Systems and methods for producing a sugar stream

a technology of dry grinding and sugar stream, which is applied in the direction of glucose production, waste based fuel, biomass after-treatment, etc., can solve the problems of complex and costly wet grinding process, high capital investment, and high operating costs, and achieve the effect of clean sugar stream and increased revenu

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

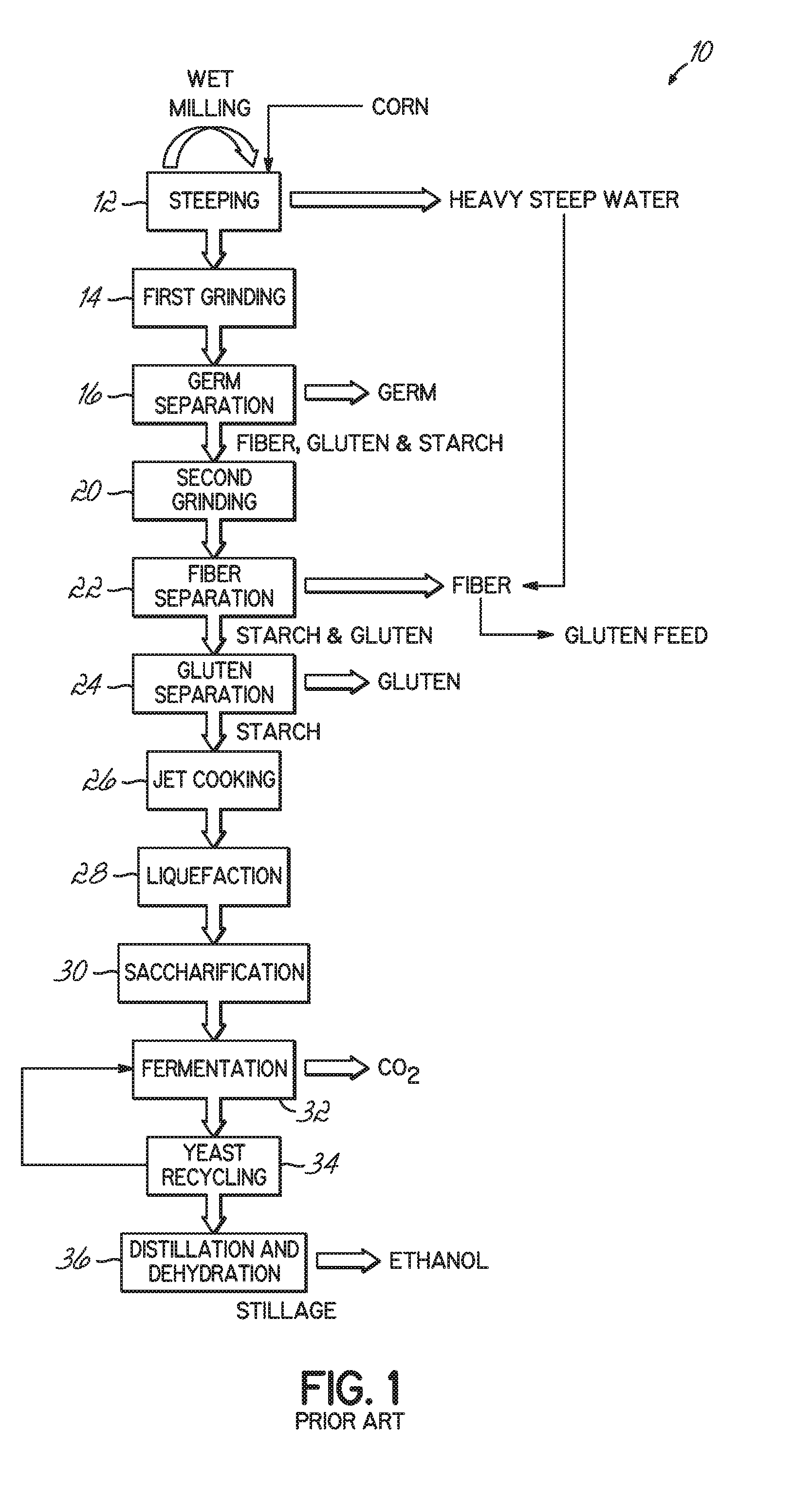

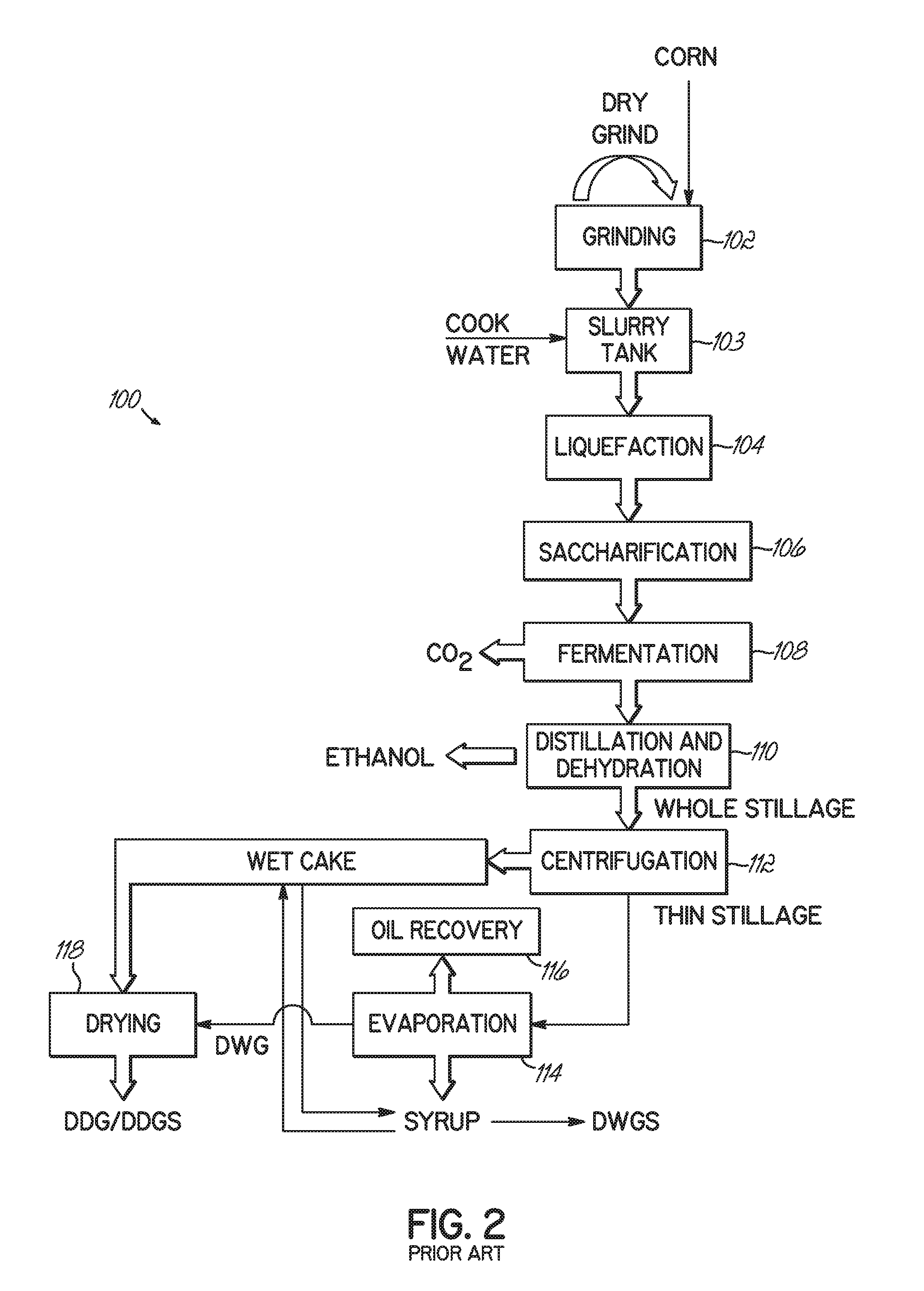

