Binder coated refractories, casting mold using the same, and method of manufacturing casting mold using the same

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

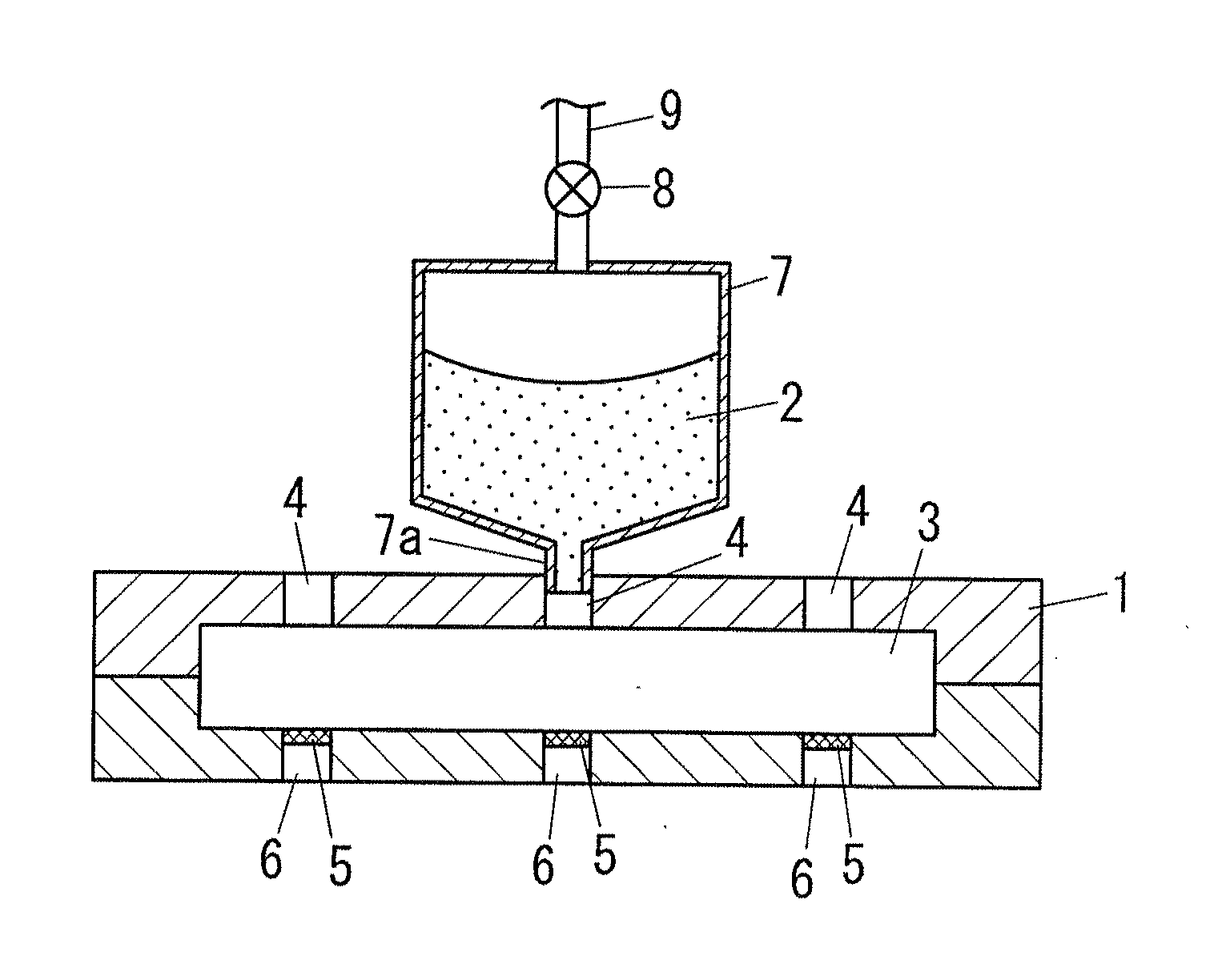

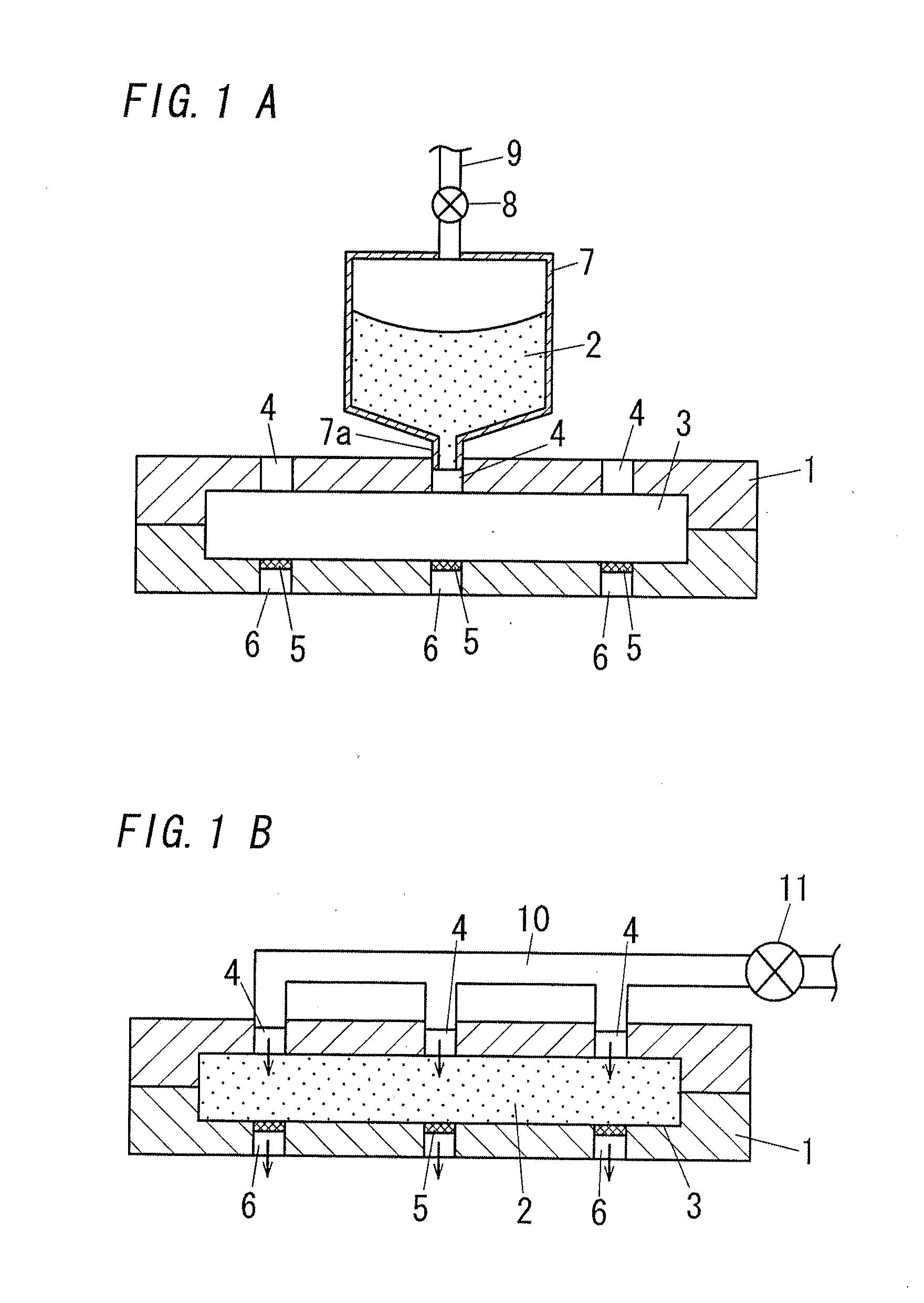

Image

Examples

example

[0086]Next, the example is specifically explained in the followings.

examples 1 to 9

[0087]The 30 kilograms flattery silica sand heated to 130 degrees C. was supplied to the whirlmixer. Then, the water solution of “the sugar group and the curing agent indicated in the Table 1” dissolved to or dispersed in the water of 450 grams was supplied to the whirlmixer. Then, the mixture is kneaded for 90 seconds. After breaking the mixture, the calcium stearate as the lubricant was added to the mixture. Then, the aeration was made to the mixture. In this manner, the binder coated refractories having the coating layer made of the sugar group was obtained. The binder coated refractories has the coating layer having the weight ratio of 2 percents by mass.

[0088]In addition, as shown in Table 1, the sugar group of the following was used.[0089]Dextrin (“No4-C”“No. 102-S”“ND-S” of NIPPON STARCH CHEMICAL Col. Ltd.)[0090]Enzyme Denaturation Dextrin (“Amycol No7-H”“Amycol No6-H”“amycol No3-L” of NIPPON STARCH CHEMICAL Col. Ltd.)[0091]White Superior Soft Sugar (Sucrose 98 percents by ma...

examples 10 to 13

[0092]The 30 kilograms flattery silica sand heated to 140 degrees C. was supplied to the whirlmixer. Then, the phenol resin indicated in Table 2 was added to the whirlmixer and then mixed with flattery silica sand. Then, the water solution of “the sugar group in Table 2” was dissolved to or dispersed in the water of 450 grams was added to the mixture of the flattery silica sand and the phenol resin. Then, kneading the mixture for 90 seconds was performed. Subsequently, the aeration was made, whereby the binder coated refractories having the coating layer including the sugar group and the phenol resin was produced. The binder coated refractories had the coating layer having the weight ratio of 2.0 percents by mass.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com