Method of production of high-pressure seamless cylinder from corrosion-resistant steel

a production method and technology of steel, applied in the field of material forming, can solve the problems of inability to produce safe high-pressure seamless cylinders, inability to manufacture double-necked cylinders of a simple shape, considerable disadvantage, etc., and achieve the effects of reducing the mass of high-pressure cylinders, high mechanical resistance, and saving materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

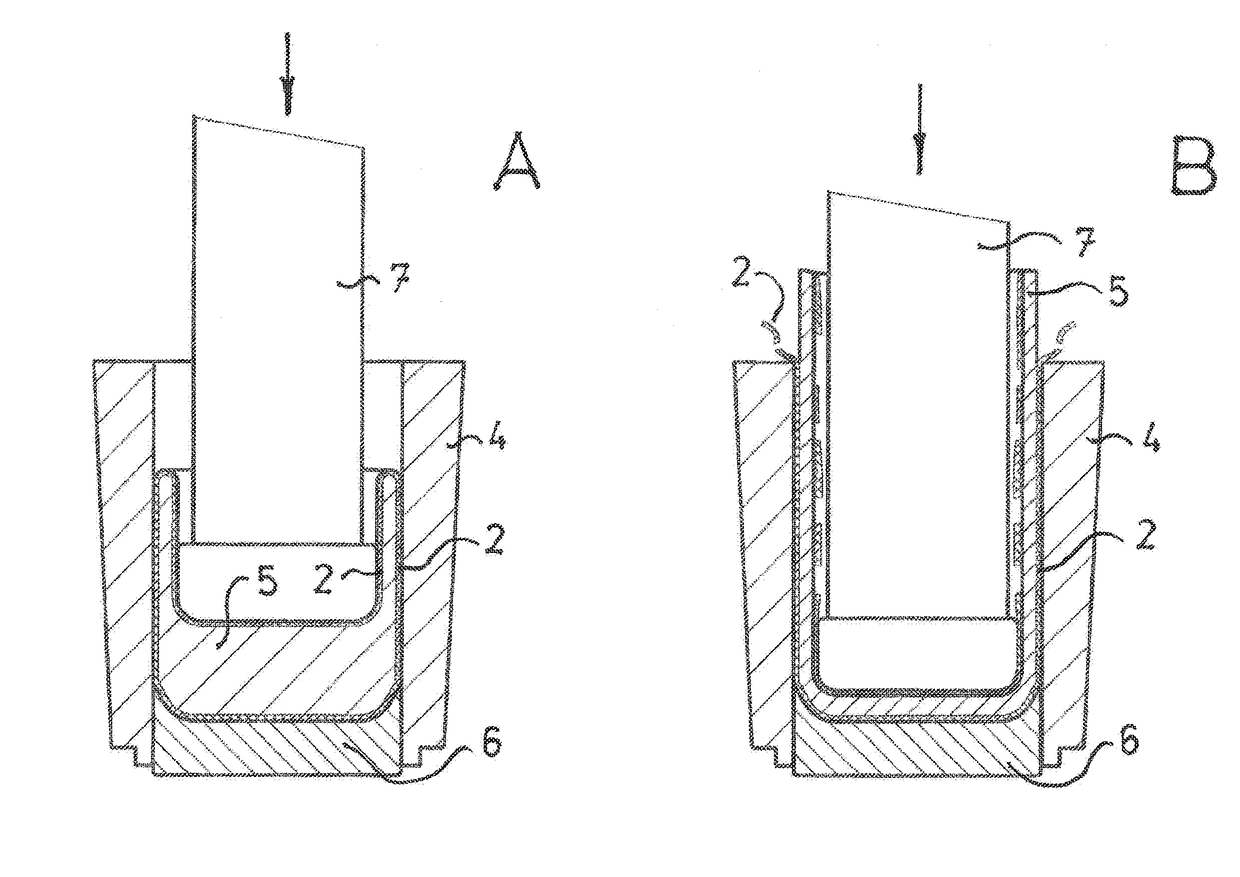

