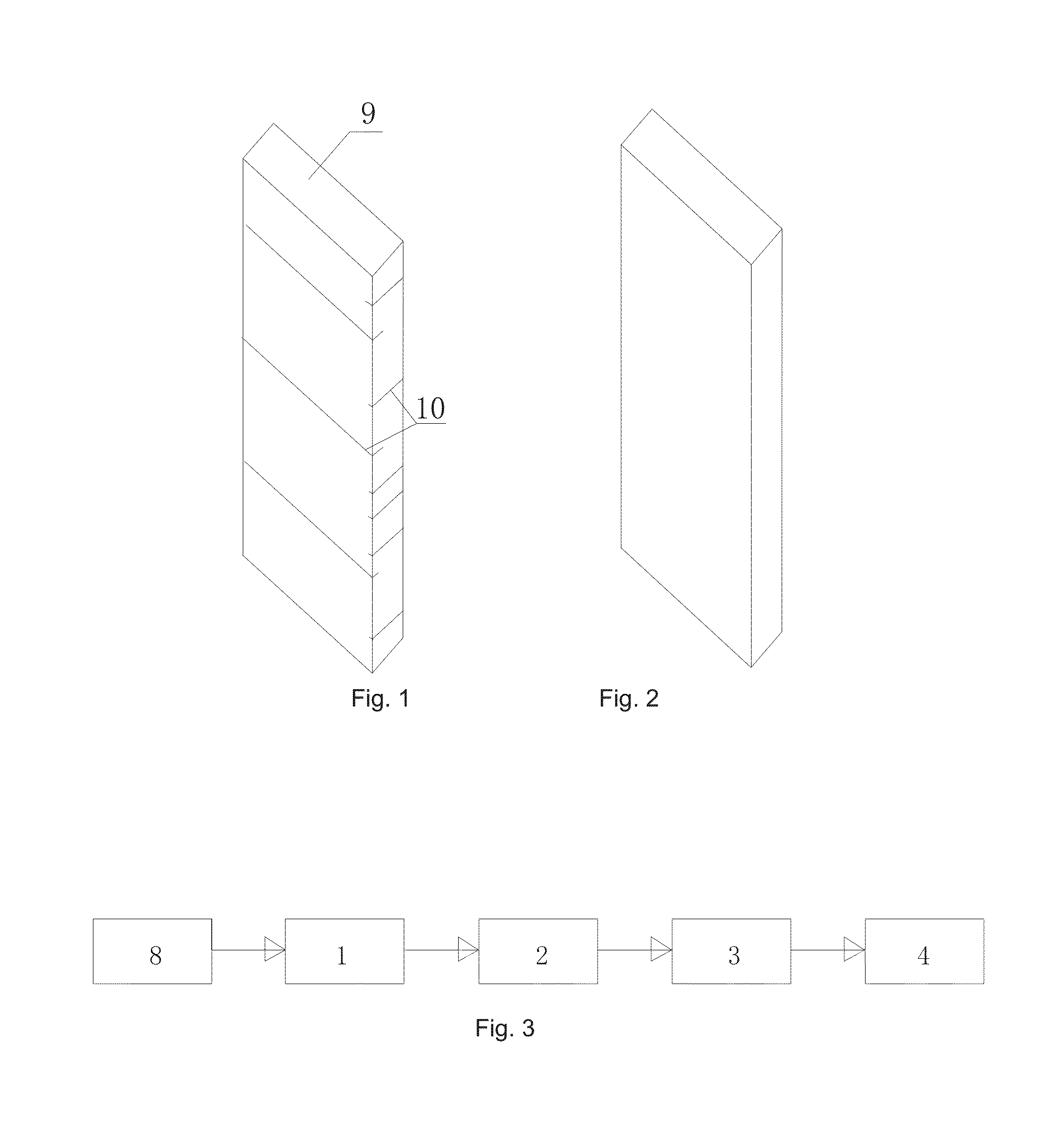

[0031] refer to FIGS. 1 and 2. It is a breakable and degradable non-woven spunlace composed of 35-50% zigzagging flat viscose fiber 9 and 65-50% wood pulp. The said zigzagging flat viscose fiber 9 means the deformed viscose fiber 10 upon cutting process. The said zigzagging flat viscose fiber (deformed viscose fiber 10) is 5-20 mm in length. >10 mm and ≦20 mm of the said 35-50% zigzagging flat viscose fiber (deformed viscose fiber 10) takes up 70-80%; ≧5 mm and ≦10 mm of the said 35-50% zigzagging flat viscose fiber (deformed viscose fiber 10) takes up 20-30%. The said wood pulp fiber is 1-5 mm in length. ≧1 mm and ≦3 mm of the said wood pulp fiber takes up 20-30%; >3 mm and ≦5 mm of the said wood pulp fiber takes up 80-70%. The technical index of breakable and degradable non-woven spunlace is as follows:

