A steel for grade r6 offshore mooring chain with high strength and high toughness and its chain use in anchoring and mooring floating bodies with cathodic protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

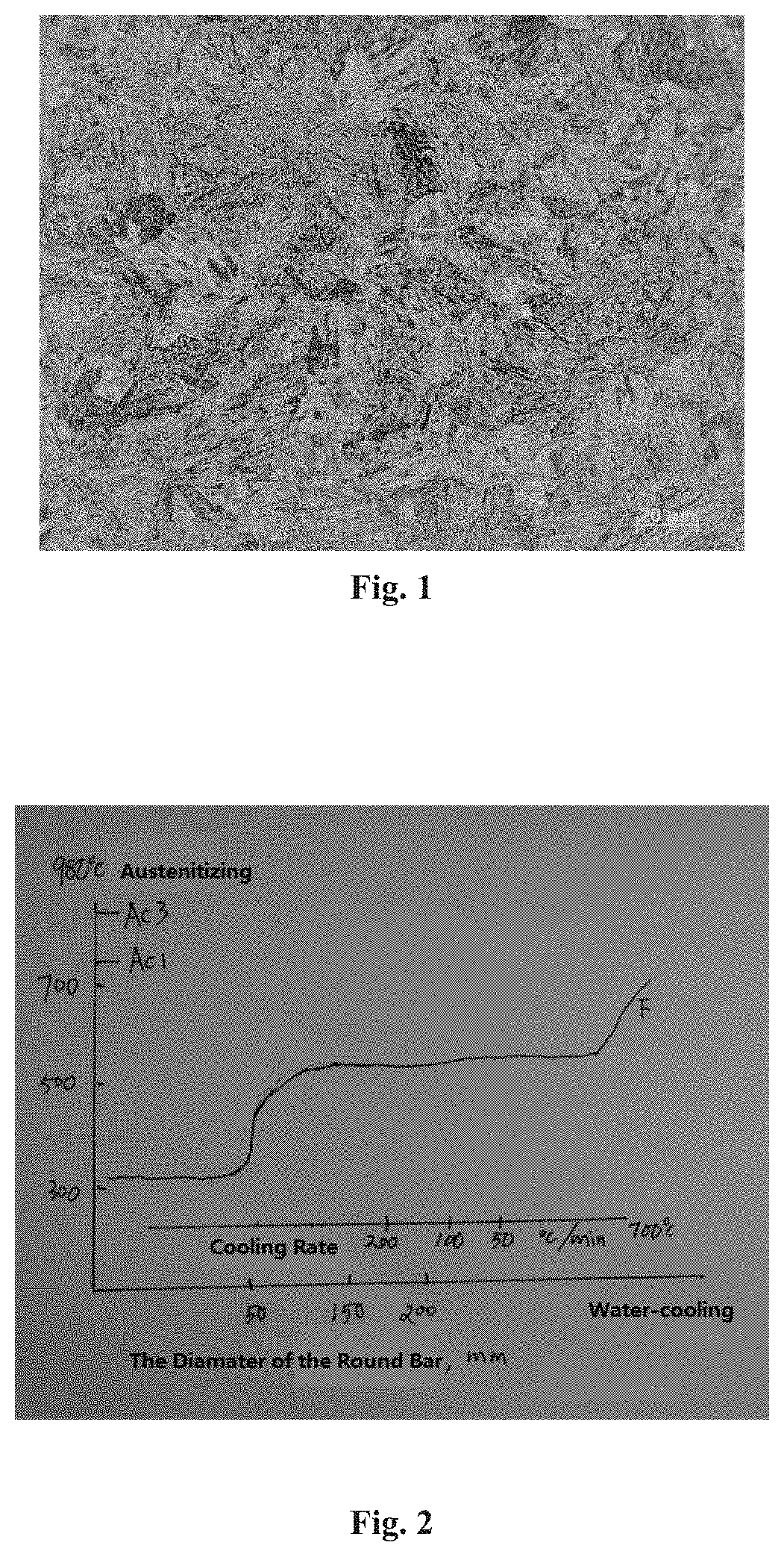

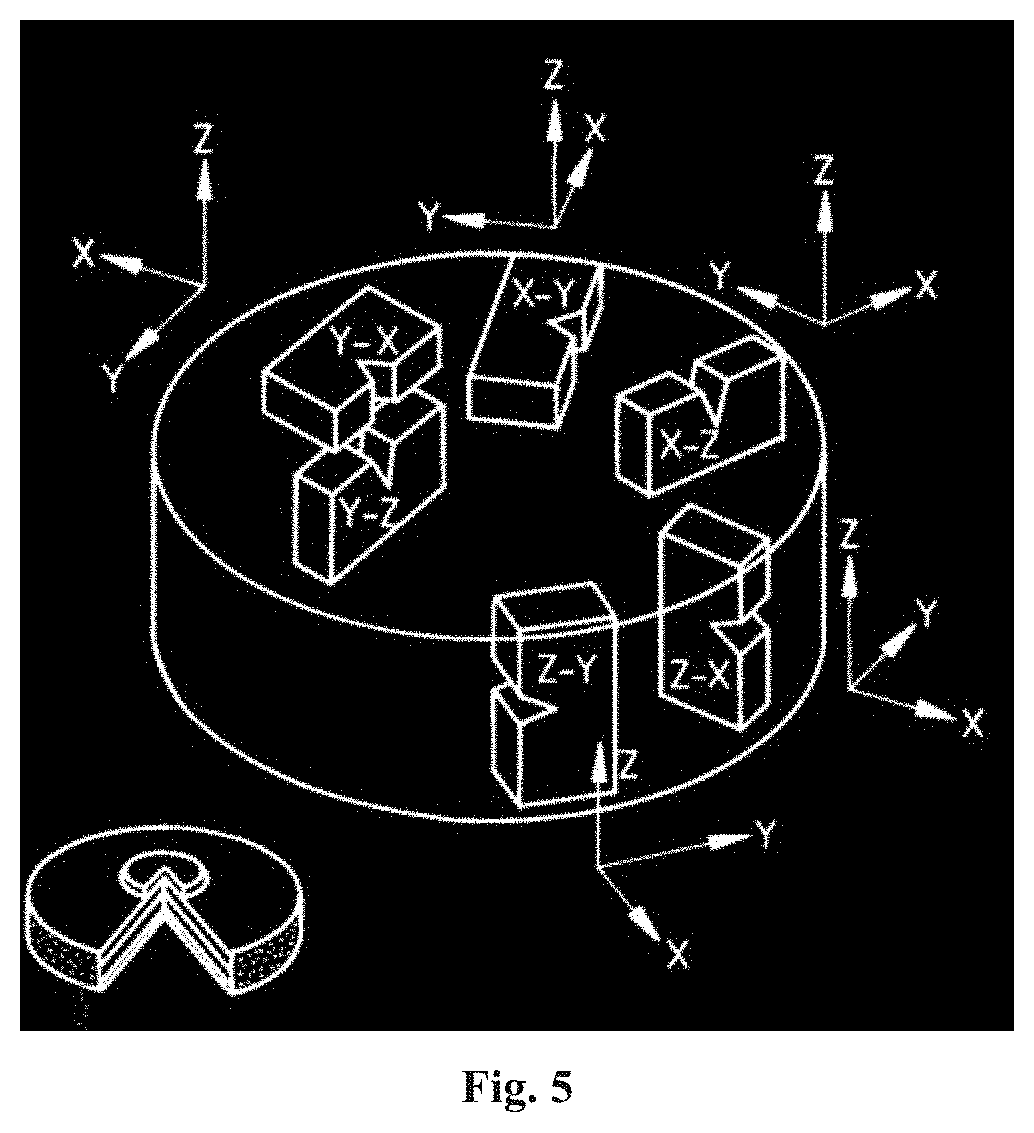

Image

Examples

Embodiment Construction

0]The present invention is further described in detail with reference to carrying out example.

[0071]Carrying out example (invention example) 1-4 and contrast example 3 are about the process wherein continuous casting bloom with tire size of 390×510 mm are rolled into the round bars with a diameter of 120 mm, while contrast example 1, 2 and 4 are about the process that 420 kg test ingots are forged into round bars with a diameter of 95 mm, and then the round bars are processed in sequence by blanking, heating, bending, flash welding, forming chain and heat treatment (quenching+tempering) to obtain the finished chain. The performance data is the average value of the results of three groups of specimens. Numerical treatment of the third place after the decimal point: ≤discard and ≥6 into 1.

