Manufacturing method and apparatus for manufacturing silicon carbide epitaxial wafer

a manufacturing method and epitaxial wafer technology, applied in the direction of crystal growth process, cleaning of hollow articles, chemically reactive gases, etc., can solve the problems of easy formation of silicon carbide particles, generating leak current, and structural brittleness of attached silicon carbide, so as to reduce crystal defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

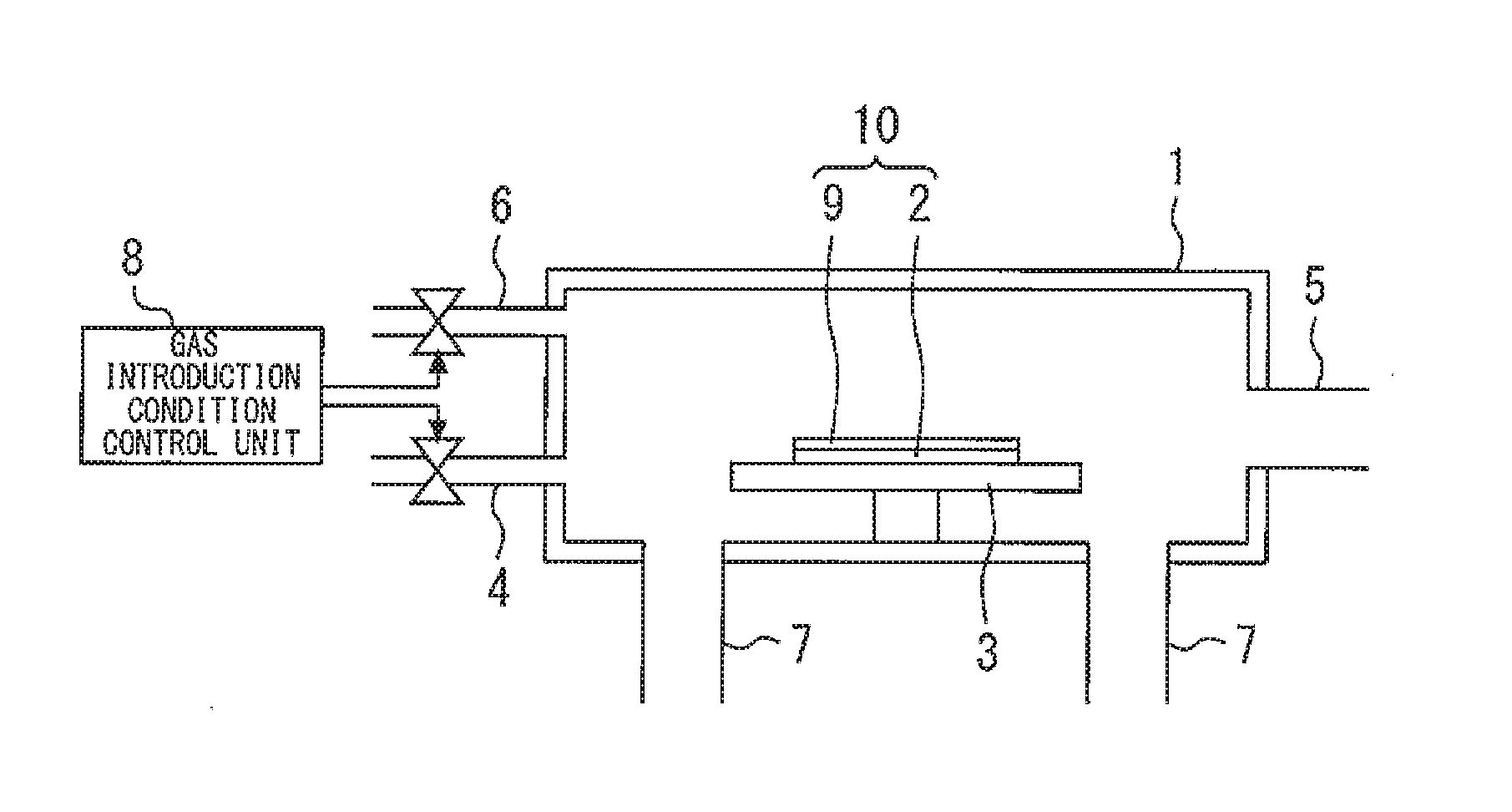

[0019]FIG. 1 is a sectional view of an apparatus for manufacturing a silicon carbide epitaxial wafer according to a first embodiment of the present invention. A wafer holder 3 on which a silicon carbide substrate 2 is mounted is provided in a growth furnace 1 (epitaxial growth furnace) in which epitaxial growth is performed. A processing gas introduction port 4 introduces a processing gas including a carrier gas and a raw-material gas into the growth furnace 1 in an epitaxial growth step. A processing gas exhaust port 5 discharges from the growth furnace 1 the processing gas introduced through the processing gas introduction port 4.