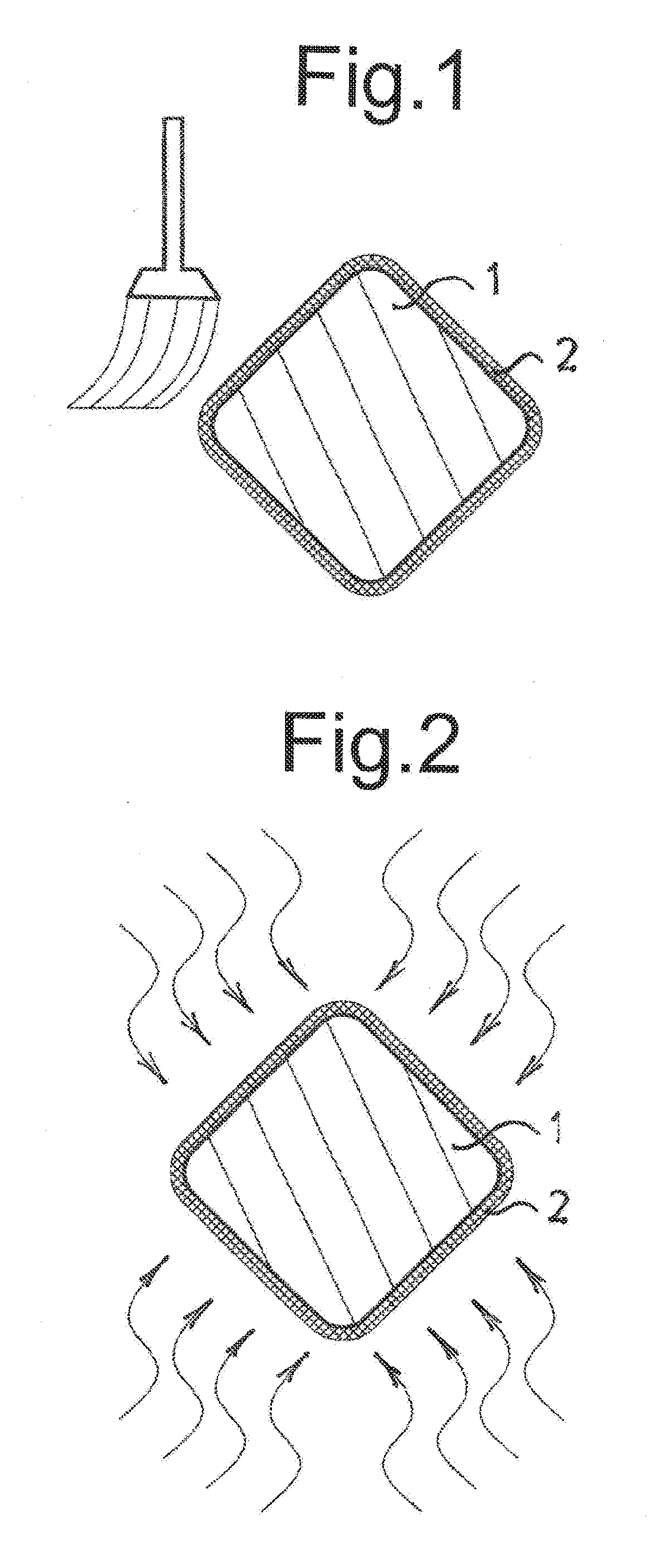

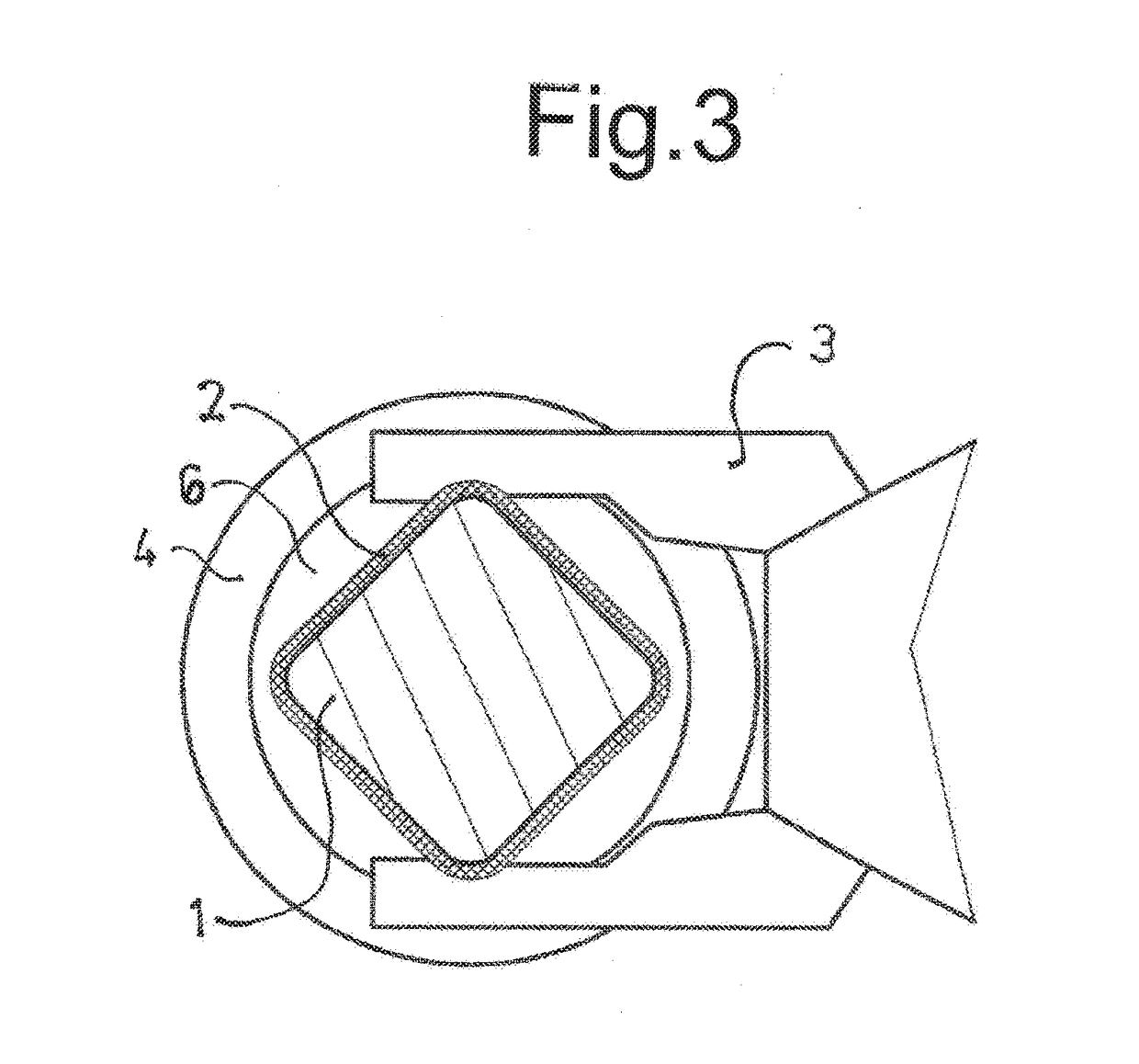

[0022]Example of embodiment of the invention is visually demonstrated with the help of FIGS. 1 to 4 and the hereinafter-described method of production of corrosion-resistant high-pressure seamless cylinder for storage, transport, and use of natural gas.

[0023]Parts of the size needed for the manufacture of cylinders of the produced volume are first cut from billets of corrosion-resistant steel having square or circular section. Each individual part, i.e. the starting steel blank 1, is on at least 85% of its surface coated with coating 2 from material based on water glass. The thickness of applied layer is 20 to 150 μm. Suspension usually called water glass is used as the material based on water glass. For the purposes of the invention, the suspension based on water glass stands for suspension containing 20 to 40% w. w. of sodium silicate or potassium silicate or their mixture and 80 to 40% w. w. of water. Admixtures of borosilicates and corrosion inhibitors such as hexamine, fenyleth...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com