Dimer fatty acid-polyester diol-based polymer, containing isocyanate groups

a polymer and isocyanate technology, applied in the direction of adhesives, polyurea/polyurethane adhesives, adhesive types, etc., can solve problems such as production and application, and achieve the effect of improving the adhesion of adhesives

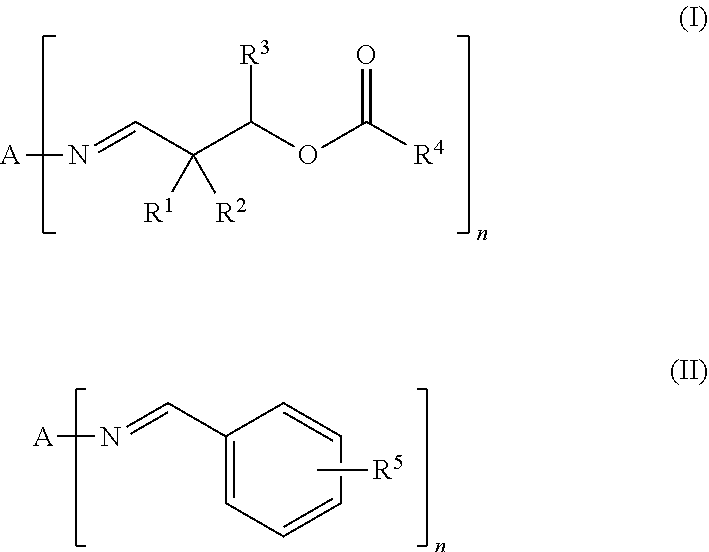

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0182]Working examples are adduced hereinafter, which are intended to elucidate the invention described. The invention is of course not limited to these described working examples.

[0183]“Standard climatic conditions” (“SCC”) refer to a temperature of 23±1° C. and a relative air humidity of 50±5%.

[0184]Unless otherwise stated, the chemicals used were from Sigma-Aldrich Chemie GmbH.

[0185]Polyols Used:[0186]Priplast® 1837: dimer fatty acid-based amorphous polyester diol, OH number 110 mg KOH / g, liquid at room temperature (from Croda)[0187]Priplast® 1838: dimer fatty acid-based amorphous polyester diol, OH number 56 mg KOH / g, liquid at room temperature (from Croda)[0188]Priplast® 3196: dimer fatty acid-based amorphous polyester diol, OH number 37 mg KOH / g, liquid at room temperature (from Croda)[0189]Priplast® 3197: dimer fatty acid-based amorphous polyester diol, OH number 56 mg KOH / g, liquid at room temperature (from Croda)[0190]Desmophen® 5031 BT: glycerol-started ethylene oxide-term...

PUM

| Property | Measurement | Unit |

|---|---|---|

| cone diameter | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com