[0020]A cleaning gas introduction port 6 introduces, into the growth furnace 1, in a cleaning step, a cleaning gas for removing silicon carbide in polycrystalline form of dendrite-like structure attached to inner wall surfaces of the growth furnace 1. Gas exhaust ports 7 discharge from the growth furnace 1 the cleaning gas introduced through the cleaning ...

second embodiment

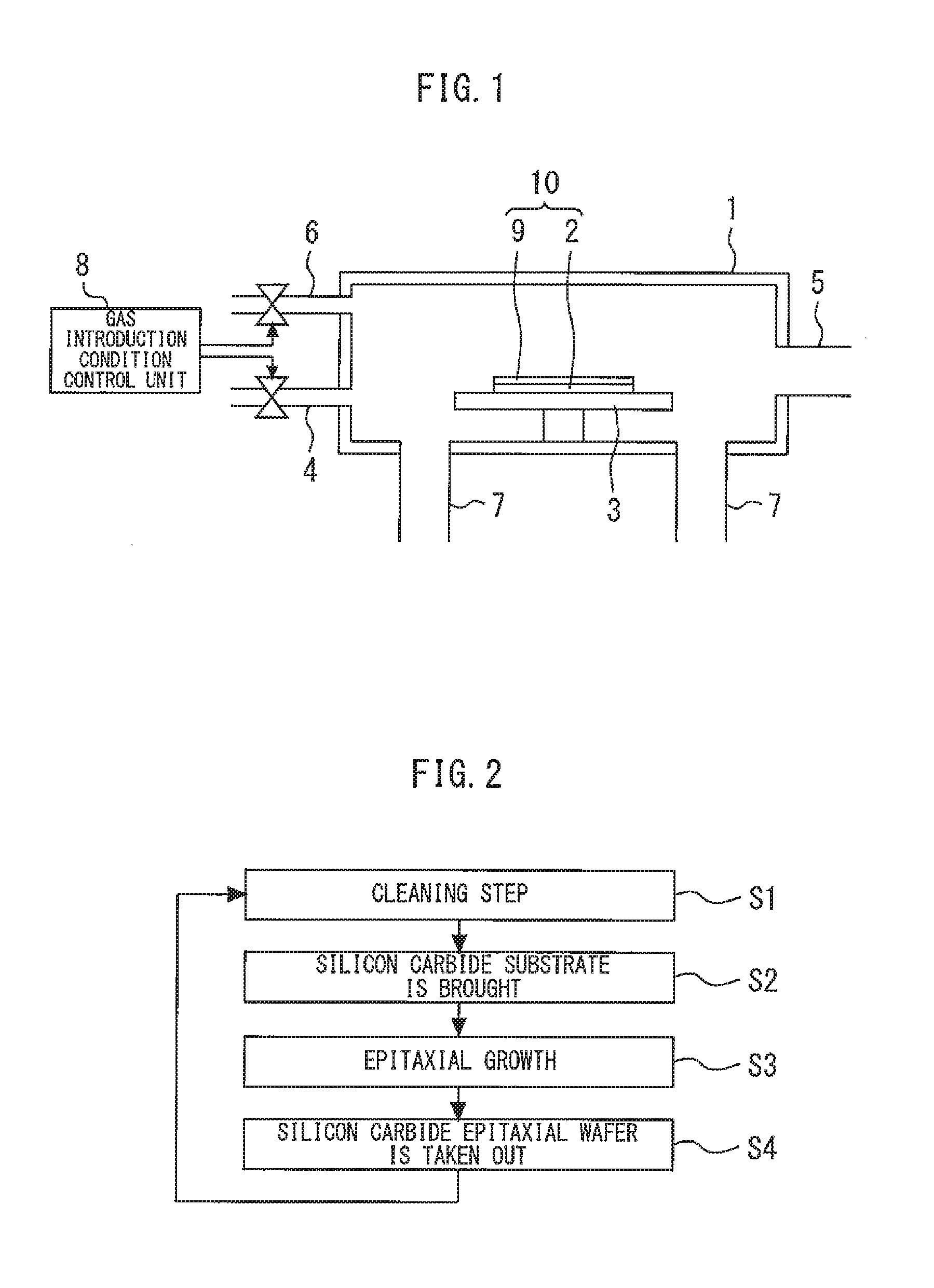

[0031]FIG. 4 is a flowchart showing a silicon carbide epitaxial wafer manufacturing process according to a second embodiment of the present invention. The same manufacturing apparatus as that in the first embodiment is used for the manufacturing process in the second embodiment.