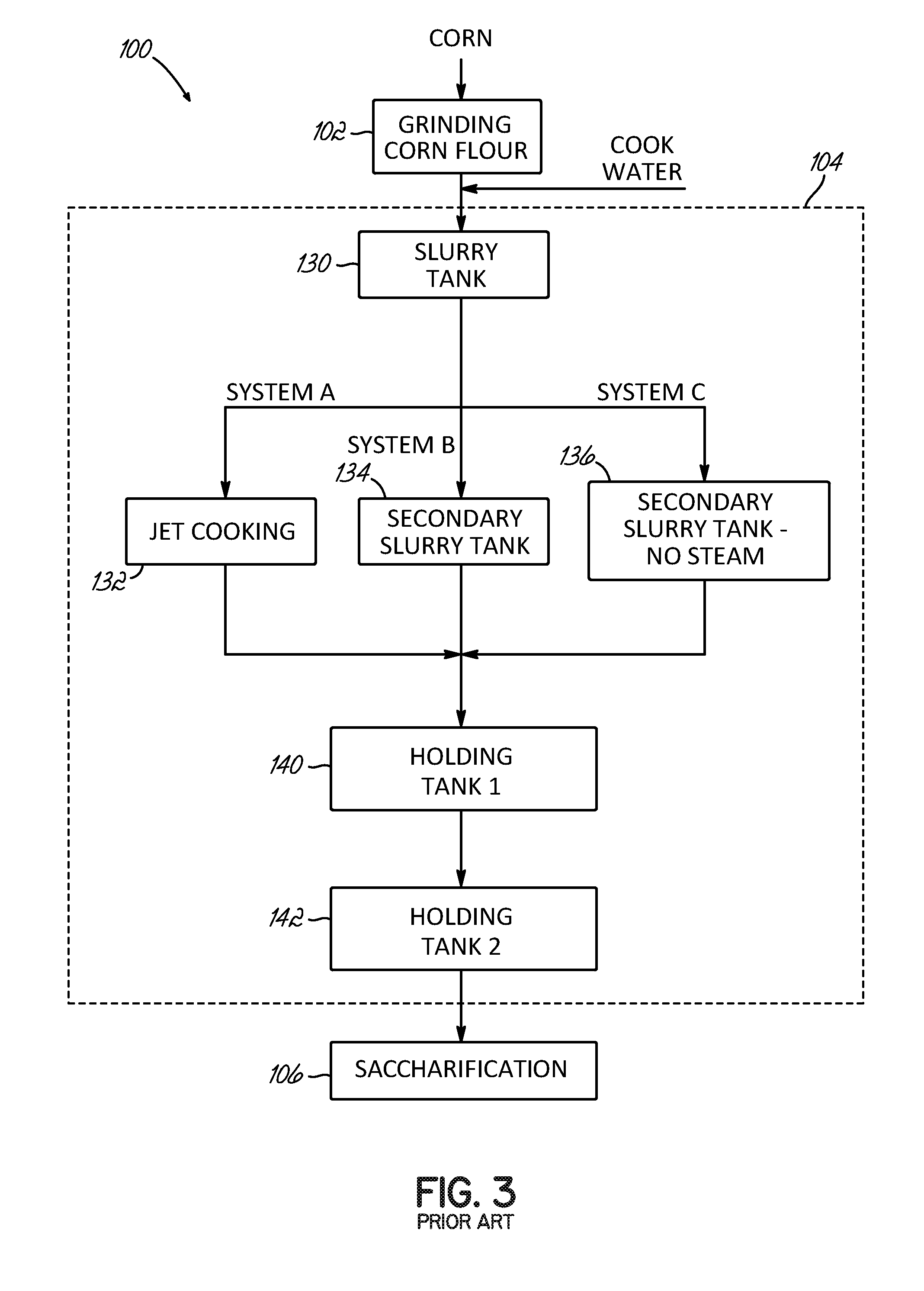

[0032]FIGS. 1 and 2 have been discussed above and represent flow diagrams of a typical wet mill and dry grind alcohol production process, respectively. FIG. 3, likewise, has been discussed above and represents various typical liquefaction processes in a typical dry grind alcohol production process.

[0033]FIGS. 4-6 illustrate embodiments of a dry grind system and method 200, 300, 300a for producing a sugar stream from grains or similar carbohydrate sources and / or residues, such as for biofuel production, in accordance with the present invention. As further discussed in detail below, a sugar / carbohydrate stream, which includes a desired Dextrose Equivalent (DE) where DE describes the degree of conversion of starch to dextrose (aka glucose) and / or has had removed therefrom an undesirable amount of unfermentable components, can be produced after saccharification and prior to fermentation (or other sugar conversion process), with such sugar stream being available for biofuel production, e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com