Carpet cleaning machine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

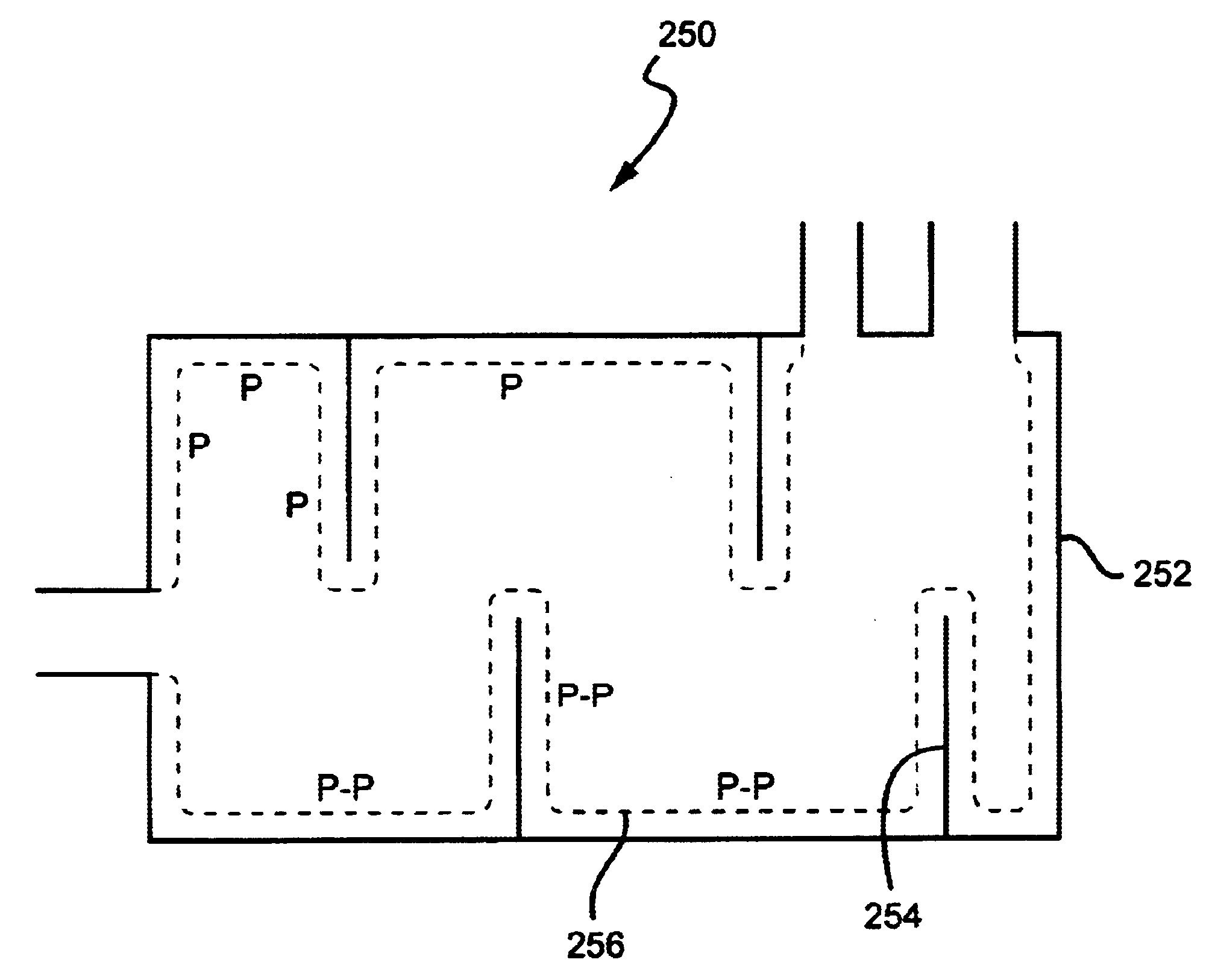

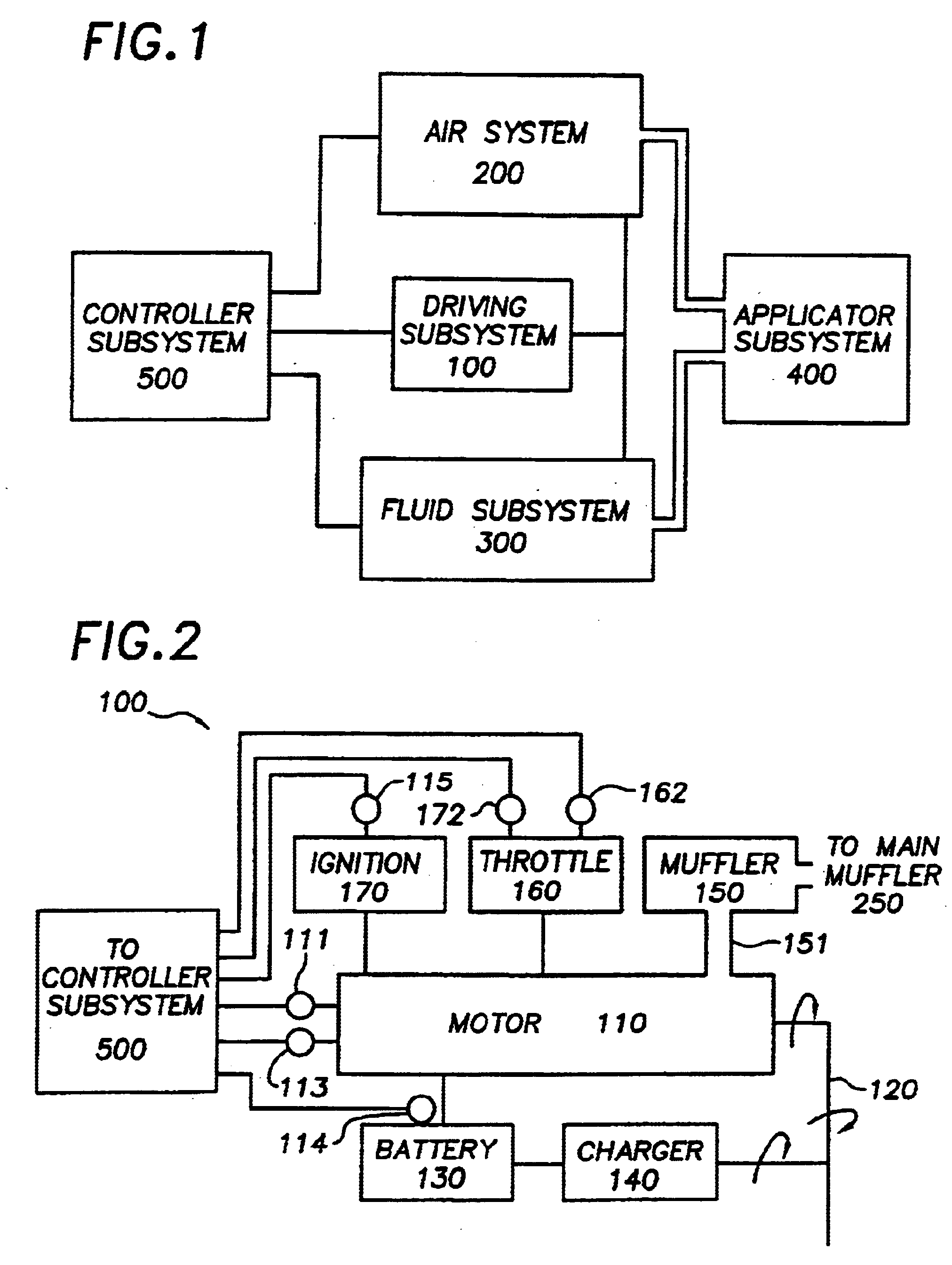

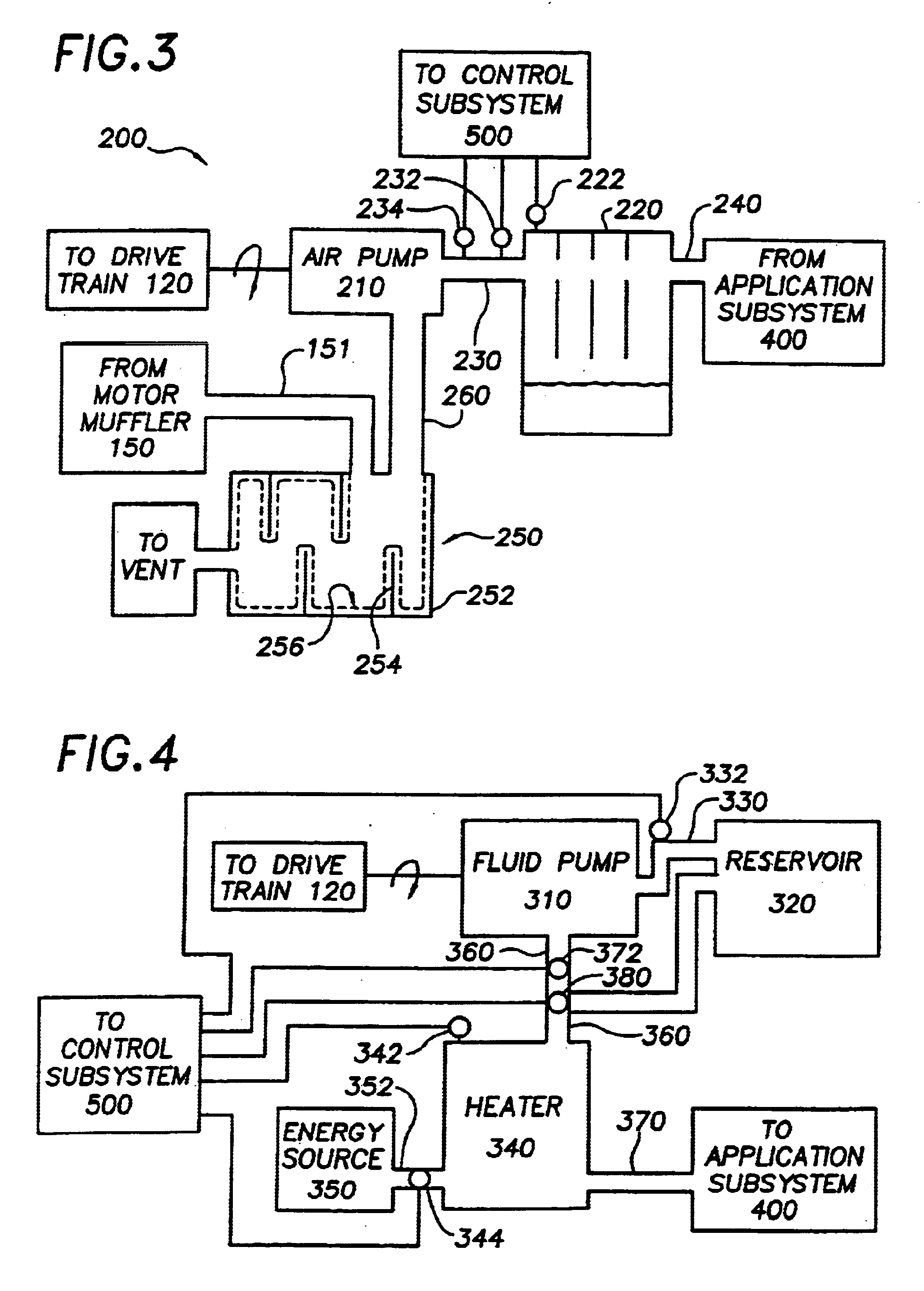

FIG. 1 generally depicts a carpet cleaning machine 1 comprising a power subsystem 100, an air subsystem 200, a fluid subsystem 300, an applicator subsystem 400 and a controller subsystem 500.

Turning to each subsystem in greater detail, FIG. 2 depicts additional details of the driving subsystem 100, which comprises a motor 110, a drive train 120 a battery 130, a charging circuit 140, a motor muffler 150, a throttle 160 and an ignition 170.

The motor 110 is preferably an overhead cam Kohler.TM. gasoline engine, although engines from other manufacturers may function as well, and other types of engines such as propane, diesel or electric would also work. It is contemplated that the motor 110 would range from about 16 hp to about 50 hp, with a preferred rating of about 25 hp. The motor speed is also not critical, as long as the motor 110 can be geared to provide a rotational speed to the air pump of at least about 900 rpm. A preferred speed of the motor is 3600 rpm.

The preferred driving s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com