Method and Apparatus for Extracting Plant Oils Using Ethanol Water

a technology of plant oils and ethanol water, which is applied in the direction of azeotropic distillation, vacuum distillation separation, separation process, etc., can solve the problems of slow, cbns is less practical, and smoking as a method of drug administration suffers from the inherent dangers of smoking, so as to eliminate any flammability hazards, less ballast contamination, and plant oil is more intact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

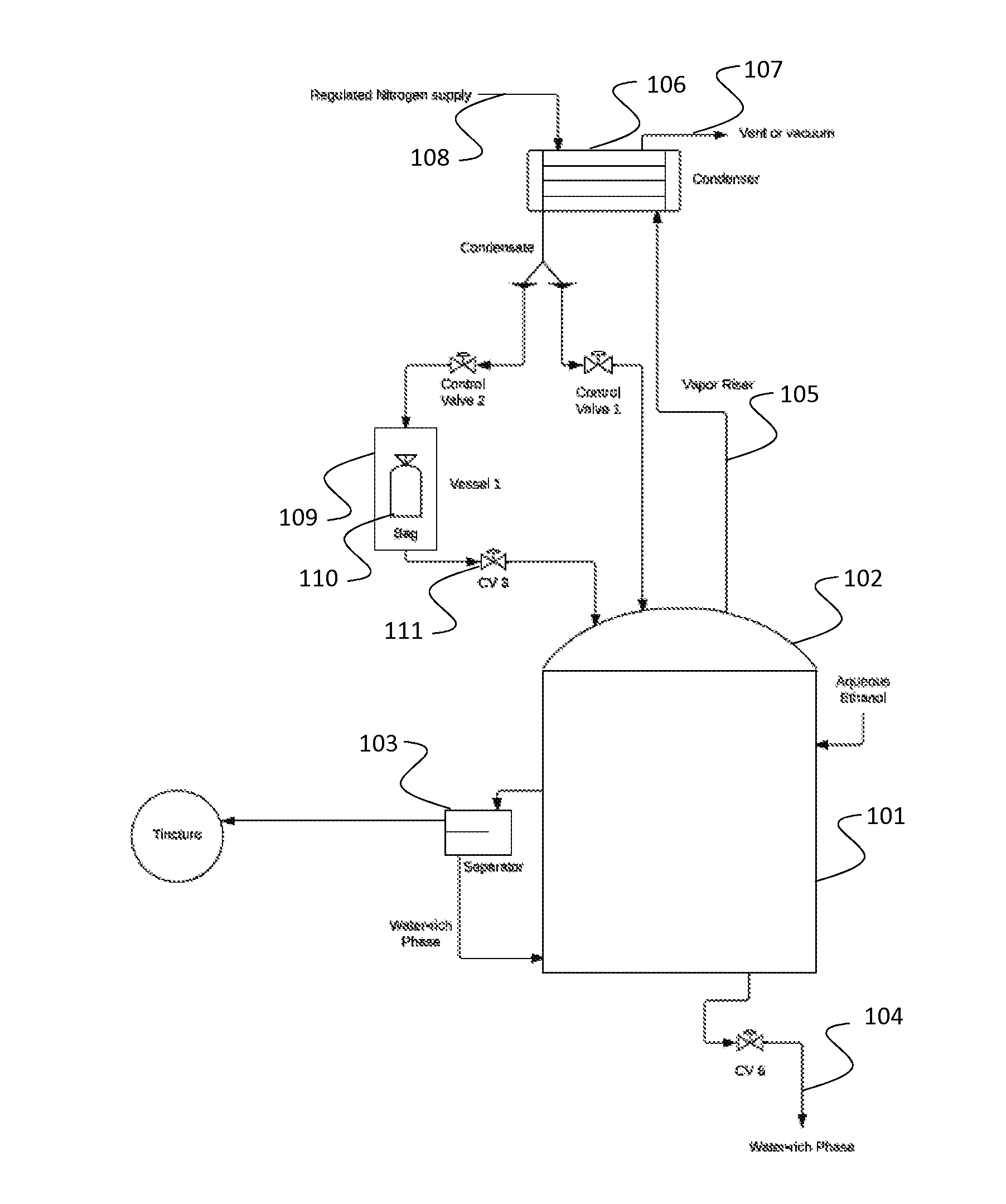

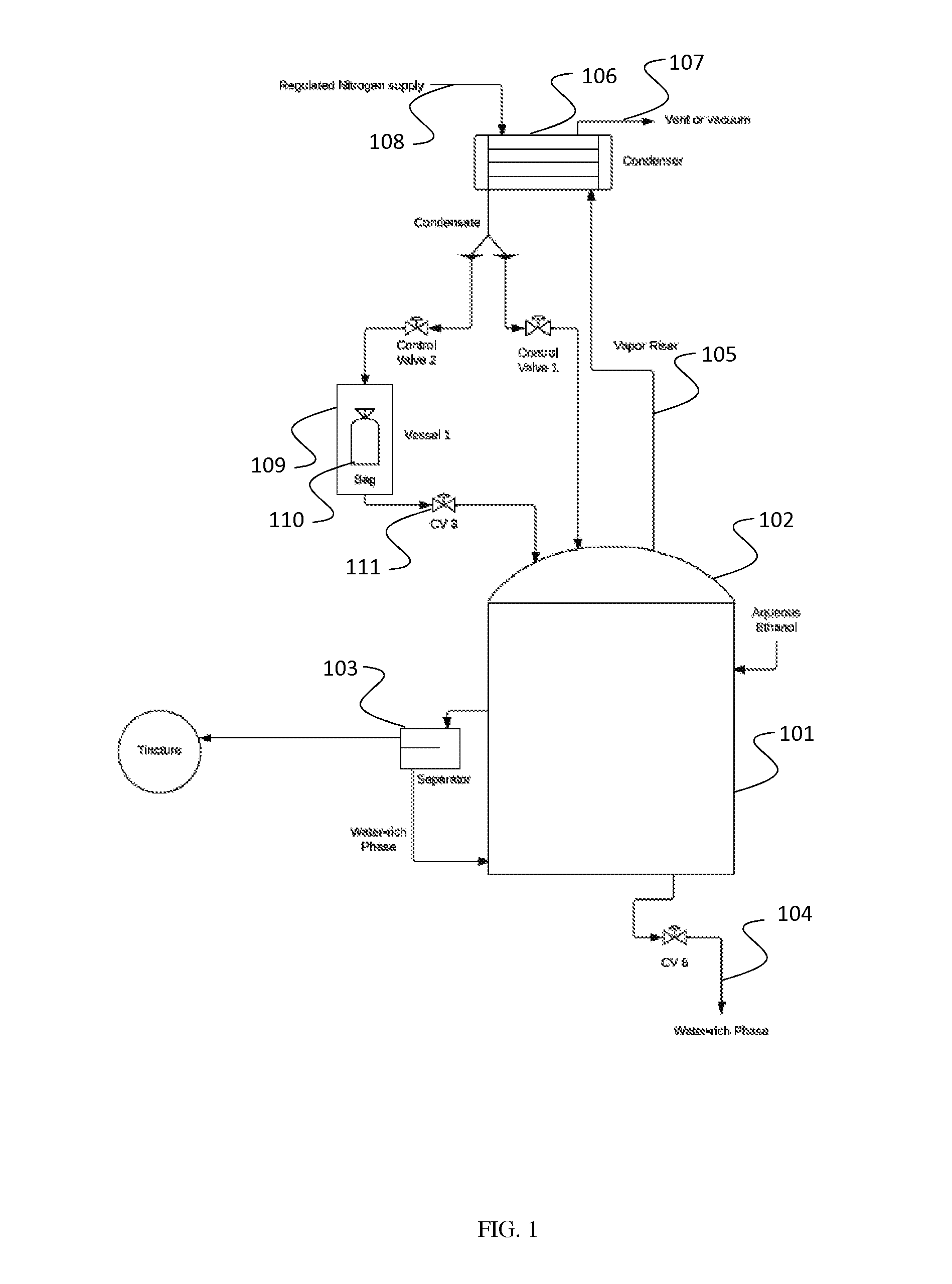

[0074]the invention is a semi-continuous Extraction System 100, detailed in FIG. 1 where the system is fabricated from stainless steel, glass or any other suitable material and is composed of a 20 L boiling pot 101 that in other embodiments may be larger or smaller in volume. The boiling pot 101 is disposed with a vented lid 102. In this embodiment the vented lid 102 is also disposed with ports (not shown) for return flow. In this embodiment the boiling pot 101 is also disposed with side-ports (not shown) for attachment of a separator 103 and with a drain 104. The boiling pot 101 may be filled with ethanol and water at any ratio below 95:5. Applying heat to boiling pot 101 produces a 95% ethanol / water azeotrope that escapes from the vented lid 102 and enters the input end of a distillation column 105. The 95% ethanol azeotrope is constant and absolute as long as the boiling pot 101 has enough ethanol. In some embodiments an intermediate region of the distillation column 105 may cont...

