Separated chambers pyrolysis furnace

a pyrolysis furnace and separate chamber technology, applied in the direction of combustible gas production, lighting and heating apparatus, combustion types, etc., can solve the problems of lowering the caloric power of syngas and mixing it with syngas, and achieve the effect of reducing the caloric power of syngas and particularly advantageous production of syngas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

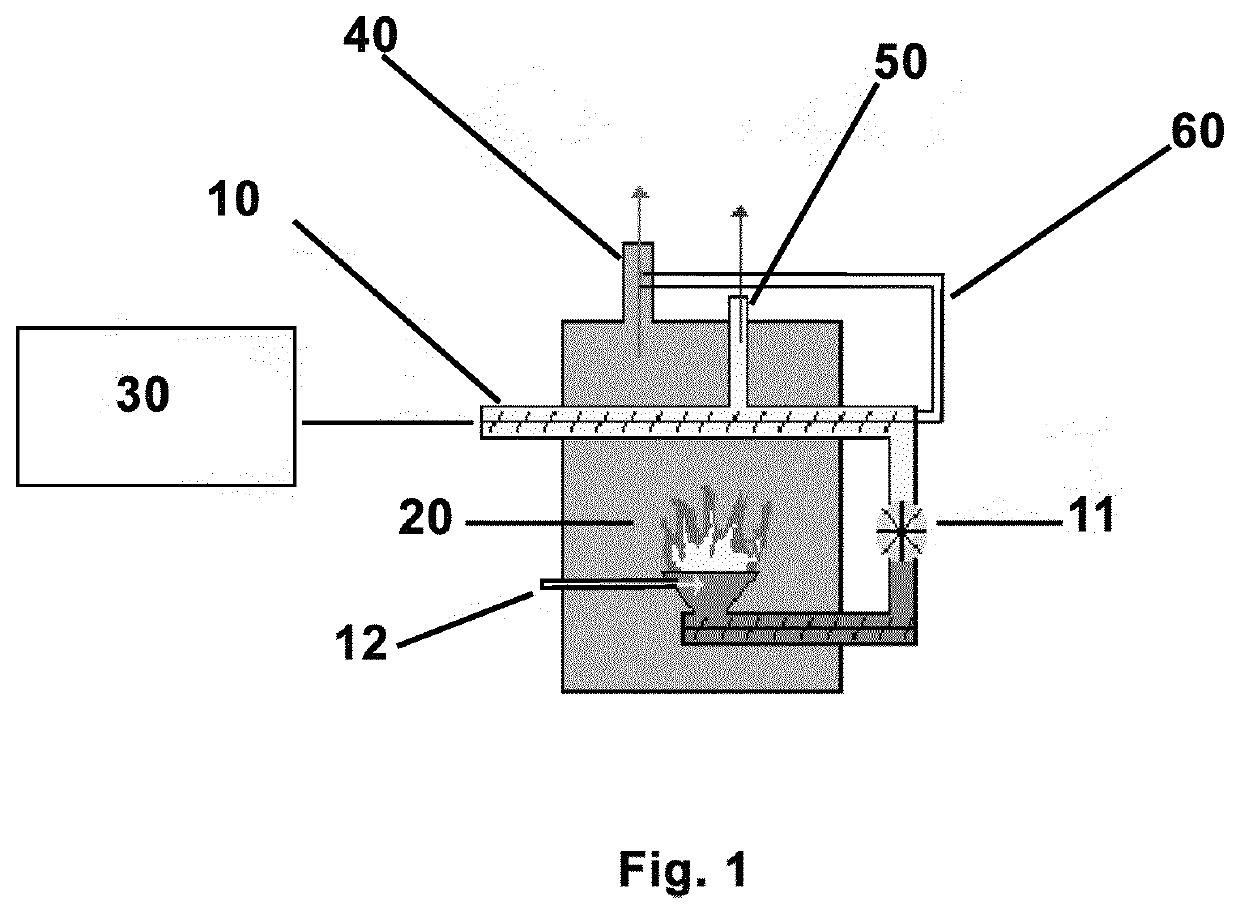

[0004]FIG. 1 shows a scheme of an embodiment of the two-chamber reactor according to the invention. The first chamber, i.e. the pyrolysis chamber (10), is formed by a pipe containing a cochlea (10) The fuel (e.g. woodchips) is fed through the cochlea and moves forward thanks to the movement of the cochlea. During the stay in the pyrolysis chamber (10), the fuel is heated by the combustion gases of the second chamber (20). The heating of woodchip in the first chamber at a suitable temperature and in the absence of oxygen produces pyrolysis of woodchip itself.