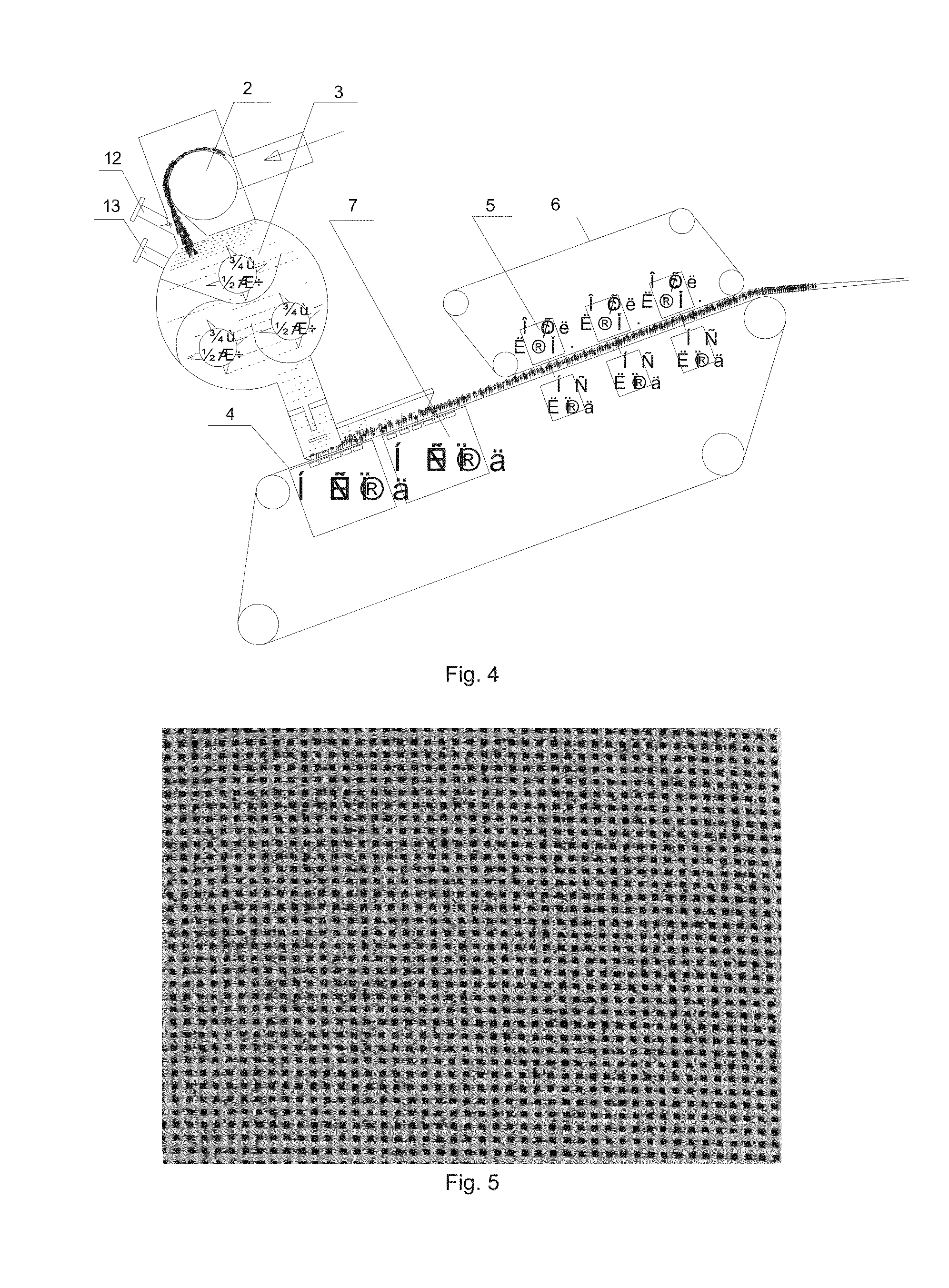

[0032]Water breakability—It receives sealed pipe swing test for 50 times and is thus broken into total fiber; gram weight: 30-100 gsm; humidity strength (MD): above 400 g / in.; CD: a...

embodiment 1-2

[0035] On the basis of embodiment 1, it is a breakable and degradable non-woven spunlace composed of 50% zigzagging flat viscose fiber 9 and 50% wood pulp. The said zigzagging flat viscose fiber 9 means the deformed viscose fiber 10 upon cutting process. >10 mm and ≦20 mm of the said 35-50% zigzagging flat deformed viscose fiber takes up 70-80%; ≧5 mm and ≧10 mm of the said 35-50% zigzagging flat viscose fiber takes up 20-30%. ≧1 mm and ≦3 mm of 65-50% wood pulp fiber takes up 30%; >3 mm and ≦5 mm of the said wood pulp fiber takes up 70%.

[0036]Embodiment 1-3: On the basis of embodiment 1, it is a breakable and degradable non-woven spunlace composed of 40% zigzagging flat viscose fiber 9 and 60% wood pulp. The said zigzagging flat viscose fiber 9 means the deformed viscose fiber 10 upon cutting process. >10 mm and ≦20 mm of the said 35-50% zigzagging flat deformed viscose takes up 70-80%; ≧5 mm and ≦10 mm of the said 35-50% zigzagging flat deformed viscose takes up 20-30%. ≧1 mm and ...

embodiment 2

[0037] it is a breakable and degradable non-woven spunlace composed of 35-50% zigzagging flat viscose fiber 9 and 65-50% wood pulp. The said zigzagging flat viscose fiber is 5-20 mm in length.

[0038]Embodiment 2-1: On the basis of embodiment 1, it is a breakable and degradable non-woven spunlace composed of 35% zigzagging flat viscose fiber 9 and 65% wood pulp. The said zigzagging flat viscose fiber is 20 mm in length.

[0039]Embodiment 2-2: It is a breakable and degradable non-woven spunlace composed of 50% zigzagging flat viscose fiber 9 and 50% wood pulp. The said zigzagging flat viscose fiber is 5 mm in length.

[0040]Embodiment 2-3: It is a breakable and degradable non-woven spunlace composed of 40% zigzagging flat viscose fiber 9 and 60% wood pulp. The said zigzagging flat viscose fiber is 10 mm in length.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com