Multilayer ceramic capacitor and manufacturing method of multilayer ceramic capacitor

a manufacturing method and multi-layer ceramic technology, applied in the direction of fixed capacitors, stacked capacitors, fixed capacitor details, etc., can solve the problem of not defined donor elements in the dielectric layer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment

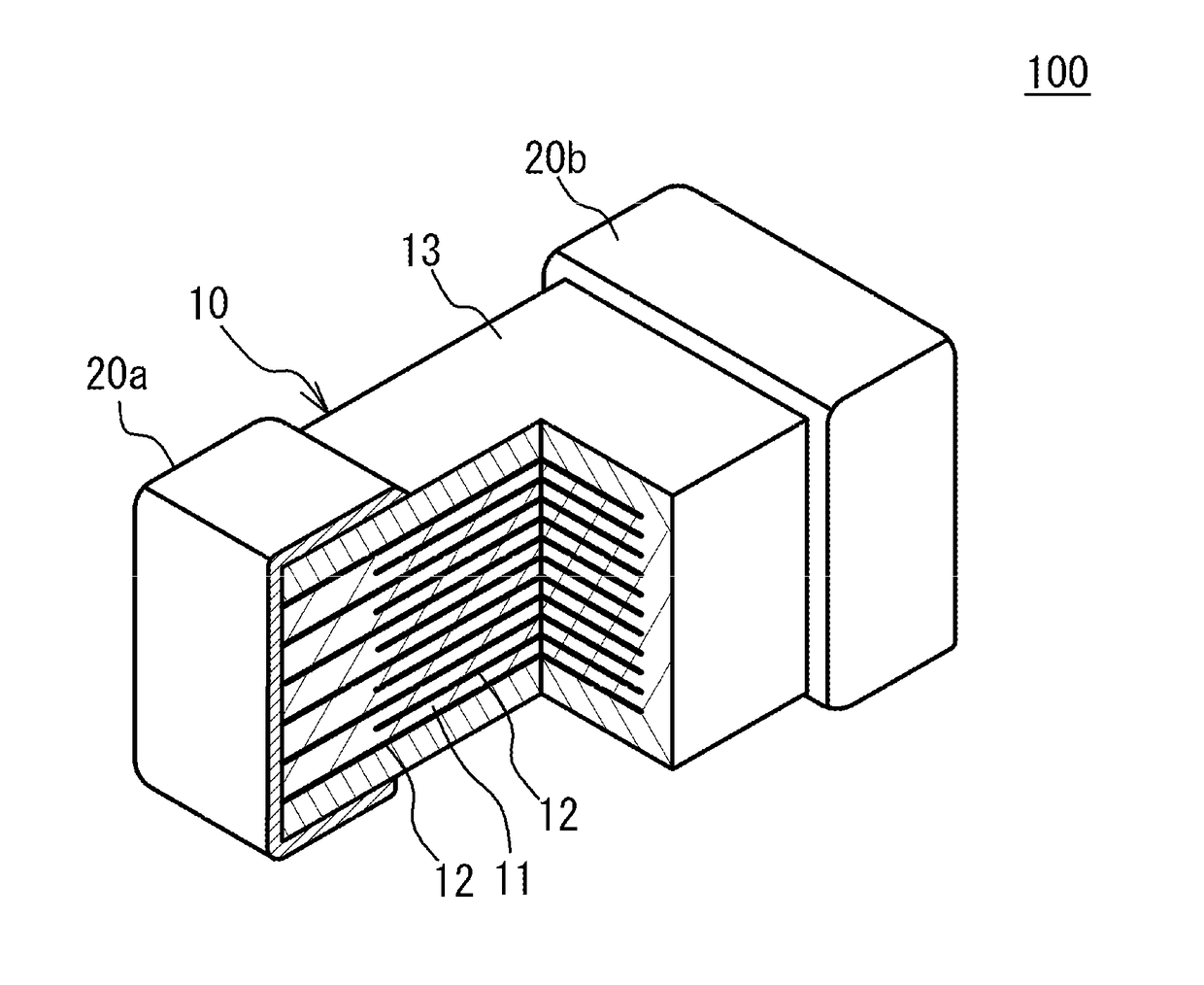

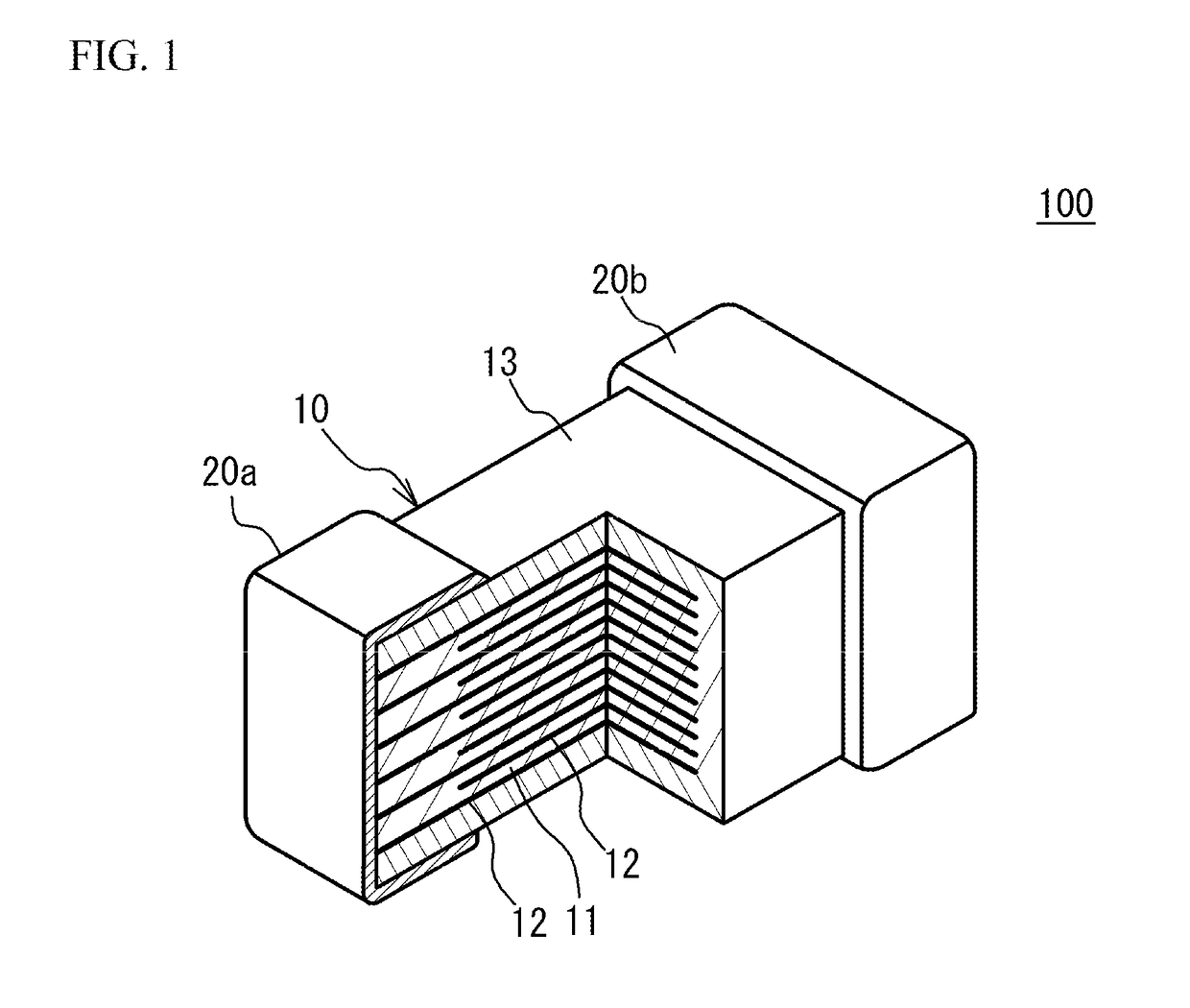

[0015]FIG. 1 illustrates a partial perspective view of a multilayer ceramic capacitor 100 in accordance with an embodiment. As illustrated in FIG. 1, the multilayer ceramic capacitor 100 includes a multilayer chip 10 having a rectangular parallelepiped shape, and a pair of external electrodes 20a and 20b that are respectively provided at two edge faces of the multilayer chip 10 facing each other. In four faces other than the two edge faces of the multilayer chip 10, two faces other than an upper face and a lower face of the multilayer chip 10 in a stacking direction are referred to as side faces. The external electrodes 20a and 20b extend to the upper face, the lower face and the two side faces. However, the external electrodes 20a and 20b are spaced from each other.