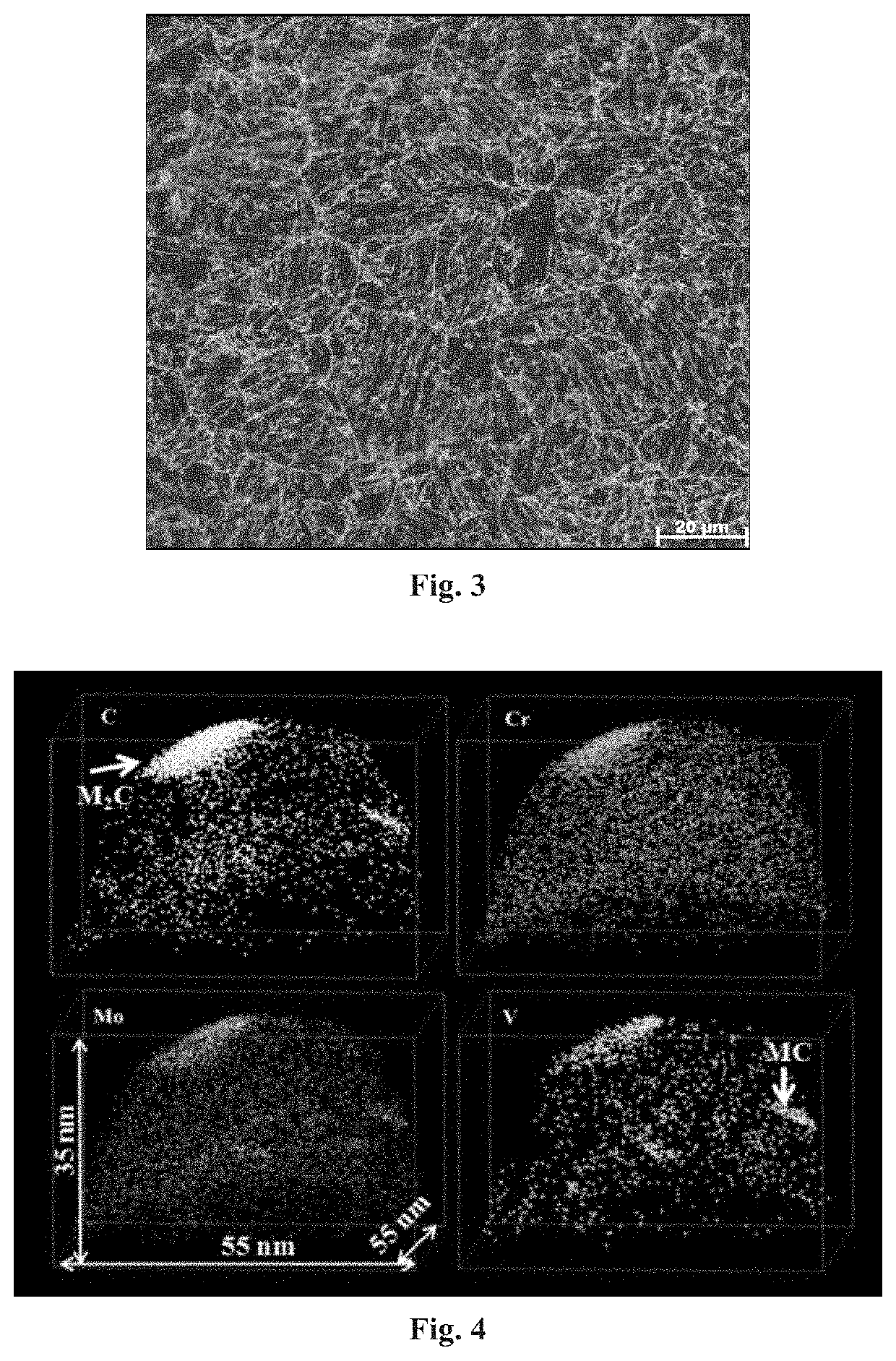

[0072]See Table 2 for the chemical composition of carrying out example 1 to 4 and contrast examples 1 to 4. See Table 3 for process parameters and performance of the chain, and see Table 4 for the si...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com