second embodiment

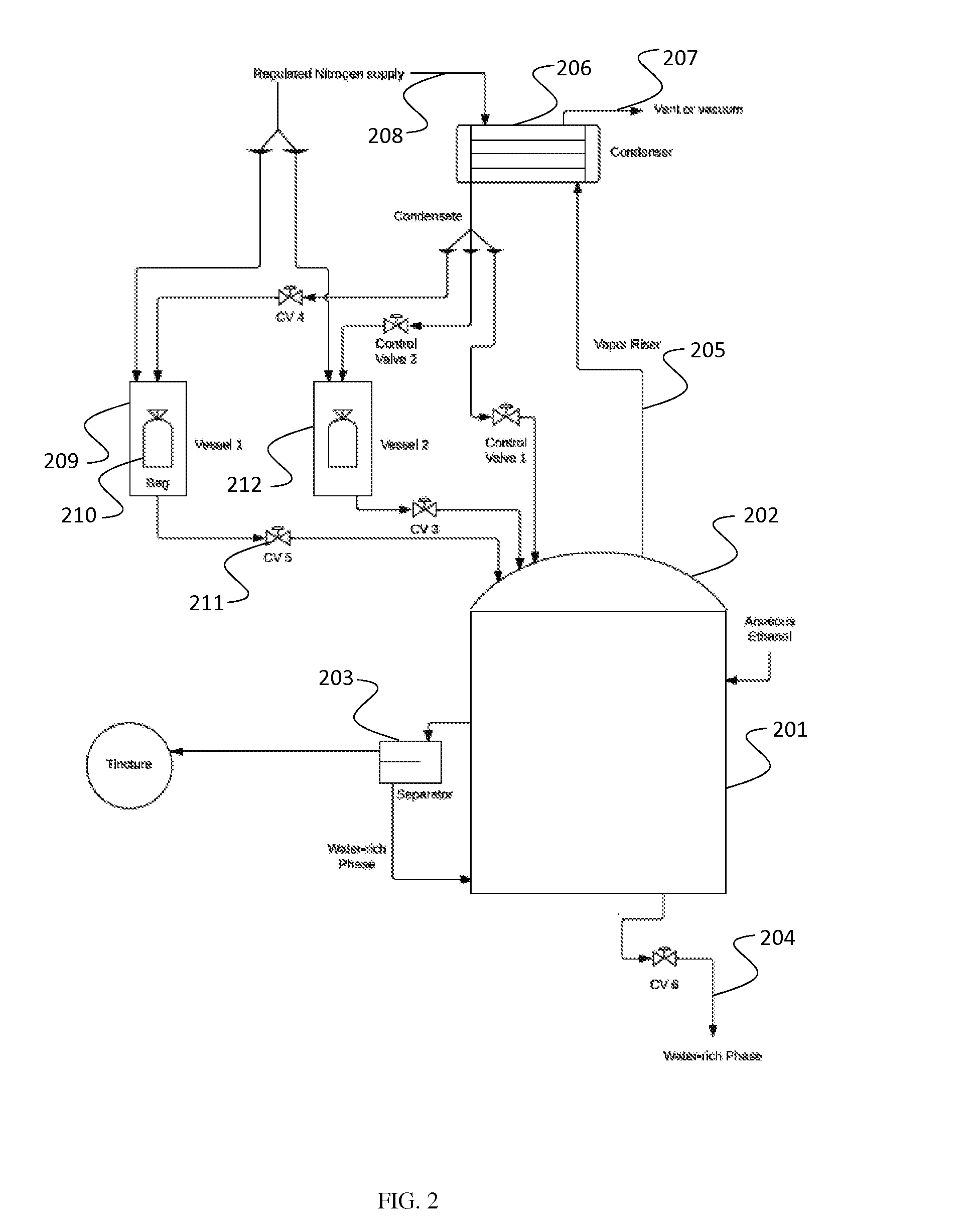

[0077]A second embodiment is a continuous Extraction System 200, (FIG. 2). A continuous process entails using at least two and in some embodiments a multiplicity of vessels 209 containing oil bearing plant tissue. When the plant tissue in vessel 209 is exhausted, the necessary control valves 211 are opened and closed so that condensate passes through vessel 212 containing fresh plant material. Vessel 209 can be emptied of spent plant tissue and then replenished with fresh plant material while the train is set to extract from vessel 212. In one embodiment spent plant material can be used for other purposes and will be stored for resale. As long as fresh plant matter is supplied to the system, ethanol and / or water are replenished to maintain the desired composition in the boiling pot 201, chloroplasts and other cellular debris are removed from the bottom of boiling pot 201, the process can be run indefinitely. In a further embodiment, added food oil, such as but not limited to vegetab...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com