Electronic module with free-formed self-supported vertical interconnects

a technology of self-supporting and electrical interconnection, which is applied in the direction of cooling/ventilation/heating modification, basic electric elements, semiconductor devices, etc., can solve the problems of affecting the operation of rf, generating a significant amount of heat, etc., and achieves improved thermal performance and cooling, improved compactness of electronic modules, and effective increase of the available area for mounting such electronic components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

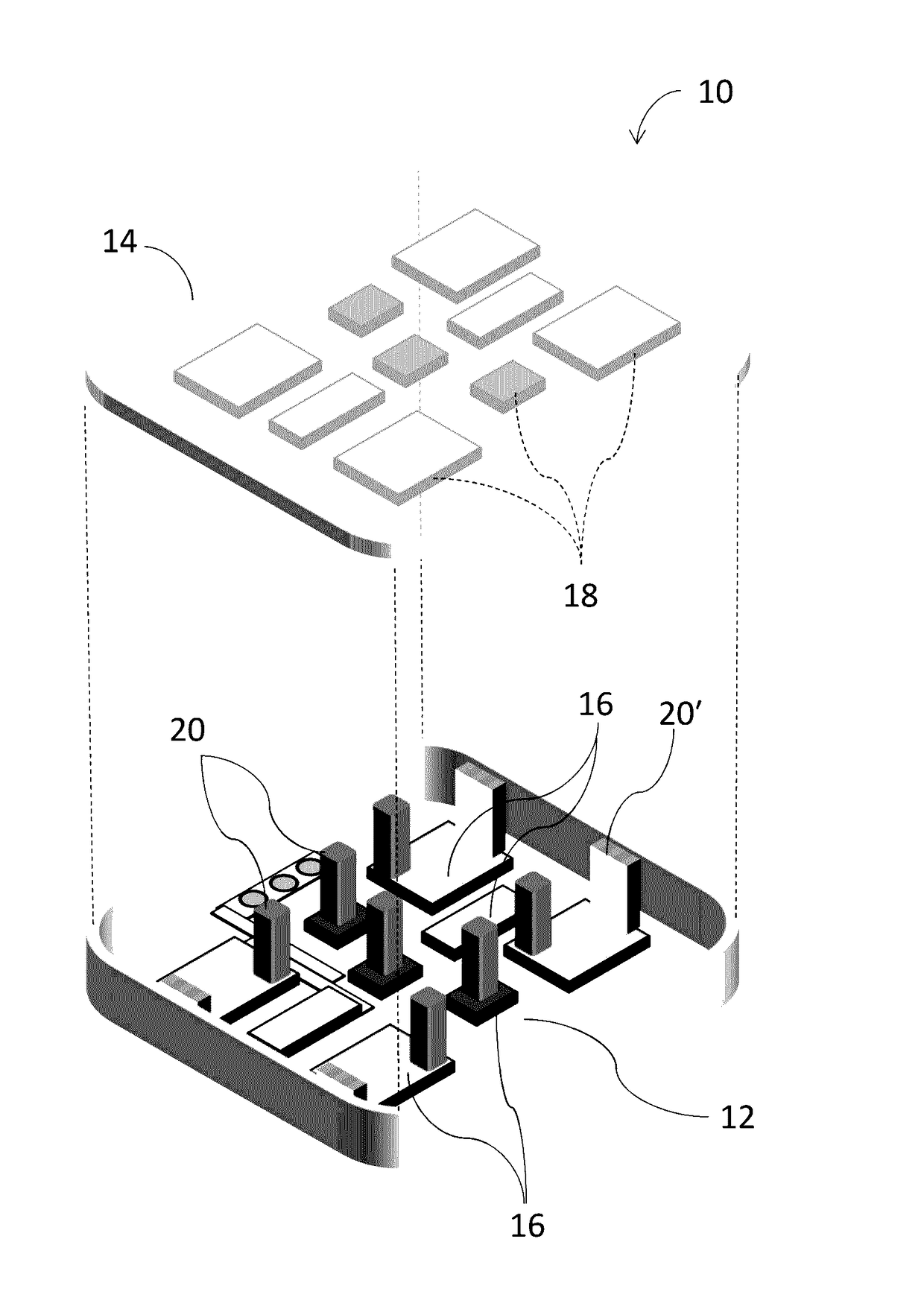

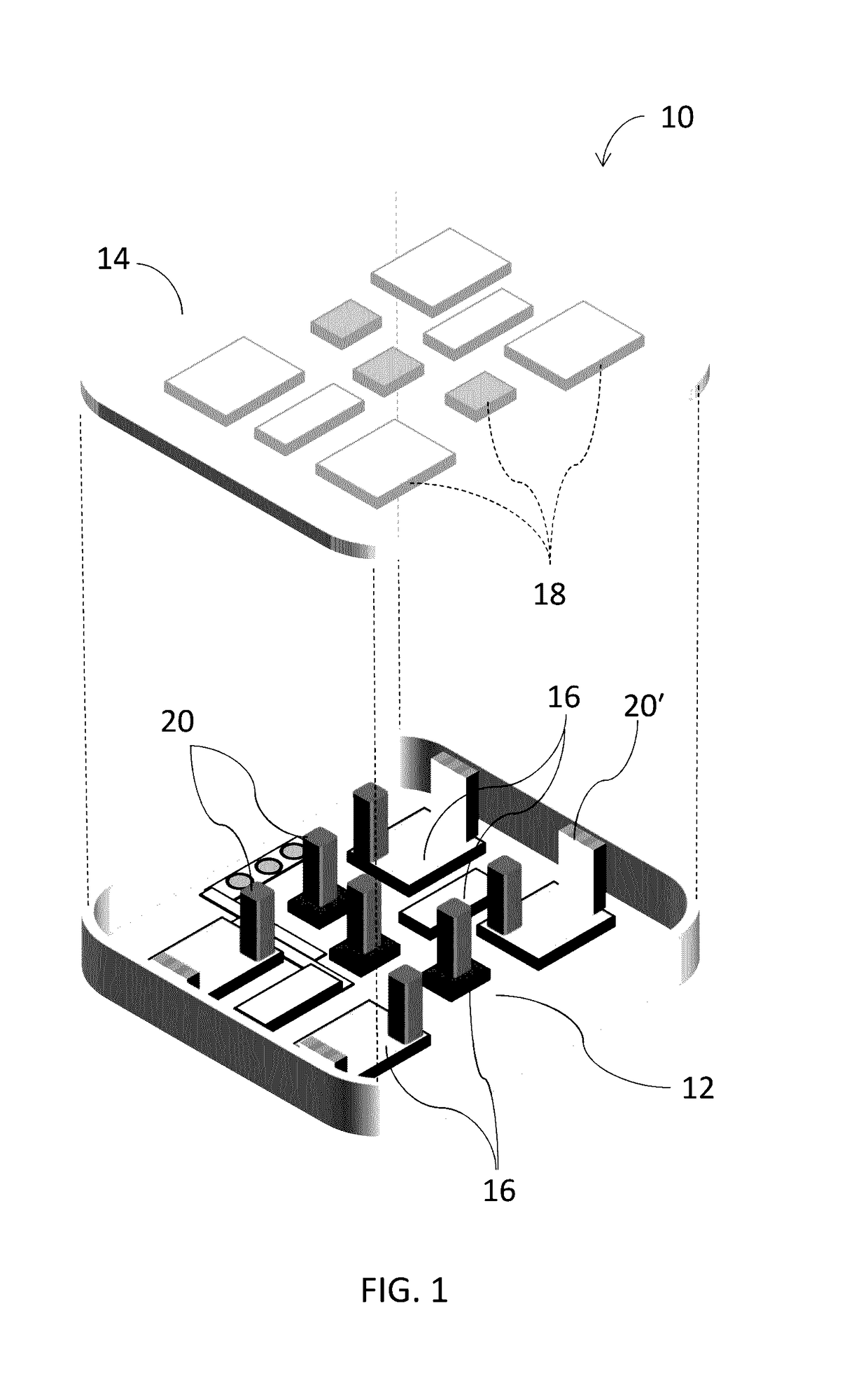

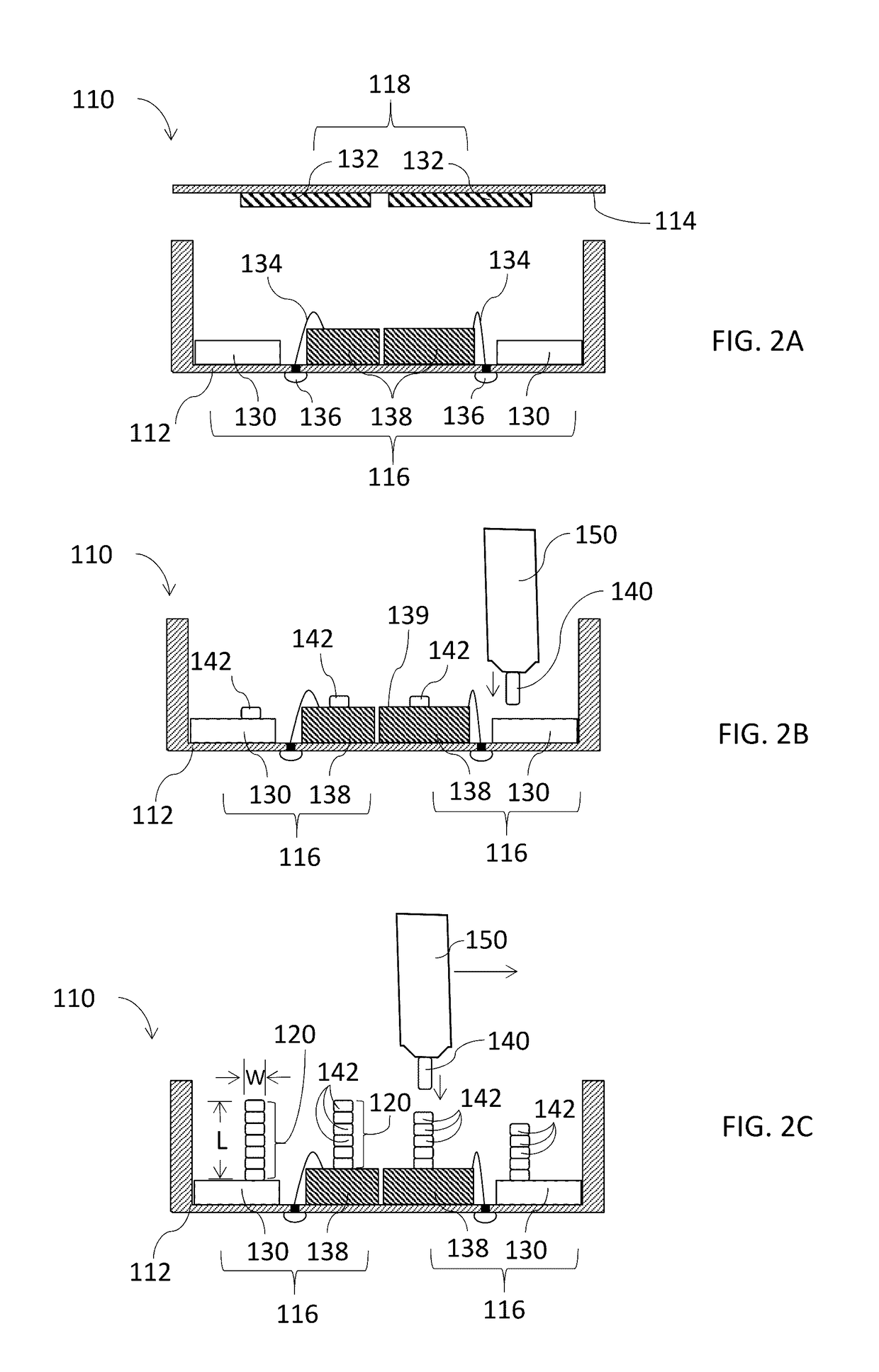

[0049]An electronic module, and method for making same, includes free-formed, self-supported interconnect pillars that electrically connect cover electronic components disposed on a cover substrate with base electronic components disposed on a base substrate. The free-formed, self-supported interconnect pillars may extend vertically in a straight path between the cover electronic components and the base electronic components. The free-formed, self-supported interconnect pillars may be formed from an electrically conductive filament provided by an additive manufacturing process.

[0050]The principles of the present invention have particular application to radio frequency (RF) electronic modules for wireless electronic devices, and thus will be described below chiefly in this context. It is also understood that principles of this invention may be applicable to other electronic modules where it is desirable to provide a three-dimensional architecture using free-formed, self-supported int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com