System and method for recording digital data on glass master recording disks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

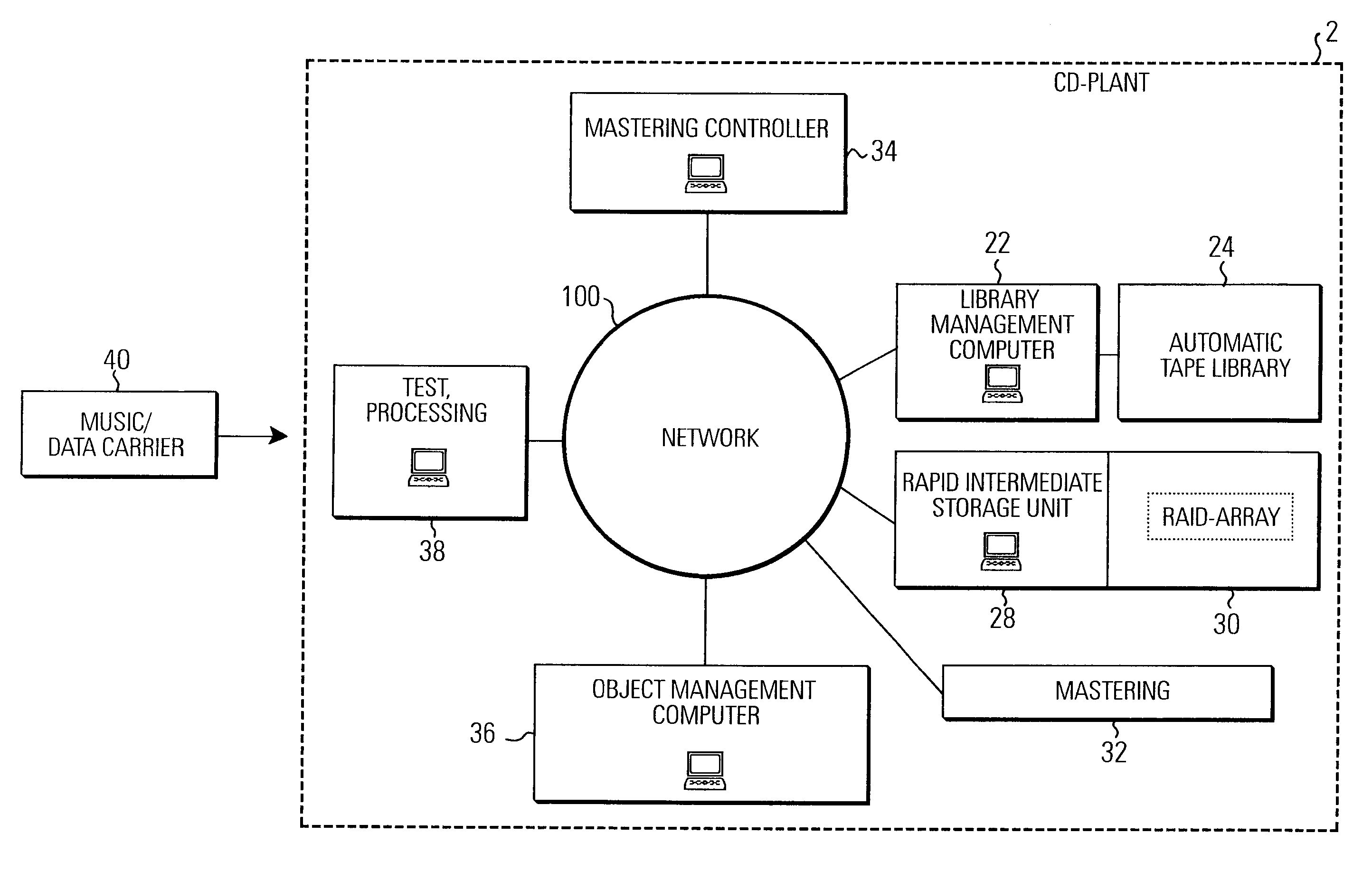

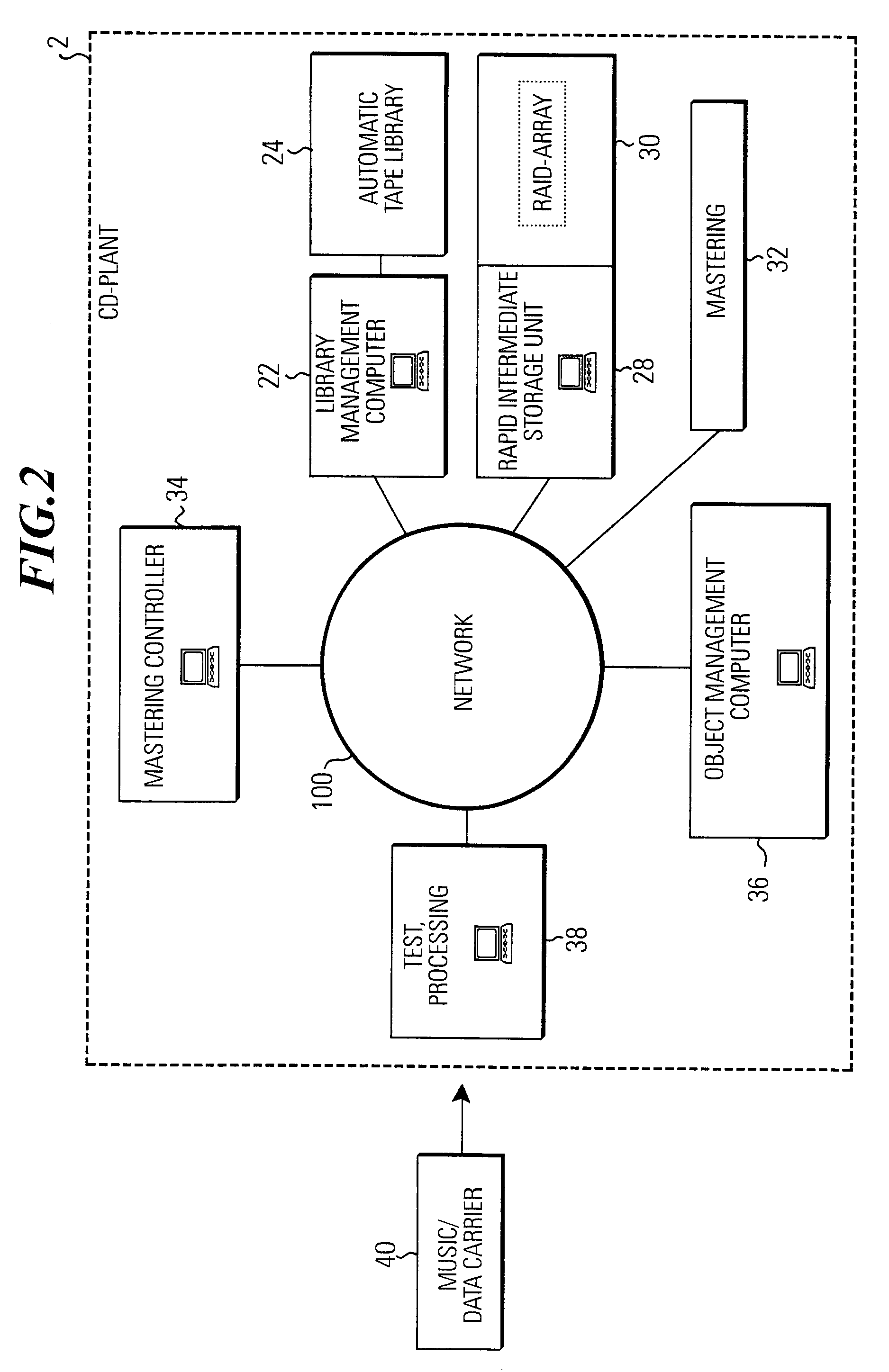

A preferred example embodiment of the present invention will now be explained with reference to FIG. 2 on page 38.

General

The concept described is based on a client server architecture incorporating TCP-IP as the network protocol and NFS as the network file system. A RAID array equipped with a UNIX-compatible cache server handles short-term storage of useful and control information for mastering, inputting files from the checking and processing stations and providing defined minimum data rates to the laser-beam recorders. Long-term storage of useful and control information completed in processing, not immediately required in mastering, is held in an automated tape library having a capacity of several terabytes. Management of the contents stored therein is handled by a standard tape-management software, specific to the type of tape library concerned, installed on a UNIX-compatible library management computer. All mass storages contained in the network are tied to hierarchial storage m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com