Method for cultivating biofloc and method for using biofloc in aquaculture

A technology of biological floc and cultivation method, applied in the direction of microorganism-based methods, biochemical equipment and methods, biological water/sewage treatment, etc., can solve the problems of feeding, increasing time cost, high cost, etc., to improve absorption utilization rate, The effect of reducing the cost of carbon source and reducing the cost of bait

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] A method for cultivating bioflocs, comprising the steps of:

[0023] 1) Select the dried wheat straw, crush the straw with a pulverizer, and then screen it with a 20-mesh screen to obtain straw particles with a particle size of less than 0.1 mm;

[0024] 2) Mix the above-mentioned straw granules with cornstarch and water evenly according to the mass ratio of 10:0.5:1.5, and extrude the mixture with an extrusion extruder, control the temperature of the extrusion cavity of the extrusion extruder at 120°C, and The pulverizer crushes the expanded mixture particles into solid particles with a particle size of 0.5 mm;

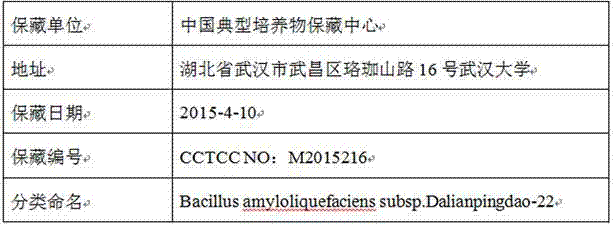

[0025] 3) Mix the above-mentioned solid particles and culture water in the culture unit according to the volume ratio of 1.1:1, and then add the bacillus named Dalianpingdao-22 and the preservation number CCTCC M 2015216 into the culture unit, so that the culture unit The number of live bacillus is 3×10 10 cfu / L, maintain the dissolved oxygen in the water in...

Embodiment 2

[0030] A method for cultivating bioflocs, comprising the steps of:

[0031] 1) Choose the rice straw that has been dried in the sun, crush the straw with a pulverizer, and then screen it with a 20-mesh screen to obtain straw particles with a particle size of less than 0.1mm;

[0032] 2) Mix the above-mentioned straw granules with cornstarch and water evenly according to the mass ratio of 9:0.5:1.5, and use an extruder to puff the mixture. The pulverizer crushes the expanded mixture particles into solid particles with a particle size of 0.45mm;

[0033] 3) Mix the above-mentioned solid particles and culture water in the culture unit according to the volume ratio of 1:1, and then add the bacillus named Dalianpingdao-22 and the preservation number of CCTCC M 2015216 into the culture unit, so that the culture unit The number of viable bacillus is 2×10 10 cfu / L, maintain the dissolved oxygen in the water in the culture unit at 6-8 mg / L, and collect bioflocs when the total suspend...

Embodiment 3

[0038] A method for cultivating bioflocs, comprising the steps of:

[0039] 1) Choose corn stalks that have been dried in the sun, crush the stalks with a pulverizer, and then screen them with a 20-mesh sieve to obtain straw particles with a particle size of less than 0.1mm;

[0040] 2) Mix the above-mentioned straw granules with cornstarch and water evenly according to the mass ratio of 11:0.5:1.5, and extrude the mixture with an extrusion extruder, control the temperature of the extrusion cavity of the extrusion extruder at 130°C, and then The pulverizer crushes the expanded mixture particles into solid particles with a particle size of 0.55mm;

[0041] 3) Mix the above-mentioned solid particles and culture water in the culture unit according to the volume ratio of 1.2:1, and then add the bacillus named Dalianpingdao-22 and the preservation number CCTCC M 2015216 into the culture unit, so that the culture unit The number of live bacillus is 5×10 10 cfu / L, maintain the diss...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com