Colored photosensitive resin composition and multilayer cured film prepared therefrom

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

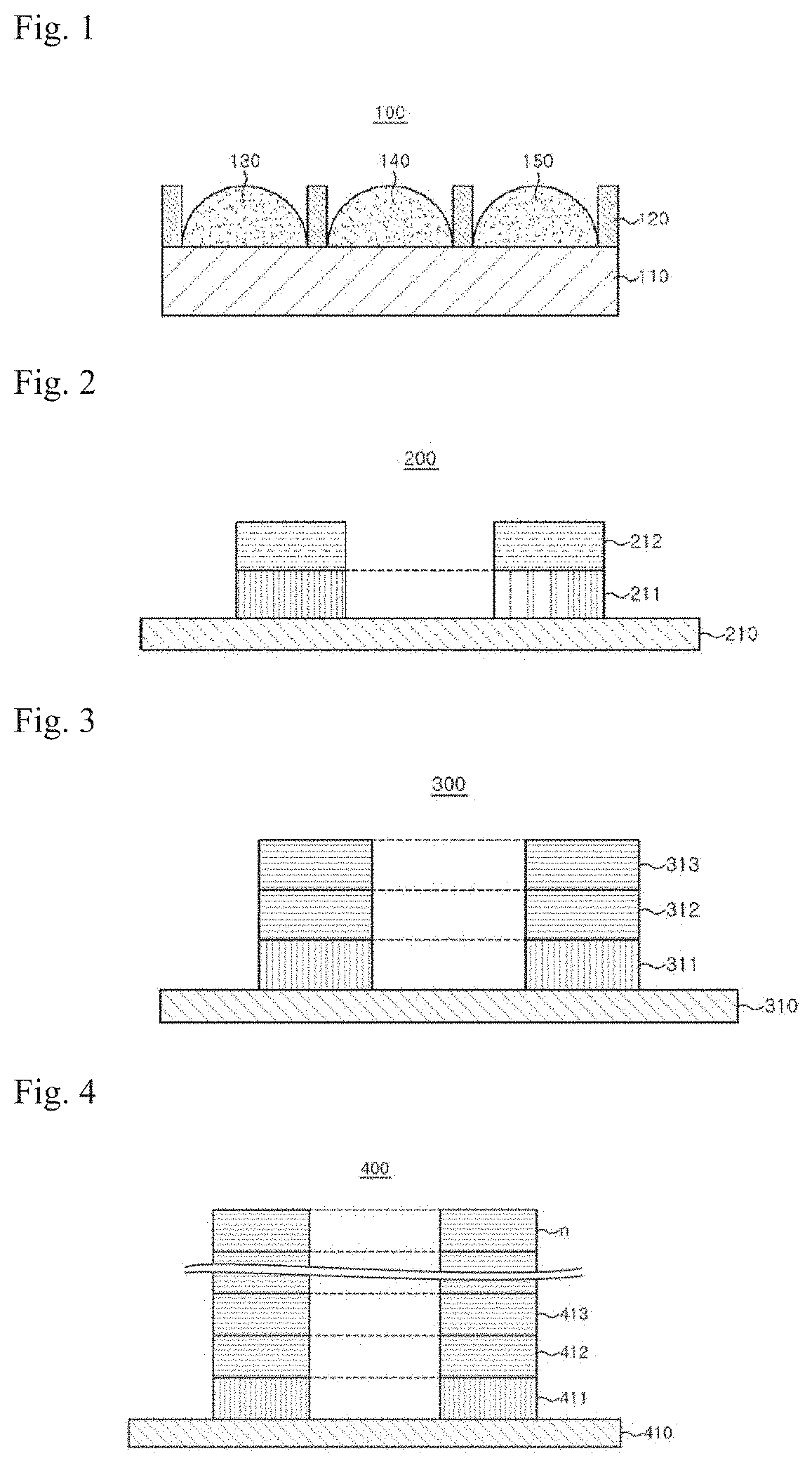

Method used

Image

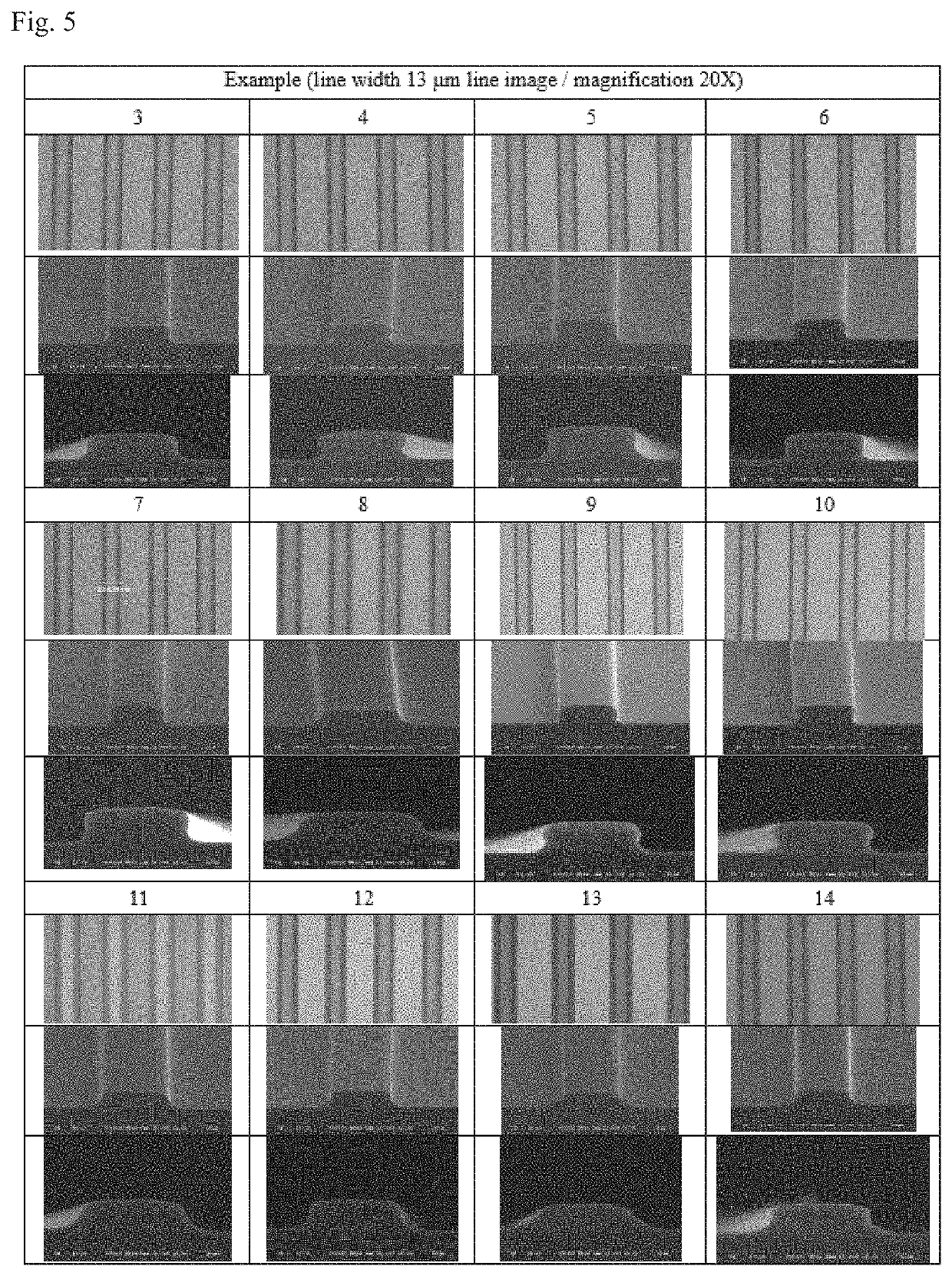

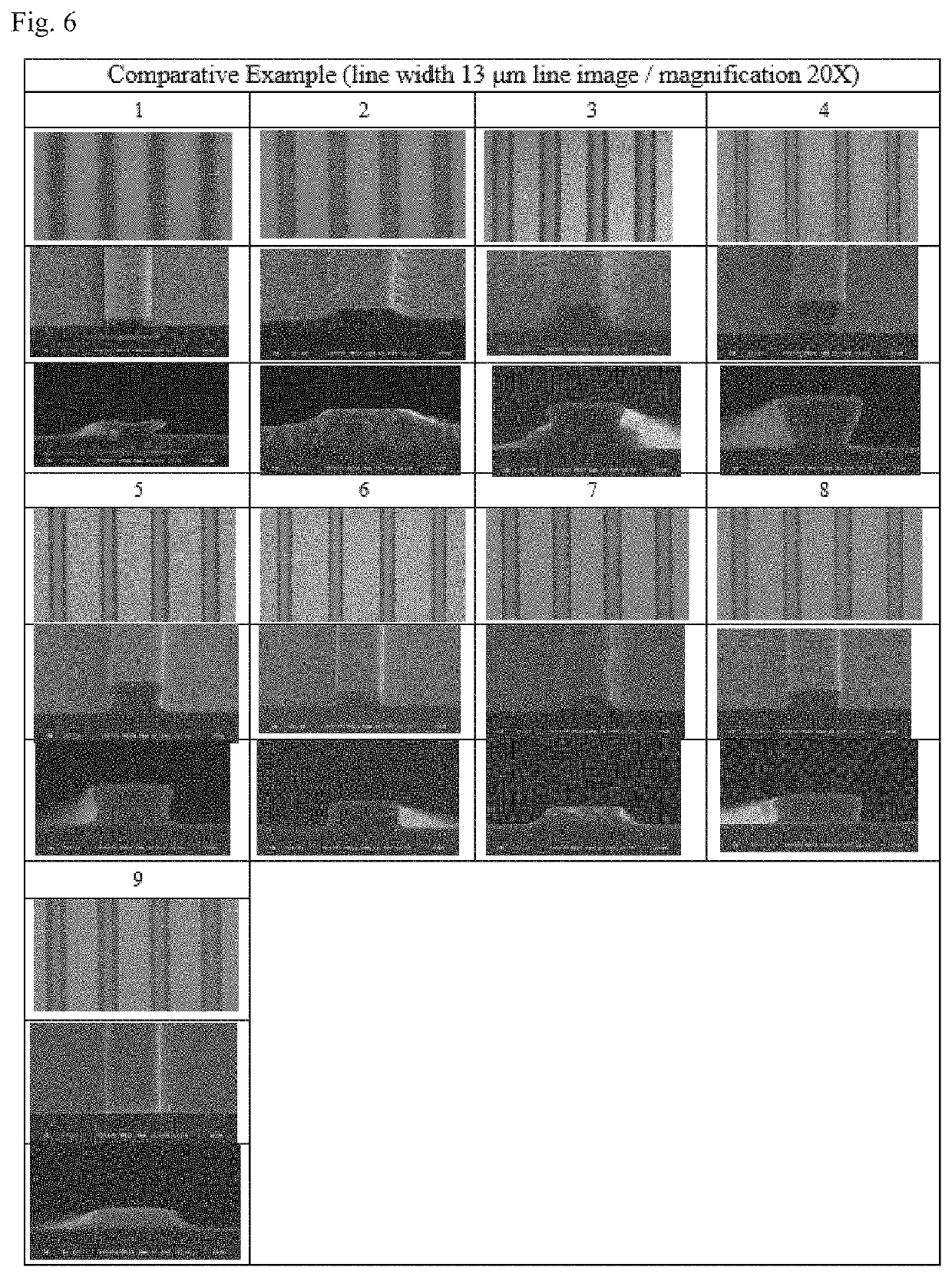

Examples

example

Preparation Example 1: Preparation of a First Copolymer (A1-1)

[0248]A 500-ml, round-bottomed flask equipped with a refluxing condenser and a stirrer was charged with 100 g of a monomer mixture composed of 23% by mole of methacrylic acid, 43% by mole of styrene, 9% by mole of glycidyl methacrylate, and 25% by mole of methyl methacrylate, along with 2 g of 2,2′-azobis(2,4-dimethylvaleronitrile) as