Capacitive biosensor for identifying a microorganism or determining antibiotic susceptibility

a biosensor and capacitive technology, applied in the field of capacitive biosensors, can solve the problems of requiring an excessive amount of labor and taking a long time, and achieve the effect of effective treatmen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

manufacturing example 1

nt

[0058]Cephalothin, chloramphenicol, Gentamicin, Ciprofloxacin, cefrtiaxone, and Tetracycline antibiotics were purchased from Sigma Aldrich (US), and various concentrations were prepared. Chloramphenicol was dissolved in ethanol, Ciprofloxacin was dissolved in DMSO, gentamycin and cephalothin were dissolved in distilled water, and Sephritaxone and Tetracycline were dissolved in ethanol.

[0059]The strains used in the experiment were E. coli, Acinetobacter baumannii, Staphylococcus aureus, Enterococcus faecalis, Enterococcus faecalis, as well as Ampicillin-resistant E. coli and Tetracycline-resistant E. coli.

example 2

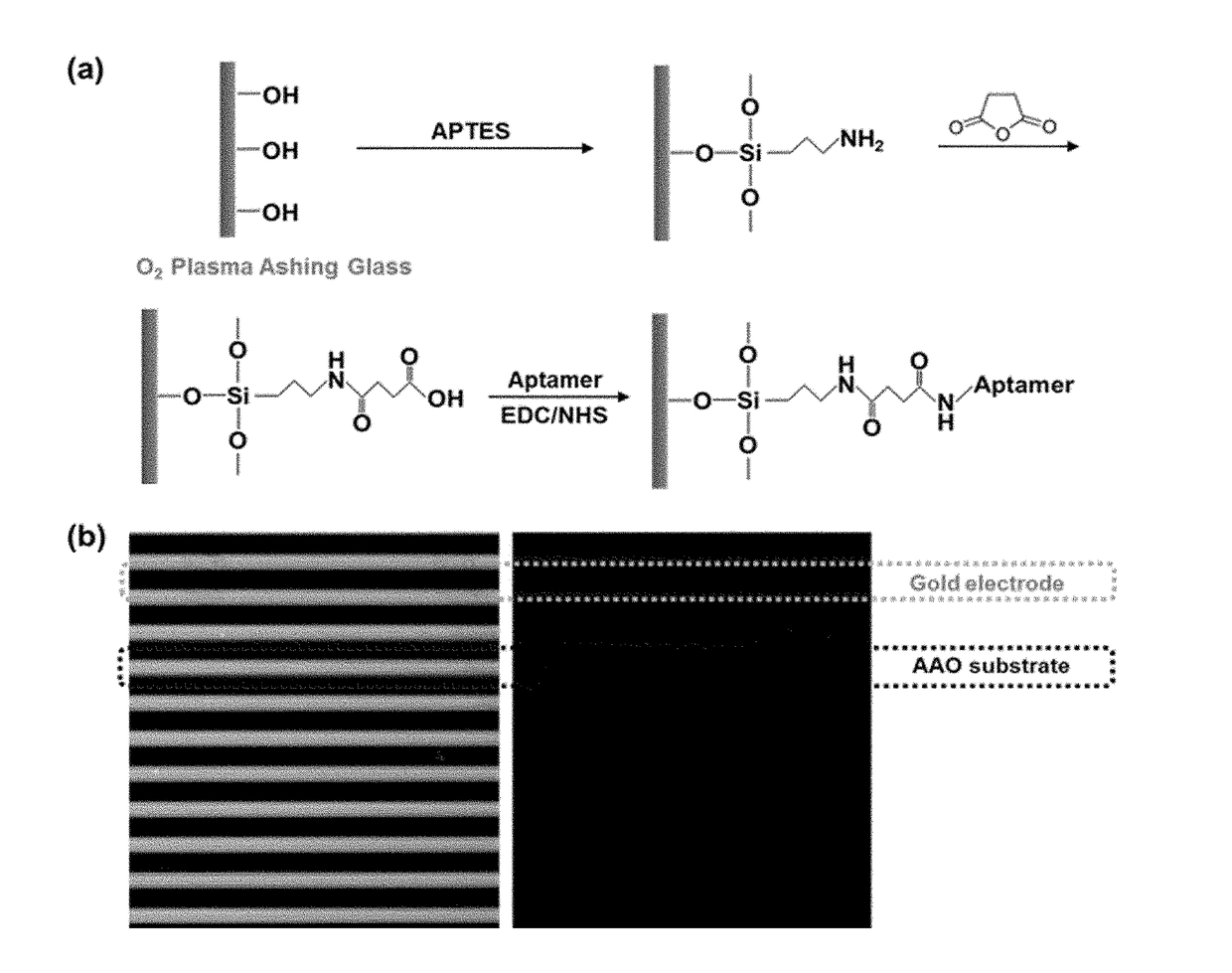

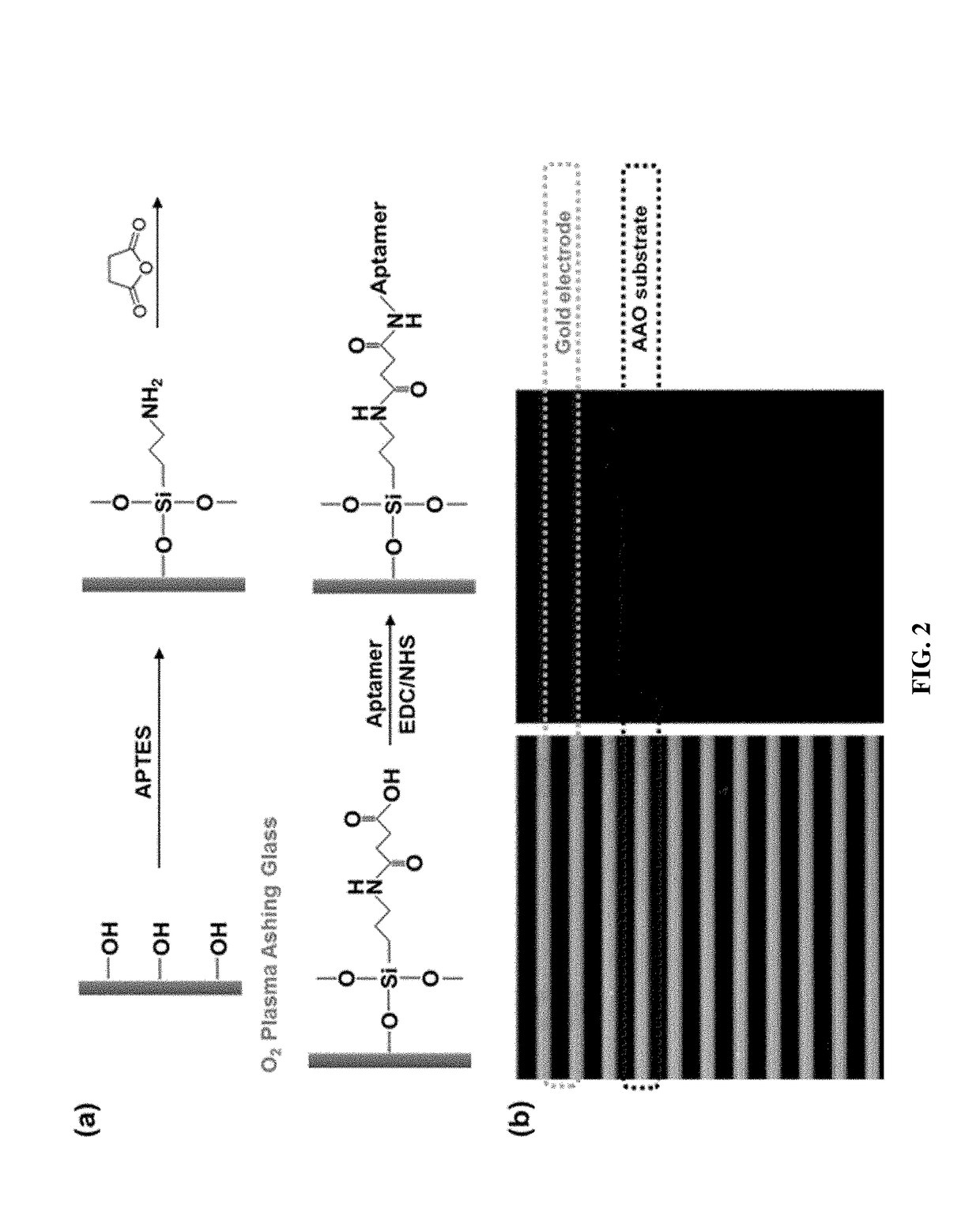

Manufacturing Manufacturing of Capacitive Biosensor

[0060]In order to manufacture a capacitive biosensor for detecting a microorganism, a sensor (Comparative Example 1) in which electrodes are formed on a glass substrate, a sensor (Comparative Example 2) which a glass electrode formatted and a aptamer-treated sensor, and a sensor (Example 1) treated with an aptamer to AAO were manufactured.