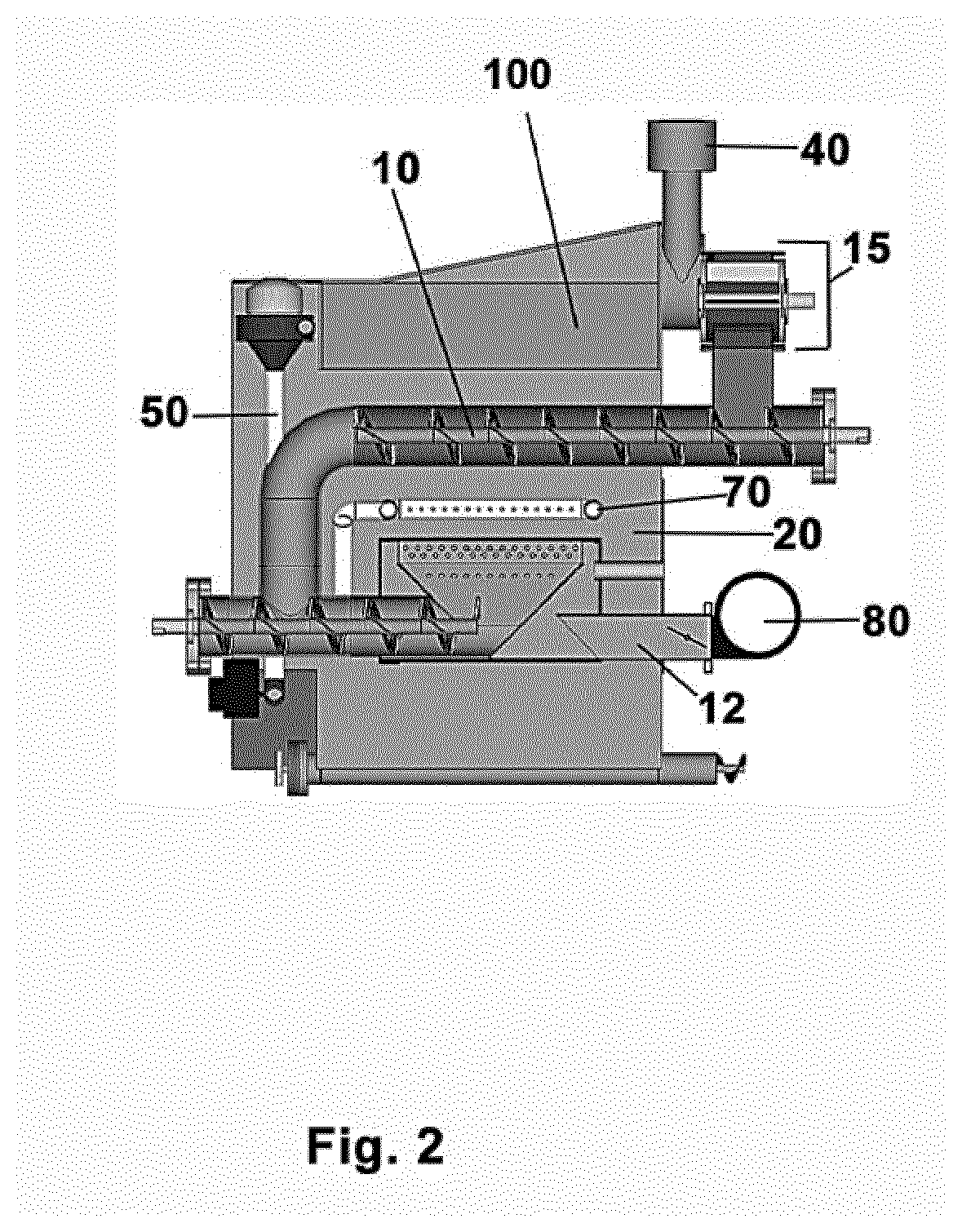

[0005]FIG. 2 represents a second embodiment of the invention wherein the fuel is fed to the pyrolysis chamber by star valve (15), and the passage from the first chamber (10) to the second chamber (20) takes place by gravitation. In this embodiment, syngas is withdrawn at the top of the loop where pyrolyzed fuel falls into the combustion chamber, and there is no need for a pipe (60) since no depression is created in this embodimen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com