a radical polymerization initiator, which mixture was dissolved in 300 g of propylene glycol monomethyl ether acetate (PGMEA). Thereafter, the liquid mixture was heated to 70° C. and stirred for 5 hours for polymerization to obtain a copolymer A1-1 having a solids content of 31% by weight. The copolymer A1-1 thus prepared had a weight average molecular weight of 12,000 Da, an acid value of 100 mg KOH / g, and a polydispersity (Mw / Mn) of 2.80.

preparation example 2

t Copolymer (A1-2)

[0249]The same procedures as in Preparation Example 1 were carried out to prepare a copolymer A1-2 having a solids content of 31% by weight, except that the kinds and contents of the monomers were changed as shown in Table 1 below. The copolymer A1-2 thus prepared had a weight average molecular weight of 14,000 Da, an acid value of 100 mg KOH / g, and a polydispersity (Mw / Mn) of 2.48.

preparation example 3

nd Copolymer (A2-1)

[0250]The same procedures as in Preparation Example 1 were carried out to prepare a copolymer A2-1 having a solids content of 31% by weight, except that the kinds and contents of the monomers were changed as shown in Table 2 below. The copolymer A2-1 thus prepared had a weight average molecular weight of 14,100 Da, an acid value of 100 mg KOH / g, and a polydispersity (Mw / Mn) of 3.23.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com