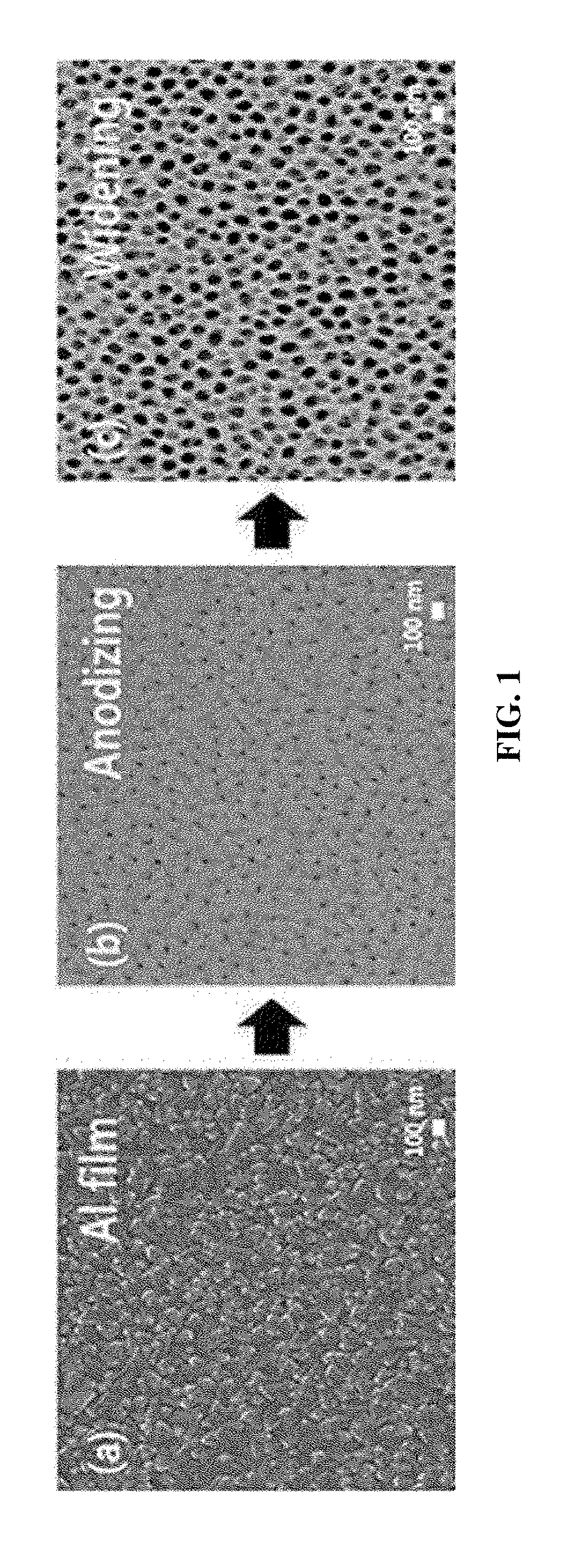

[0061]Particularly, the porous nanostructured plate (for example, AAO plate) was formed to have a thickness of Ti / Au / Al (100 / 20 / 1000 nm) on a 4-inch Si substrate with a 1 nm thick SiO2 layer grown thereon and a thickness of Ti / Au / Al (100 / 20 / 1000 nm).

[0062]Then, the porous nanostructured plate was immersed in oxalic acid while maintaining the temperature at 15° C. using a water bath and a chiller at a concentration of 0.3M of oxalic acid, and anodic oxidation was carried out by applying a DC current of 40V. After anodic oxidation, a widening reaction was performed to produce AAO having porous nanos...

experimental example 1

ement Performance of Capacitance Change of Sensor According to Substrate

[0066]A measurement performance of a capacitance change of a sensor was confirmed using the sensor manufactured according to manufacturing Example 2. Particularly, E. coli was treated for each of a sensor (Comparative Example 1) in which an electrode was formed on a glass substrate, a sensor (Comparative Example 2) in which a glass substrate was treated with an aptamer, and a sensor (Example 1) in which AAO was treated with an aptamer, and a change in capacitance was measured.

[0067]As shown in FIG. 5, when the capacitance is measured using the sensor of the present disclosure, the change in capacitance is increased as the bacterium binds / propagates, the change in capacitance of all three treatment groups was measured, in the case of the AAO+aptamer sensor of Example 1 as compared to the glass substrate sensor (black) of Comparative Example 1 and the glass substrate sensor (red) treated with the aptamer of Compar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| distance | aaaaa | aaaaa |

| spacing distance | aaaaa | aaaaa |

| spacing distance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com