[0016]The multilayer chip 10 has a structure designed to have dielectric layers 11 and internal electrode layers 12 alternately stacked. The dielectric layer 11 includes ceramic material acting as a dielectric material. ...

example 1

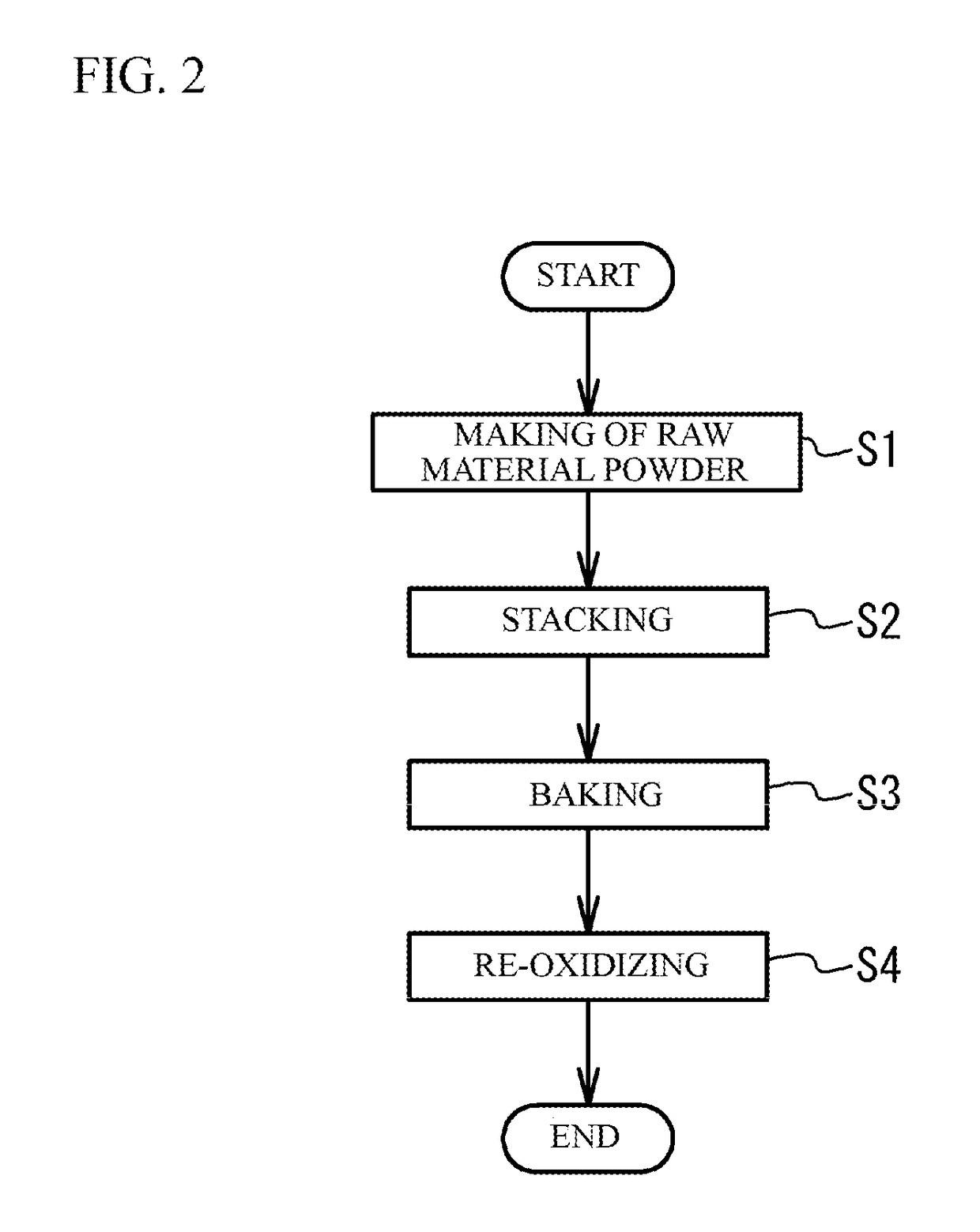

[0036]In an example 1, barium titanate was used as the main component ceramic of the dielectric layer 11. Mo was used as the donor element. MoO3 was added to the main component ceramic powder so that Mo is 0.2 atm % on a presumption that Ti of the main component ceramic powder is 100 atm %. The resulting main component ceramic powder was sufficiently wet-blended and crushed with a ball mil. Thus, the dielectric material was obtained. An organic binder and a solvent were added to the dielectric material. And dielectric green sheets were made by a doctor blade method. The organic binder was polyvinyl butyral (PVB) resin or the like. The solvent was ethanol, toluene or the like. And a plasticizer and so on were added. Next, the conductive paste for forming the internal electrode layer 12 was made by mixing powder acting as a main component metal of the internal electrode layer 12, a binder, a solvent and an additive as needed. The organic binder and the solvent were different from thos...

example 2

[0037]In an example 2, a main component ceramic powder in which 0.05 atm % of Mo was solid-solved in advance was used as the dielectric material. A Mo source was not added to the main component ceramic powder. Other conditions were the same as those of the example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap