Carbon fiber manufacturing apparatus

a technology of carbon fiber and manufacturing apparatus, which is applied in the field of carbon fiber manufacturing apparatus, can solve the problems of insufficient adhesion of untreated carbon fiber to matrix resin, poor transverse properties such as separation strength and shear strength, and excessive fine formation of carbon fiber surface, so as to reduce the cost of carbon fiber production equipment and the effect of reducing the working time and greatly improving the size quality of carbon fiber

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035]Embodiments of the present invention will now be described, by way of example only, with reference to the accompanying drawings.

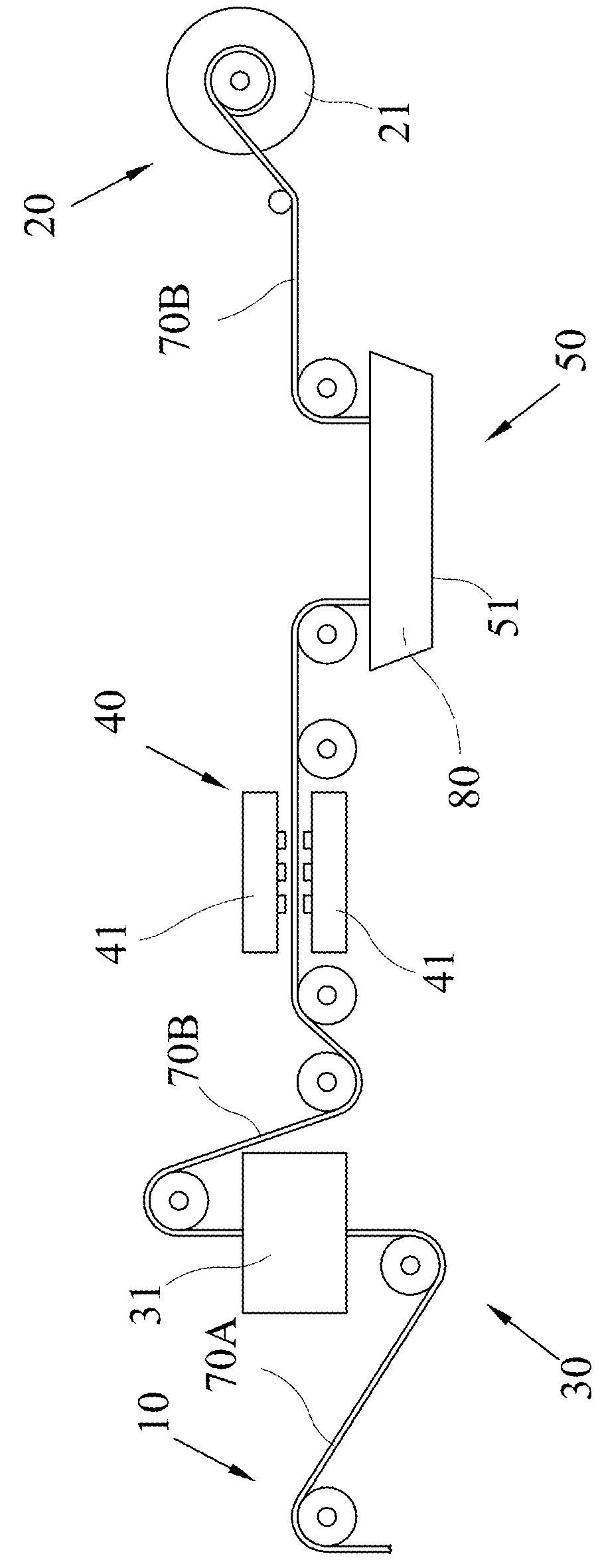

[0036]The present invention discloses a carbon fiber manufacturing apparatus which can greatly improve the sizing quality of carbon fibers and effectively reduce the cost of the carbon fiber production equipment and the working time. As shown in FIG. 1, the carbon fiber manufacturing apparatus of the present invention comprises a feeding module 10, a receiving module 20, a high-temperature carbonization module 30, a plasma surface treatment module 40, and a sizing module 50.

