Two-sectioned back-pressured catalytic converter

a back-pressured, catalytic converter technology, applied in the direction of engines, mechanical equipment, machines/engines, etc., to achieve the effect of reducing the pressure and temperature of the carrier and improving the discharge efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

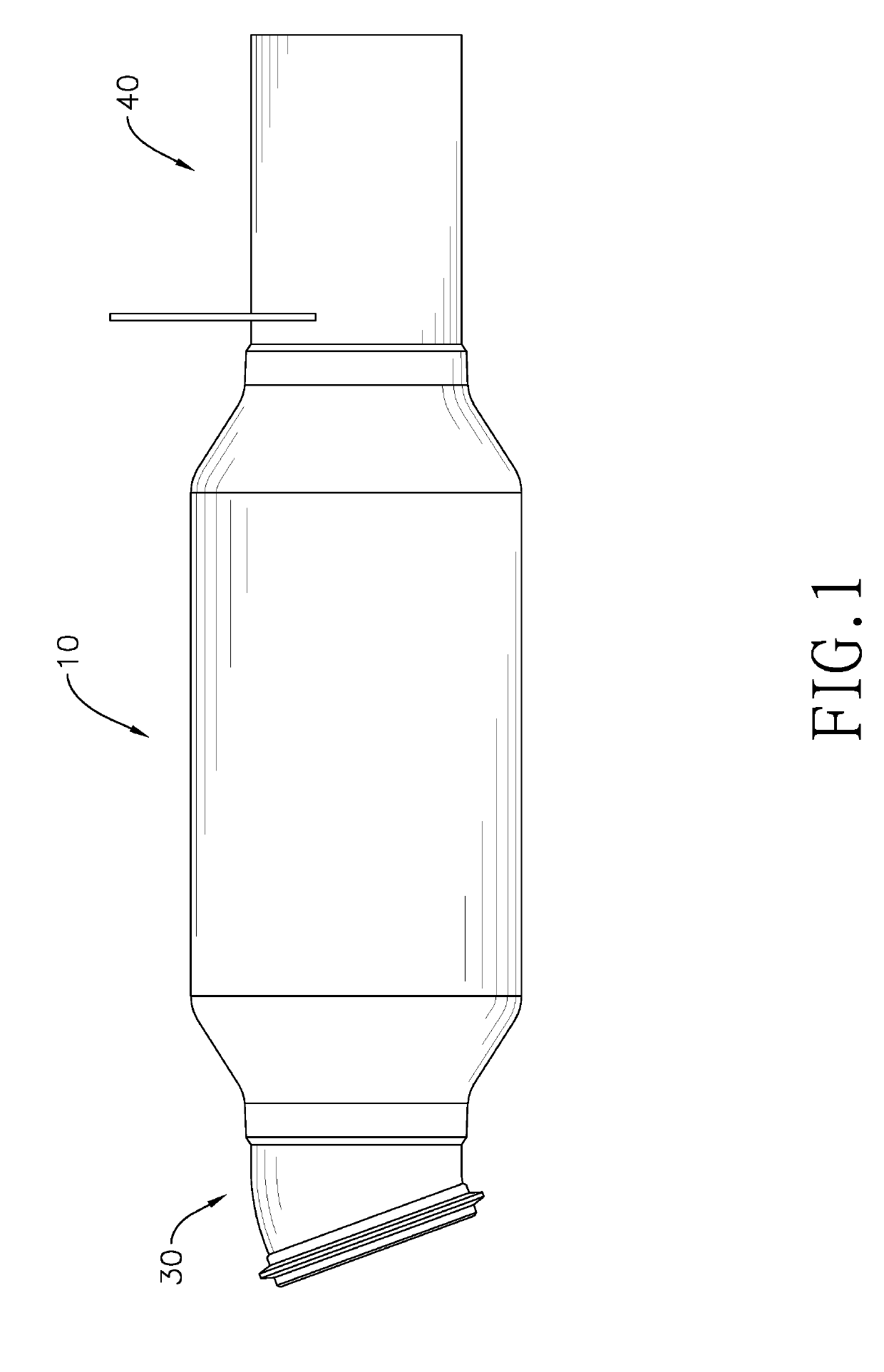

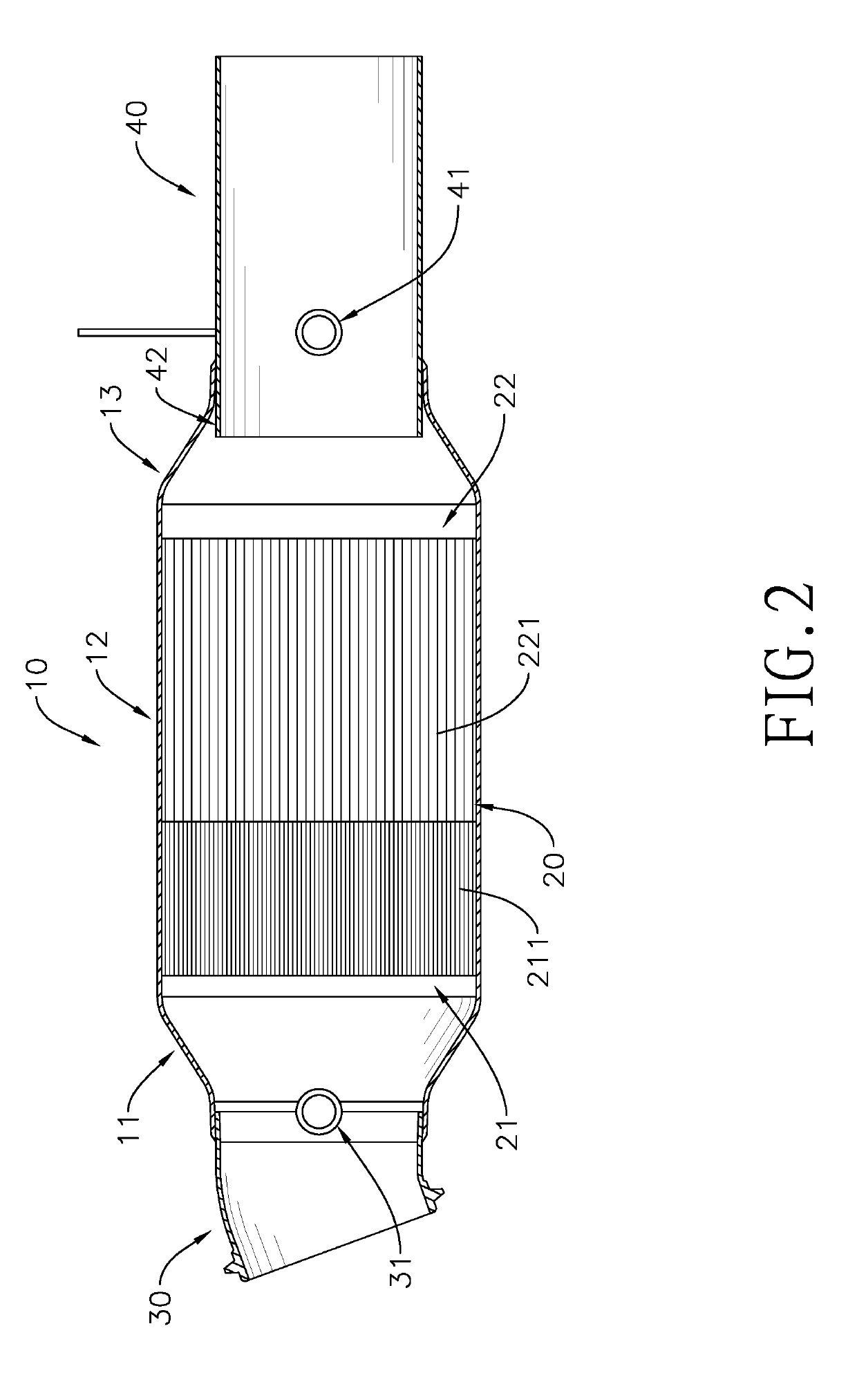

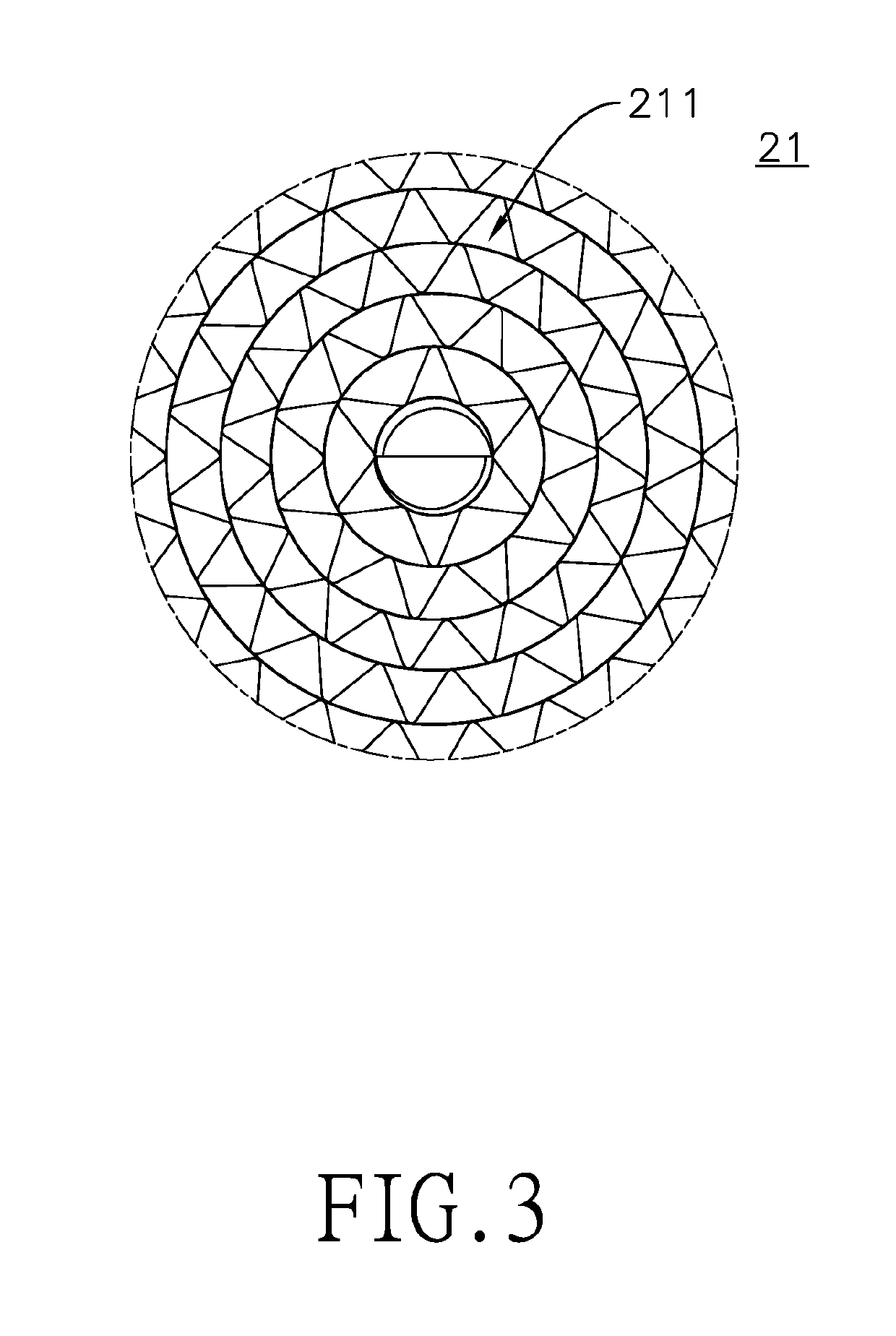

[0017]With reference to FIGS. 1 and 2, a two-sectioned back-pressured catalytic converter in accordance with the present invention comprises a main body 10, a honeycomb carrier 20, a connecting tube 30, and a tail tube 40.

[0018]The main body 10 is hollow and has an intake opening and an exhaust opening. In a preferred embodiment, the main body 10 further comprises an expanding section 11, a carrier section 12, and a tapered section 13 which are sequentially connected to one another. An opening of the expanding section 11 is said intake opening, and an inner diameter of the expanding section 11 progressively increases from the intake opening to the carrier section 12. An opening of the tapered section 13 is said exhaust opening, and an inner diameter of the tapered section 13 progressively decreases from the carrier section 12 to the exhaust opening. But an inner diameter of the main body 10 is not limited to the above mentioned, as the main body 10 can be implemented without the exp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com