Sheet-like article, and method for producing same

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0183]Polyethylene terephthalate copolymerized with 8 mol % 5-sodium sulfoisophthalate was used as a sea component, and polyethylene terephthalate was used as an island component. The sea component and the island component were conjugated in a ratio of 20% by mass to 80% by mass to give sea-island type conjugated fibers having 16 islands per filament and an average fiber diameter of 20 μm. The sea-island type conjugated fibers obtained were cut into staple fibers 51 mm in length and passed through a card and a crosslapper to form a fiber web. The fiber web was processed into a nonwoven fabric by needle punching.

[0184]The nonwoven fabric thus obtained was shrunk by dipping in hot water at 97° C. for 5 minutes, and dried at 100° C. for 10 minutes. The resulting nonwoven fabric was then provided with an aqueous solution of a PVA (NM-14 available from Nippon Synthetic Chemical Industry), having a degree of saponification of 99% and a degree of polymerization of 1,400, the aqueous soluti...

example 2

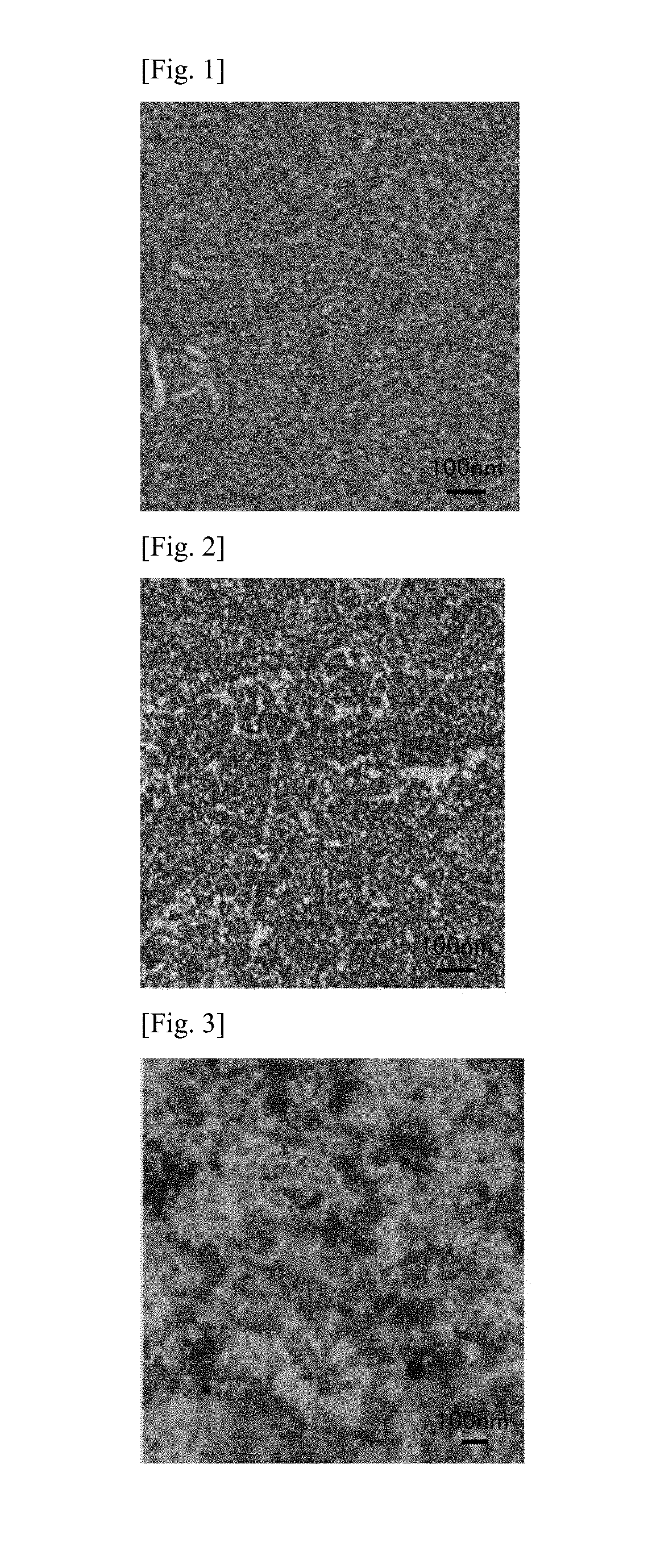

[0186]The same procedure as in Example 1 was repeated except that the sheet substrate was impregnated with a dispersion of the polyurethane resin composition B adjusted to have a solids concentration of 20%, an active ingredient of a blocked isocyanate (“Erastron” [registered trademark] BN-77 available from Dai-ichi Kogyo Seiyaku) in an amount of 6% based on solid polyurethane, and magnesium sulfate in an amount of 0.3 part by mass based on solid polyurethane, thereby obtaining a man-made leather with a unit weight of 222 g / m2. The man-made leather obtained had a good appearance and a touch without a paper-like feel. From the man-made leather, the polyurethane resin was collected and observed under an AFM. The parameter A was 4.2, and the polyurethane resin had a microphase-separated structure with HS domains and SS domains finely dispersed. In the microphase-separated structure observed, spherical HS domains mainly having a size of 100 nm or smaller were dispersed in uniform SS dom...

example 3

[0187]The same procedure as in Example 1 was repeated except that the sheet substrate was impregnated with a dispersion of the polyurethane resin composition C adjusted to have a solids concentration of 20%, an active ingredient of a carbodiimide crosslinking agent (“Carbodilite” [registered trademark] V02-L2 available from Nisshinbo Chemical) in an amount of 6% by mass based on solid polyurethane, and magnesium sulfate in an amount of 0.4 part by mass based on solid polyurethane, thereby obtaining a man-made leather with a unit weight of 252 g / m2. The man-made leather obtained had a good appearance and a touch without a paper-like feel. From the man-made leather, the polyurethane was collected and observed under an AFM. The parameter A was 2.2, and the polyurethane resin had a microphase-separated structure with HS domains and SS domains finely dispersed. In the microphase-separated structure observed, spherical HS domains mainly having a size of 100 nm or smaller were dispersed in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com