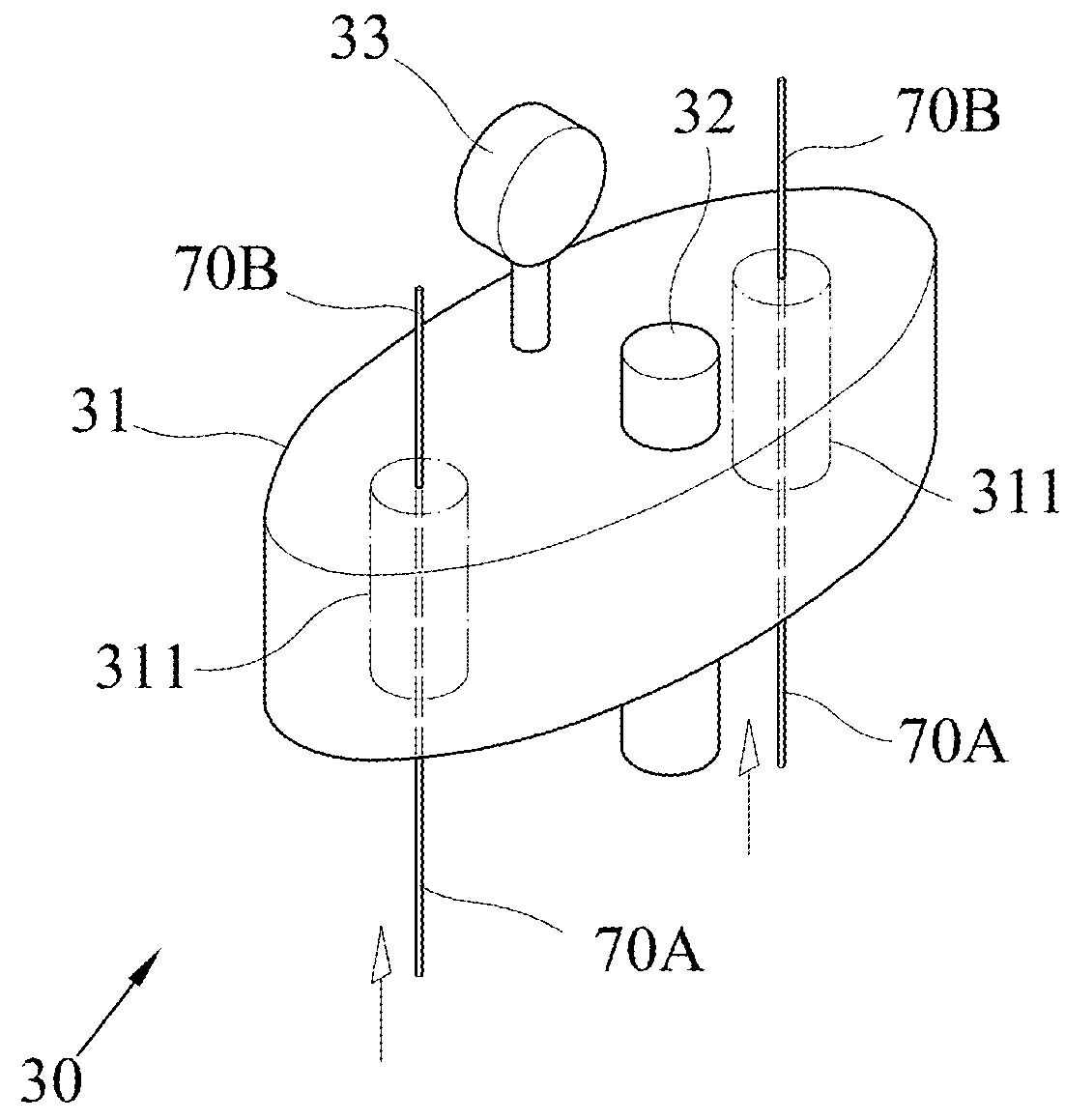

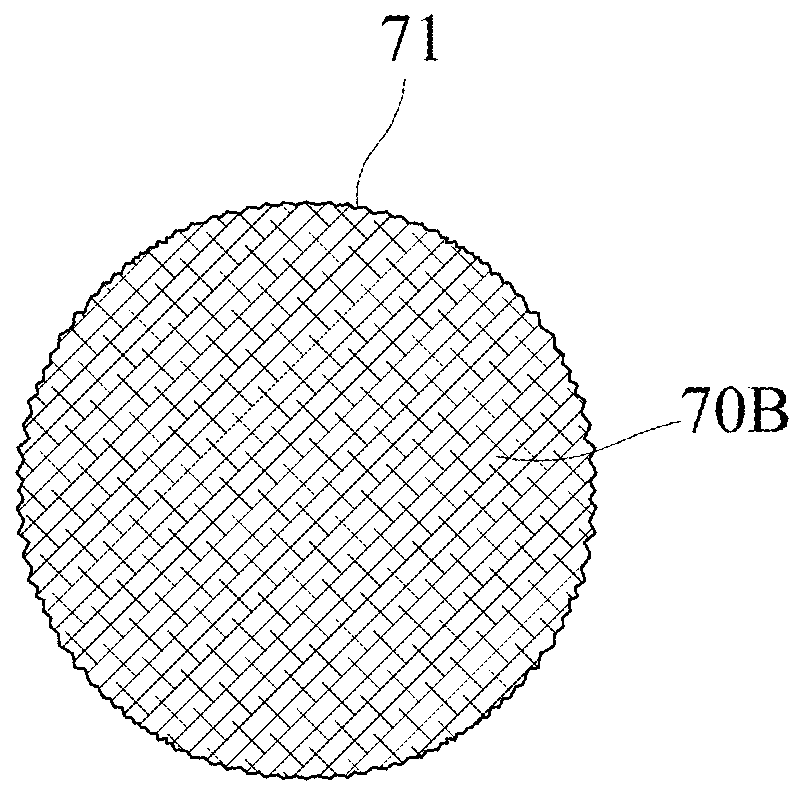

[0037]Referring to FIG. 1 to FIG. 4, the feeding module 10 is used to supply a carbon fiber precursor fiber bundle 70A to be processed into a carbon fiber 70B. In practice, the carbon fiber precursor fiber bundle 70A may be formed of rayon, poly vinyl alcohol, vinylidene chloride, polyacrylonitrile (PAN), pitch, and the like. The surface of the carbon fiber precursor fiber bundle 7...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Power | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com