Vapor deposition mask, vapor deposition method, and production method for organic el display device

a technology of organic el and vapor deposition mask, which is applied in the direction of vacuum evaporation coating, electroluminescent light sources, coatings, etc., can solve the problems of being subjected to etching, and achieve the effect of enduring a large stress, sufficient rigidity, and sufficient rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

third embodiment

[0093]A method for manufacturing an organic EL display apparatus according to the present invention comprises: forming a TFT (not shown), a planarizing layer, and a first electrode 22 (for example, an anode) on a supporting substrate 21; overlapping the supporting substrate 21 and a vapor deposition mask 1 such that the first electrode 22 is oriented downward and aligning them; and, vapor depositing a vapor deposition material 51, wherein a deposition layer 25 of an organic layer is formed by using the previously-described vapor deposition method. In this way, a second electrode 26 (a cathode, for example) is formed on the deposition layer 25.

[0094]While the supporting substrate 21 such as a glass plate, for example, is not shown fully, a driving element such as a TFT is formed for a R, G, B sub-pixel of each pixel, and the first electrode 22 that is connected to the driving element is formed on the planarizing layer by a combination of an ITO layer and a layer of metal such as Ag o...

first embodiment

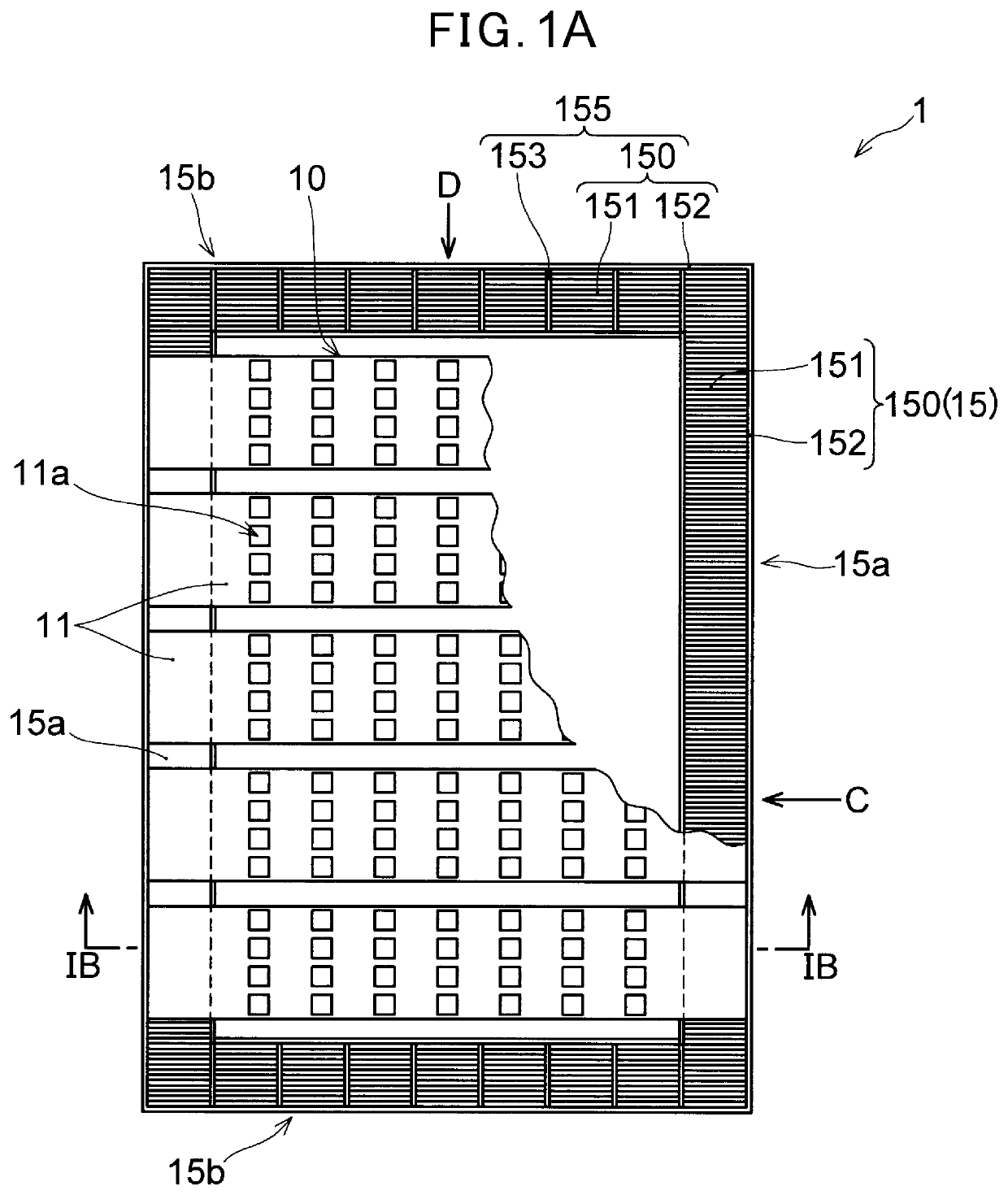

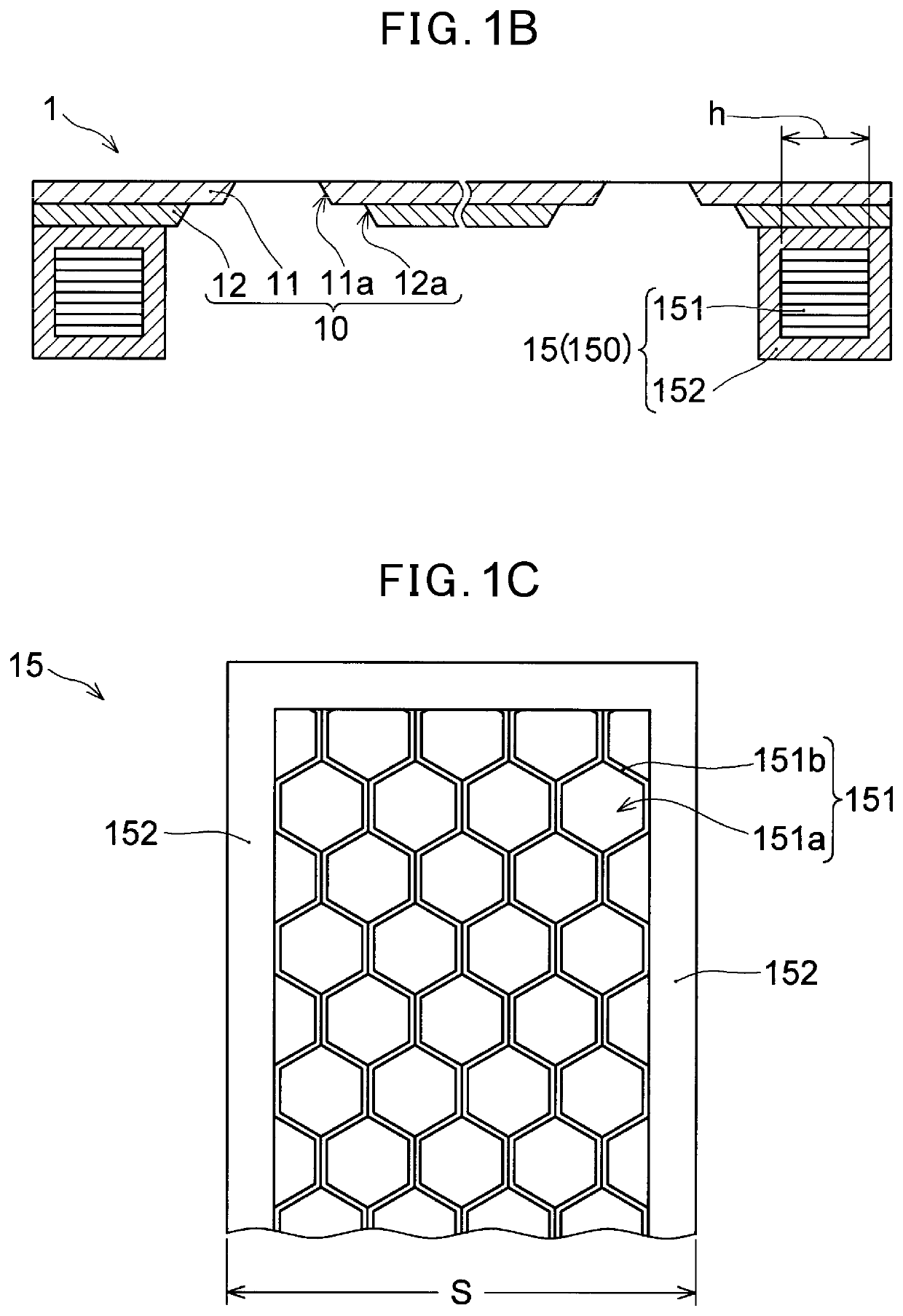

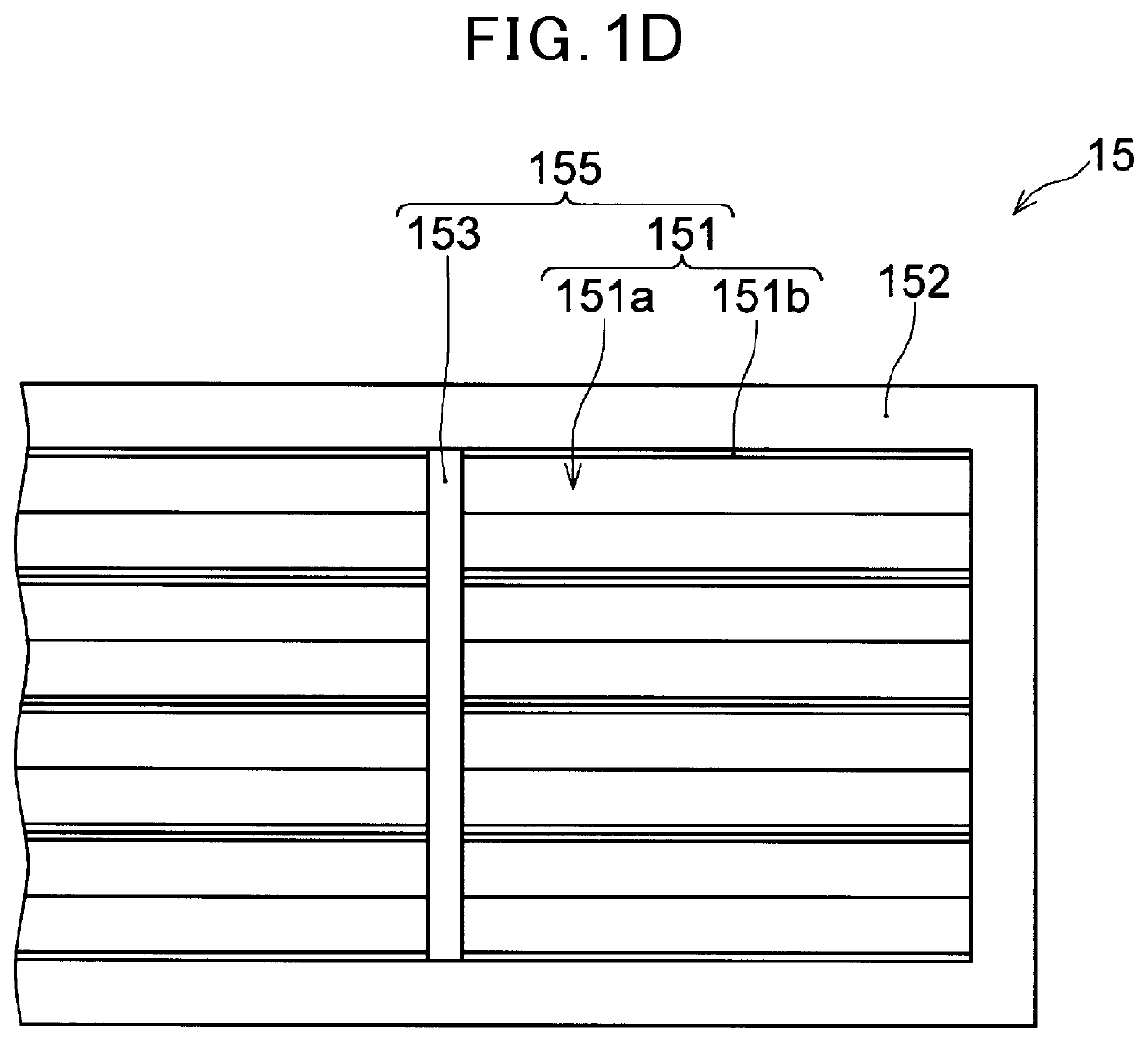

[0099](1) A vapor deposition mask according to the present invention comprises: a mask body at which an aperture pattern is formed; and a frame to which at least a part of a peripheral edge of the mask body is joined to hold the mask body at a certain state, wherein at least a part of the frame is formed by a columnar-shaped body in which unit structure bodies are stacked via a connecting end plate, each of the unit structure bodies comprising a core portion encompassing a vacant space therein and end plates provided on opposite end surfaces of at least a part of the core portion, thereby forming a sandwich structure.

[0100]The vapor deposition mask according to the first embodiment of the present invention can endure even a very large stress without buckling since a columnar-shaped body is formed by stacking unit structure bodies of a sandwich structure even in a case that a large stress acts in the axial direction of the frame while the frame of the vapor deposition mask is configu...

second embodiment

[0109](10) A method of vapor deposition according to the present invention comprises: arranging a substrate to be vapor deposited and the vapor deposition mask as described in one of (1) to (9) such that the substrate to be vapor deposited and the vapor deposition mask overlap each other; and, depositing a vapor deposition material onto the substrate to be vapor deposited by flying away the vapor deposition material from a vapor deposition source arranged at a distance from the vapor deposition mask.

[0110]In the vapor deposition method according to the second embodiment of the present invention, even when the mask body is bonded to a pair of opposing frames with tension being applied, the strength in the axial direction of a frame being sandwiched between the frames to which the mask body is bonded, is sufficiently large, so that the mask body is stably held. As a result, a high definition vapor deposition pattern is obtained in the vapor deposition.

[0111](11) The frame of the vapor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com