[0032]First, a cleaning step (step S1), a silicon carbide substrate 2 transport step (step S2) and an epitaxial growth step (step S3) are carried out, as those in the first embodiment, thereby forming the silicon carbide epitaxial wafer 10. These steps are the same as those in the first embodiment and detailed descriptions of them will not be repeated. After silicon carbide in polycrystalline form of dendrite-like structure attached to the inner wall surfaces of the growth furnace 1 and the wafer holder 3 is removed in the cleaning step (step S1), the epitaxial growth step (step S3) is executed. Therefore, substantially no silicon carbide particles are generated in the epitaxial growth step. The silicon carbi...

PUM

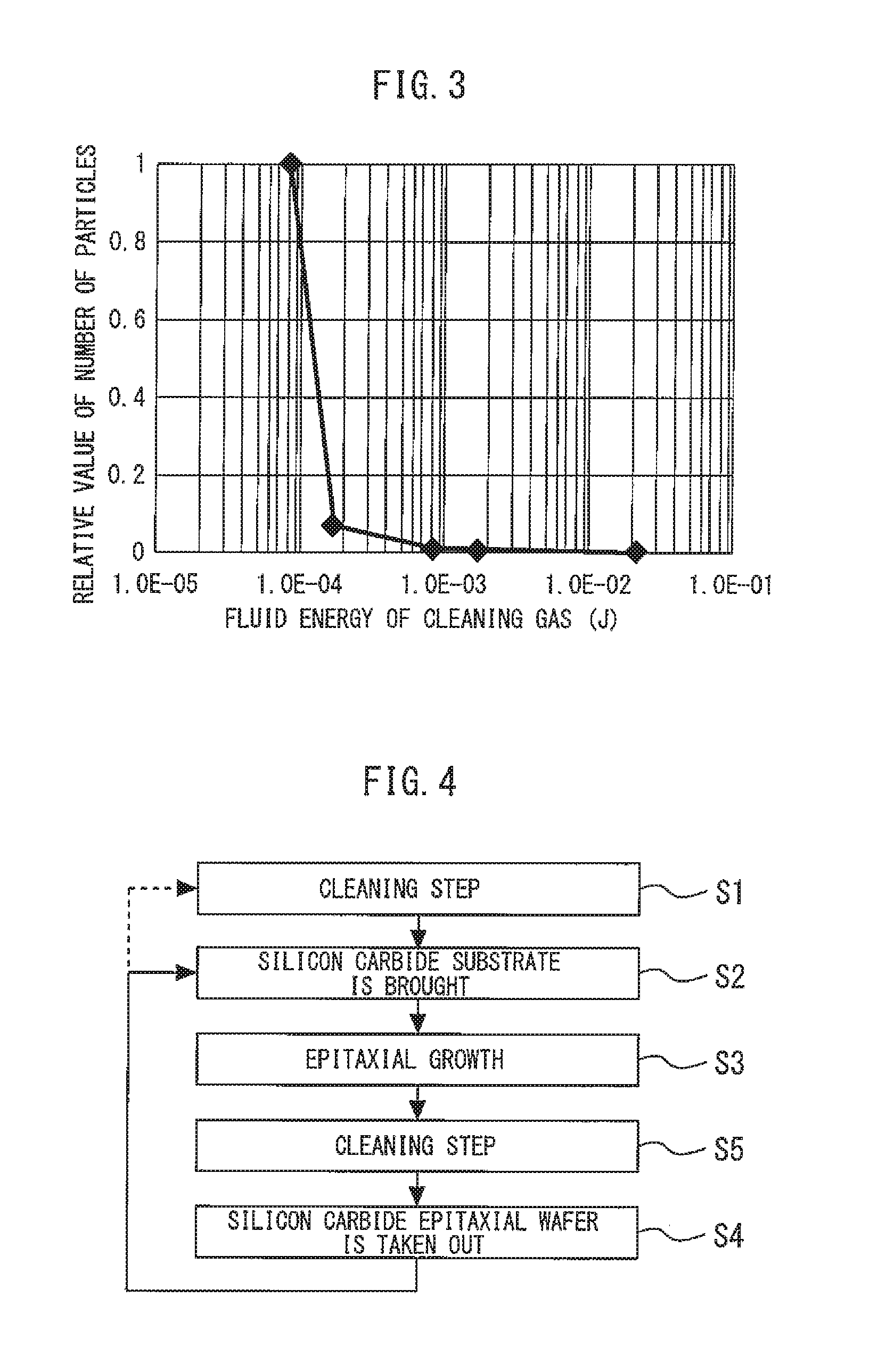

| Property | Measurement | Unit |

|---|---|---|

| fluid energy | aaaaa | aaaaa |

| fluid energy | aaaaa | aaaaa |

| fluid energy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com